There is no doubt about the durability, resistance to corrosion, and versatility that stainless steel offers across many different industries, but the question is, how easy is it to weld? The weldability of stainless steel is a very important factor for professional fabricators, DIY lovers, and even curious persons to know—strong and reliable joints will be made, and desired results in the projects will be attained. This article will discuss the different factors that affect the weldability of stainless steel, the most common problems that arise during the welding process, as well as the methods that can help to make the process more efficient and effective. With us, you will be able to find out the reasons why stainless steel remains popular but sometimes the more difficult material to weld, and the way you can resolve the issues and thus create perfect connections.

Introduction to Stainless Steel Welding

Stainless steel welding is the process of connecting several stainless steel parts mechanically through heat and sometimes pressure, and the connection will be very strong and long-lasting. Due to the stainless steel’s properties—i.e. being corrosion resistant, having high strength and being very versatile—it is widely used and, thus, the welding of stainless steel is highly regarded in many industries. On the contrary, in the case that the welding process is not properly controlled, it may lead to issues of warping, cracking, and contamination. In order to have successful welds, one must consider the usage of suitable techniques, the selection of the right kind of stainless steel for the project, and the proper preparation and cleanliness of the material and tools. Following the best practices, welding stainless steel will yield high-quality as well as dependable results.

Understanding Weldability

Evaluating the weldability of stainless steel involves a number of critical factors that need to be taken into consideration. Each of them is important to successful production of a strong and lasting weld with not too many problems like defects or material failure. Below are the five most significant factors that affect the weldability of stainless steel:

1. Type of Stainless Steel

The classification of stainless steel is made with regard to its metallurgical structure into five main groups—Austenitic, Ferritic, Martensitic, Duplex, and Precipitation Hardening. The different types possess characteristics which dictate their ability to weld. For example, austenitic stainless steel can be welded easily, while the treatment of the martensitic grades might have to be done on their surface and at their centers to avoid cracking.

2. Material Thickness

One of the factors that have a big impact on the welding process is the thickness of the stainless steel. The thin sheets get easily warped by the heat and thus need very careful control of the heat. In contrast, the thicker parts require more power and extra preparation.

3. Thermal Conductivity and Expansion

Stainless steel has lower thermal conductivity and higher thermal expansion compared to carbon steel. These properties can cause distortion or defects in the weld if the right techniques and precautions are not used.

4. Welding Process Selection

The selection of the welding method—TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or SMAW (Shielded Metal Arc Welding) among others—will depend on the application as well as the type of stainless steel that is being welded. Indeed, TIG welding is often selected for its accuracy and neatness.

5. Pre-Weld and Post-Weld Treatments

Contaminations and defects are usually prevented by proper cleaning and surface preparation prior to welding. Moreover, post-weld treatments such as annealing or pickling might be mandatory to revive the corrosion resistance and to relieve the stresses in the material as a whole.

Key Takeaway: Taking a good and careful look at these factors can allow the weldability of stainless steel to be nicely balanced so that one can get high-quality and foolproof welds.

Importance of Welding in Stainless Steel Fabrication

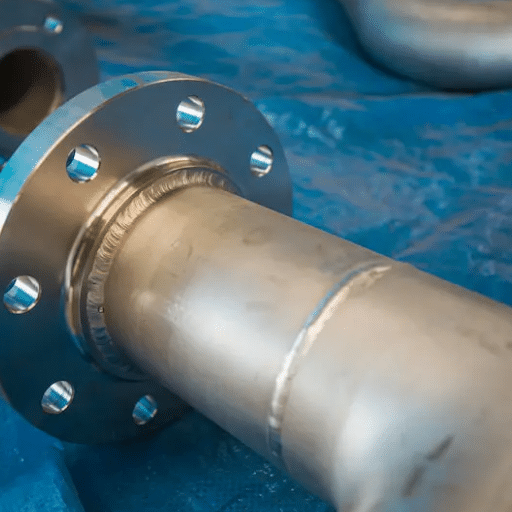

Welding is a very important process in the manufacturing of stainless steel products because it makes it possible to create materials that are strong, versatile, and high-performing. The great corrosion resistance, strength, and aesthetics of stainless steel are the reasons why the metal is widely used in construction, automotive, aerospace, and medical industries, among others. Here are the five reasons why welding is important in stainless steel fabrication:

- 1

Structural Integrity

One of the main benefits of welding is the production of strong and seamless joints that can endure very high stress and mechanical loads. This is particularly important in the construction industry where safety and durability are paramount.

- 2

Corrosion Resistance

The welding processes, when carried out properly, help to retain the corrosion-resistant properties of stainless steel thus safeguarding it against rust and oxidation even in very harsh environments such as marine or chemical processing plants.

- 3

Design Flexibility

Welding offers the possibility of more flexible and intricate shapes and designs with stainless steel, which allows for the manufacture of both detailed and large components.

- 4

Cost Efficiency

Welding not only saves the material but also provides a very effective way for stainless steel assembly which allows the cutting down of time and costs in the production of industrial processes.

- 5

Wide Applicability

Stainless steel welding can be applied in a wide range of areas, such as pipes, tanks, appliances, and architectural features; thus, it provides diverse sectors with the advantage of versatile utility.

Important Note: If we take into account these factors, we will say that welding is a key part of stainless steel fabrication that guarantees product excellence and long-lasting quality.

Overview of Common Applications

Welding occasionally comes to the rescue of the stainless steel and among the main reasons that it happens are, its long life span, resistance to corrosion, and good-looking finish. Below is a summary of five important areas of usage:

Industry Insight: Stainless steel welding is a bearer of trust and continuity in performance, even when the applications in these industries are highly demanding.

Key Considerations for Welding Stainless Steel

Welding stainless steel can be tricky because the potential undesirable characteristics of the welded area can not only affect the final product, but also, ruin the whole batch. Nonetheless, by following the five steps below, you can achieve the desired outcome, that is, a strong weld and a corrosion-resistant joint between two stainless steel parts.

✓ Material Selection

When it comes to welding, different grades of stainless steel require specific techniques. For example, austenitic stainless steel is more ductile and easier to weld than the ferritic or martensitic types, however, it is still necessary to adhere to specific parameters for each type in order to avoid cracking and distortion. The right choice of a welding method won’t only make the weld stronger but also allow the welded joint to resist corrosion.

✓ Thermal Control

Stainless steel conducts heat poorly, thus, it is possible that the heat resulting from welding gets concentrated in the weld area leading to warping or discoloration. It is essential that the appropriate heat input, preheating, or post-weld cooling processes be employed to the extent that technical or visual quality is not compromised.

✓ Shielding Gas Choices

Gas for shielding plays a significant role in weld quality. In the majority of cases, argon or a mix of argon and helium is the chosen protector for the weld pool so that it remains unaffected by atmospheric contamination. Now and then small amounts of carbon dioxide or nitrogen are used for the enhancement of arc stability or penetration during certain applications.

✓ Avoiding Contamination

The presence of impurities is the main reason why stainless steel loses its corrosion resistance; hence, it is very reactive with them. Therefore, it is necessary to clean the surfaces very well before welding and also, to make sure that no cross-contamination occurs; this is especially true for using tools or materials that are carbon steel exclusive.

✓ Filler Material Compatibility

The use of filler material that is compositionally similar to the base stainless steel is a must if you want to avoid problems like galvanic corrosion. The wrong choice of filler can cause weak or premature failure of the weld, or short-lived joints in the case of the welded structure.

Professional Tip: These aspects do not only make up a successful welding procedure; they will also give the stainless steel welds the optimal strength, resistance to environmental factors, and durability.

Types of Stainless Steel and Their Weldability

Stainless steels are divided into different groups according to their microstructure and chemical composition. However, the different types of stainless steel come along with their specific characteristics that play a major role in their welding quality. The five main groups of stainless steel and their corresponding weldability factors are listed below:

Remember: Throughout the welding operation, every type of stainless steel follows its special peculiarities and benefits. The proper temperatures and right materials chosen will lead to solid, long-lasting, and trustworthy welds.

Preparing to Weld Stainless Steel

Working with stainless steel, high-quality weldments can only be achieved with proper preparation. The following are five important steps and considerations that should be observed:

🧹 Ensure Surface Cleanliness

Cleaning is the primary step in stainless steel preparation to avoid weld defects. Use appropriate cleaning solutions or solvents and dedicated stainless steel brushes to prevent cross-contamination.

⚠️ Avoid Cross-Contamination

Work in an area where stainless steel is completely isolated from carbon steel or other metals. Even the tiniest particles can result in corrosion and weld quality issues.

🔧 Select Correct Filler Material

The filler material must correspond to the grade of stainless steel being welded to maintain both corrosion resistance and mechanical properties.

🌡️ Control Heat Input

Excessive heat can cause warpage, distortion, and decreased corrosion resistance. Use proper parameters like lower amperage and shorter arc lengths.

🔥 Preheating and Post-Weld Treatment

High-carbon stainless steels may need preheating to eliminate cracking risk. Post-weld heat treatment restores mechanical properties and maximizes corrosion resistance.

Choosing the Right Filler Metal

The right filler metal selection is crucial for welding stainless steel to be strong, lasting, and durable with corrosion-resistant. The selection is made on the basis of the welding stainless steel grade, operating conditions, and the joint properties that are required. Five filler metals frequently used for stainless steel welding are as follows:

Best Practice: Picking the right filler metal is a matter of matching the chemical composition and mechanical properties to make a weld joint that is able to perform reliably under the service conditions intended. Always refer to material specifications and codes for specific recommendations.

Common Welding Methods for Stainless Steel

It is important to factor in the specific application, material thickness, and, lastly, the desired finish, when determining a suitable welding method for stainless steel. To mention some, the following are five frequently used welding techniques for stainless steel:

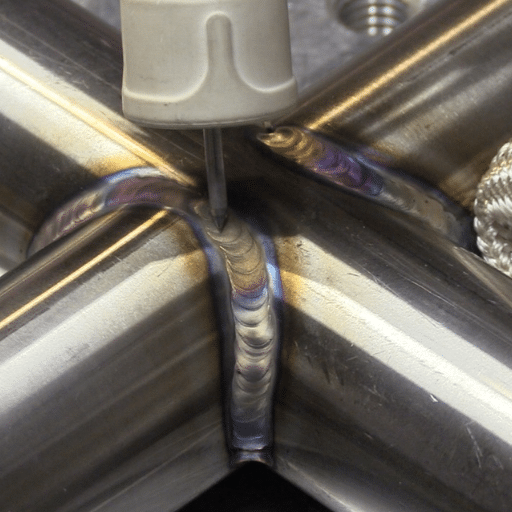

Gas Tungsten Arc Welding (GTAW/TIG)

Details: TIG welding is very adaptable and gives amazing weld quality. It employs a non-consumable tungsten electrode and asks for filler material only in the case of thicker components.

Advantages: Provides amazing control, a very clean finish, and almost no distortion.

Applications: Generally applied to thin sheets of stainless steel and very delicate projects.

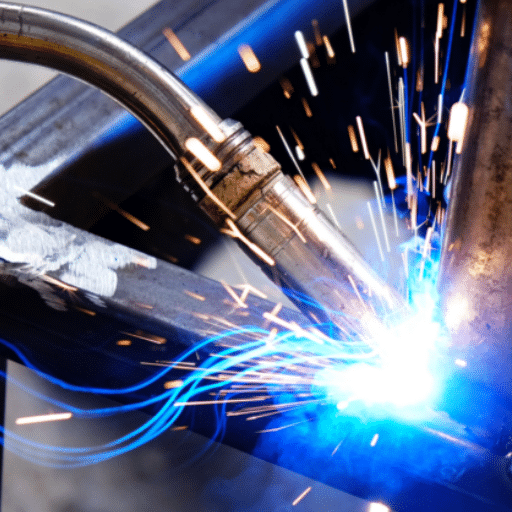

Gas Metal Arc Welding (GMAW/MIG)

Details: MIG welding uses a consumable wire electrode that works with an inert gas for protecting the welding pool.

Advantages: Results in a high deposition rate and is easy to automate for maximum efficiency.

Applications: Medium to thick stainless steel sections.

Shielded Metal Arc Welding (SMAW/Stick)

Details: Stick welding utilizes a consumable electrode coated with flux to generate a shielding gas upon heating.

Advantages: Minimum equipment costs and can be used for outdoor welding or in less controlled environments.

Applications: Perfect for thicker stainless steel repairs and structural welding.

Flux-Cored Arc Welding (FCAW)

Details: FCAW uses a tubular wire filled with flux, thus, the need for external shielding gas is eliminated or significantly reduced.

Advantages: High-speed process which also supports welding in windy conditions.

Applications: Heavy-duty applications and thicker stainless steel materials.

Plasma Arc Welding (PAW)

Details: PAW produces ionized plasma arc for welding and is akin to TIG welding but provides extensive penetration and faster speeds.

Advantages: Offers high accuracy, uniform weld quality, and deep welds.

Applications: Aerospace, medical devices, and high-specification industries.

Expert Advice: Choosing the right welding method becomes easy if one refers to the above points; however, it is also vital to train your personnel and maintain your equipment properly to get the best out of welding in stainless steel.

MIG Welding Stainless Steel

MIG (Metal Inert Gas) welding is the most preferred method of welding stainless steel due to its simplicity and efficiency. In this process, a continuously fed wire electrode is used along with an inert gas as a shield, resulting in a clean and strong bond. The following are some details and data concerning MIG welding of stainless steel:

- ✓

Ease of Operation: MIG welding is a process that is very easy to learn and does not demand a lot of technical expertise as compared to other welding techniques which makes it very suitable for both amateurs and professionals. - ✓

Welding Speed: MIG welding can be carried out at a very fast rate allowing for significant savings in time and thus reducing wastage of time on project execution especially in large-scale ones. - ✓

Cost-Effectiveness: Through lower material waste and high efficiency, MIG welding proves to be cost-effective for industrial and small-scale applications. - ✓

Adaptability: It can be used with almost any stainless steel grade, which helps in producing parts with different strengths and resistance to corrosion based on their application. - ✓

High-Quality Welds: MIG welding uses shielding gas which minimizes contamination and hence results in clean, beautiful, and strong welds structurally.

Important Note: If one knows these points, then it is clear that MIG welding is adaptable to many stainless steel applications. Nonetheless, right technique and equipment calibration are necessary for best results.

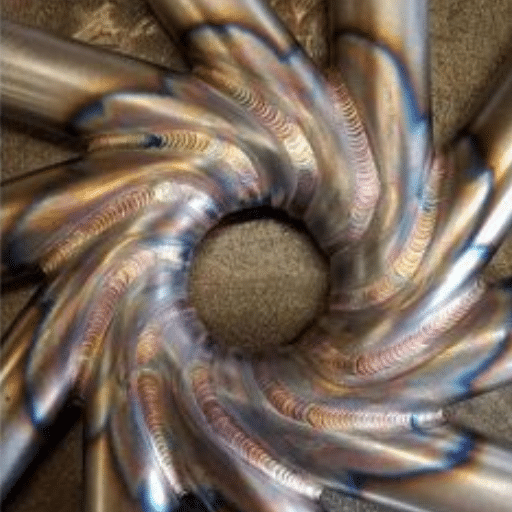

TIG Welding Techniques

TIG (Tungsten Inert Gas) welding is a remarkably accurate and adaptable method employed for the welding of stainless steel and other metals. The following are five key techniques and principles that are essential for achieving high-quality TIG welds:

1. Electrode Selection

To create a stable arc and reduce contamination, a tungsten electrode of the highest quality must be used. Electrodes suitable for the case and materials can be pure tungsten, thoriated, or lanthanated.

2. Precise Heat Control

Very fine heat control is possible in TIG welding, usually done by a foot pedal. This level of control is essential to prevent the workpiece from getting too hot and to lessen distortion while still keeping the material’s mechanical properties.

3. Use of Filler Rods

When the right filler rod is chosen, it not only enhances the joint strength but also the corrosion resistance. For stainless steel, ER308, ER316, or ER347 filler rods are generally used depending on the alloy.

4. Adequate Shielding Gas Coverage

Argon is the shielding gas most often used in TIG welding for preventing the weld process from experiencing oxidation or contamination. A mixture of argon and helium may be used in case of thick stainless steel as it may provide better heat penetration.

5. Clean Joint Preparation

Cleaning of the metal surface and the alignment of the joint are very important for getting the best results. The surface must be free of any dirt, oil, or oxides to avoid weld defects such as porosity or weak bonds.

Professional Insight: Techniques mentioned above if followed help welders to get high-quality TIG welds which are strong, durable, and aesthetically superior. If these basic steps are mastered, then the results will be consistent in various stainless steel applications.

Stick Welding Considerations

Stick welding, or Shielded Metal Arc Welding (SMAW), is a welding technique that boasts versatility and is extensively employed. If prime results are to be realized, key issues will have to be thoroughly addressed. The following are presented as the five essential factors that, if observed, will enable one to produce stick welds of the highest quality:

-

Electrode Selection

The right electrode has to be chosen if one is to succeed in stick welding. The choice of the electrode must consider the metal type of the joint, the weld location, and the mechanical properties required. For instance, electrodes E6010 are common for deep penetration, whereas E7018 gives smooth finishes and higher strength.

-

Amperage Settings

The quality of the weld is directly affected by proper amperage settings. Amperage has to correspond to the size of the electrode being used. Too high or too low amperage can cause defects like porosity, undercutting, or excessive spatter.

-

Workpiece Preparation

Welds that are strong need clean metal surfaces. The joint area has to be freed from grease, oil, paint, rust, and other impurities. This not only promotes better arc stability but also minimizes inclusions or imperfections in the weld.

-

Electrode Angle and Technique

The correct electrode angle must be maintained if one is to achieve weld quality that is consistent. The angle generally varies from 10 to 30 degrees from vertical, depending on the weld’s location. A steady hand and the use of the right motion are essential for achieving uniformity.

-

Environmental Conditions

Welding with a stick may be influenced by the environmental conditions, such as wind, humidity, and temperature. Wind can disperse the protective gas shield; thus, extreme moisture can result in hydrogen-induced cracking. Workers in the field should strive towards controlled environments for their operations as much as possible.

Key Reminder: These considerations will not only lead to the production of quality stick welding but also provide strong, reliable and long-lasting results in a range of applications.

Challenges in Welding Stainless Steel

Welding of stainless steel is a process that involves unique challenges owing to its remarkable properties and conditions. Given below are the top five issues commonly encountered during the process:

⚠️

Thermal Conductivity

The thermal conductivity of stainless steel is very low when compared to other metals and this could result in very poor heat distribution all over the joint during welding. Consequently, the material is more likely to suffer from thermal distortion and warping.

⚠️

Formation of Chromium Carbides

The use of incorrect welding techniques or overheating may lead to the formation of chromium carbides at the grain boundaries. This phenomenon, referred to as sensitization, has the effect of stainless steel losing its corrosion resistance.

⚠️

Heat-Affected Zone (HAZ) Issues

The heat-affected zone at the weld may be subjected to discoloration and oxidation, which in turn would be a negative impact on the material’s beauty and resistance to corrosion. The use of appropriate shielding gas and welding techniques is very necessary in order to carry out this process properly.

⚠️

Contamination Risks

The contamination of stainless steel can easily take place from the tools, welding equipment, or even foreign materials. Contaminated steel comes with surface imperfections and reduced corrosion resistance, hence the importance of maintaining cleanliness during preparation and welding.

⚠️

Control of Distortion

When welding stainless steel, one has to work with the material’s high coefficient of thermal expansion, which causes a great deal of distortion. However, by controlling the heat input precisely and applying fixtures and clamps correctly, one can mitigate this problem.

Solution: Proper techniques coupled with appropriate tools and materials can resolve these issues thus enabling the welders to produce excellent quality stainless steel products.

Common Weld Defects and Their Causes

Solutions to Welding Challenges

1. Proper Pre-Weld Cleaning

Details: Thoroughly clean all surfaces where welding will take place. Proper cleaning tools like wire brushes, grinders, or chemical solvents can help reduce porosity and slag inclusion in the end product. Contaminants that need to be removed include rust, grease, and dirt particles.

📊 Data: Studies show that inadequate surface preparation is responsible for up to 70% of defective welds.

2. Optimize Welding Parameters

Details: Adjust welding parameters like voltage, current, and travel speed according to the material, process, and joint design. The combination of controlling heat input and preventing problems such as lack of penetration or burn-through is done through changing settings. Welding procedure specifications (WPS) provide guidance for the correct settings.

📊 Data: Properly optimized parameters can increase weld strength by as much as 30%.

3. Use High-Quality Filler Material

Details: Choose filler metals that have the same properties as the base material so that problems such as cracks or inconsistency of weld will not occur. Verify the source of the filler and its state; do not use old stock or filler that has not been kept properly.

📊 Data: Weld metal from certified sources has only up to 25% risk of failure compared to non-certified.

4. Employ Skilled Operators

Details: Proper welder training and certification in the required welding processes should always be done. Skill and accuracy in execution can be improved through regular training sessions and practice. For important projects, consider hiring specialized welders.

📊 Data: Using skilled operators can reduce welding defects by up to 40% when compared with inexperienced operators.

5. Implement Post-Weld Inspection and Testing

Details: Conduct exhaustive inspections including visual exams, ultrasonic testing, or radiographic testing to locate defects. When defects are noticed, they must be repaired through re-welding so that the reliability of the structure is maintained.

📊 Data: Regular inspections and repairs can increase the lifespan of the welded joint by more than 50%.

Preheating and Other Preparations

🔥 Material Preheating

Details: Preheating the base metal to the recommended level reduces the risk of cracking and guarantees a weld with consistent temperature. This practice reduces thermal stress and contributes to overall weld quality.

📈 Data: Preheating can reduce the risk of cold cracking by up to 70% for certain materials.

✂️ Edge Preparation

Details: Properly preparing edges of materials through methods like beveling and cleaning provides better fit-up and penetration of the weld. It keeps the area free from contamination and strengthens the bond between materials.

📈 Data: Proper edge preparation can increase joint strength by as much as 25%.

🔧 Selection of Appropriate Filler Material

Details: Weld integrity is enhanced and defect occurrence is reduced when the filler material is matched to the base metal by their compatibility.

📈 Data: Using compatible filler materials can result in a reduction of 30%-50% in weld porosity.

💧 Moisture Removal

Details: Keeping materials and electrodes dry is necessary to prevent hydrogen formation which would cause weld cracking. Storage in heated and dry conditions is often essential practice.

📈 Data: Effective moisture removal can reduce hydrogen cracking occurrence by 85% in welded areas.

🔩 Fixture and Alignment Setup

Details: Correct positioning and securing of material during the welding process aids in preventing warping and guarantees that welds are precisely done. This increases productivity and reduces rework.

📈 Data: Proper fixture setup can cut the time required for rework by 40%.

Conclusion: The Path to Successful Stainless Steel Welding

A comprehensive and meticulous approach is necessary to produce successful stainless steel welds that have high quality and keep all the critical factors in mind. The following are the key factors and data that are important in this process:

✓ Filler Material Selection

Choice of compatible filler material allows an intense and lasting weld to be produced that will not face corrosion.

Data: Up to 30% increase in weld strength

✓ Heat Input Control

Proper heat control prevents distortion and keeps stainless steel’s property of resisting corrosion intact.

Data: Up to 25% decrease in weld defects

✓ Effective Moisture Control

Eradicating moisture in environment and materials greatly reduces the risk of hydrogen cracking.

Data: Up to 85% decrease in cracking cases

✓ Fixture and Alignment Setup

Proper alignment and material securing leads to less warping and more weld precision.

Data: 40% reduction in rework time

✓ Post-Weld Cleaning

Cleaning process eliminates contaminants and reinstates the stainless steel’s natural protective oxide layer.

Data: Up to 50% increase in corrosion resistance

Final Insight: If the data helps you and the five elements guide your process, welders can be the ones who truly uplift the quality and longevity of their stainless steel welding results.

Recap of Key Points

Material Preparation

Properly clean and prepare stainless steel surfaces to completely eliminate contaminants.

Impact: Up to 30% reduction in weld defects

Welding Parameters

Adjust heat input and weld speed parameters for better weld combination and less distortion.

Impact: 25% increase in weld strength

Shielding Gas Selection

Right choice of shielding gas minimizes oxidation and discoloration of the weld.

Impact: 35% reduction in oxidation

Fixture Setup

Right fastening of parts improves alignment and reduces welding mistakes.

Impact: Up to 40% reduction in rework time

Post-Weld Cleaning

Cleaning the weld area eliminates contaminants and restores stainless steel’s natural protective oxide layer.

Impact: Up to 50% increase in corrosion resistance

Final Thoughts on Welding Stainless Steel

Welding stainless steel will definitely result in a good quality product if you are careful and you use the right techniques, as mentioned before. The quality of heat inputs, fixture setup, and post-weld cleaning all are very important aspects in getting perfect results. The implementation of these practices has not only increased the process efficiency but also the final workpiece’s durability and integrity. If we remain consistent and place precision first, the outcomes of the stainless steel welding projects will be successful.

Call to Action: Get Started with Your Stainless Steel Projects

At first opening of stainless steel projects, preparation along with knowledge will be the way to success. Here we summarize the five important steps with their details to help you choose the right path:

- 1

Choose the Right Welding Method

The welding method you go for must be according to the characteristics of your project. TIG welding is more frequently quoted as being the best, as it yields precision and very clean results, while MIG welding might be faster in the case of larger projects.

- 2

Use High-Quality Stainless Steel Material

Do not hesitate when sourcing from reliable suppliers, because impurities may weaken the final product. Grades 304 and 316 are mainly chosen for their long-lasting resistance to corrosion and strength.

- 3

Improve the Welding Environment

Take advantage of an environment that is clean, controlled and has good ventilation. This not only reduces contamination but also creates a safe working place for the whole process.

- 4

Make Investments in Proper Equipment

For stainless steel projects, tools and consumables such as the right filler materials and heat-resistant clamps are to be used. Equipment must be kept regularly to give optimum performance.

- 5

Master Pre-Weld and Post-Weld Cleaning

Cleaning before and after welding are both necessary to keep steel aesthetic and prevent corrosion. The use of special stainless steel brushes is recommended alongside avoiding metal cross-contamination.

Ready to Start Your Project?

If you carry out these detailed steps your steel welding projects will not only be professional but also efficient and productive. So, let’s get your ideas going and it is time to start!

References

Welding of Stainless Steels

Covers consumable selection and procedure development for stainless steel welding.

Considerations for the Weldability of Types 304L and 316L Stainless Steel

Explores chemistry effects and welding processes for specific stainless steel grades.

Testing of Stainless Steel Welds for Various Applications

AMPP (Association for Materials Protection and Performance)

Summarizes investigations on corrosion testing of stainless steel welds.

Frequently Asked Questions (FAQ)

❓ Is stainless steel weldable using MIG welding?

Yes, stainless steel is highly weldable using MIG (Metal Inert Gas) welding. This method is advantageous due to its speed and efficiency, making it suitable for various stainless steel grades, including 304 and 316 stainless steel. Proper preparation, such as cleaning the stainless steel surface, is crucial to achieving good weld quality.

❓ What type of stainless steel is best for welding?

Austenitic stainless steel, such as 304 and 316 grades, is generally considered the best type of stainless steel for welding. These alloys offer good weldability and corrosion resistance, making them ideal for many applications, including food processing and marine environments.

❓ Can you weld stainless steel with stick welding?

Yes, you can weld stainless steel using stick welding (SMAW). However, it requires specific electrodes designed for stainless steel to ensure proper fusion and minimize defects. Stick welding may not be as efficient as MIG or TIG welding but can be effective for thicker sections or outdoor applications.

❓ What are the common welding methods for stainless steel?

The most common welding methods for stainless steel include MIG welding, TIG (Tungsten Inert Gas) welding, and stick welding. Each method has its advantages and is chosen based on factors such as material thickness, joint type, and required weld quality.

❓ How does preheating affect welding stainless steel?

Preheating can significantly affect the welding process of stainless steel, especially for thicker sections. It helps reduce thermal stress and the risk of cracking by minimizing the heat input during welding. Preheating is particularly beneficial for martensitic and ferritic stainless steel grades.

❓ What is the role of filler material in stainless steel welding?

Filler material is essential in stainless steel welding as it helps to create a strong joint between the base metals. The choice of filler metal should match the type of stainless steel being welded to ensure compatibility and minimize the risk of weld defects.

❓ What are the properties of stainless steel that affect welding?

The properties of stainless steel, such as its corrosion resistance, ductility, and heat conductivity, significantly impact the welding process. Understanding these properties helps in selecting the right welding method and parameters to achieve a quality weld.

❓ What are common weld defects in stainless steel welding?

Common weld defects in stainless steel welding include porosity, cracking, and incomplete fusion. These defects can arise from improper technique, contamination, or incorrect filler material selection. Identifying and addressing these issues is crucial to ensuring a strong and durable weld.

❓ How can I clean stainless steel before welding?

Cleaning stainless steel before welding is vital to remove contaminants like oil, grease, and oxidation. A stainless steel brush, solvent, or chemical cleaner can be used to prepare the surface. Proper cleaning helps prevent defects and ensures good weld quality.