In both industrial and residential piping systems, high-quality fittings are the reliable and efficient mainstay. Stainless steel nipples are among these essential items and enjoy the greatest popularity due to their exceptional strength, resistance to corrosion, and ability to be used in many different applications. As a reputable maker of stainless-steel nipples, we are glad to offer pipe fittings that are precisely engineered to fulfill the strictest industry standards. This post will highlight the main advantages of stainless steel nipples, their diverse uses, and the factors that differentiate a premium manufacturer from the rest. If you are a contractor, plumber, or engineer, this manual will provide you with the necessary information for making wise decisions for your projects. Keep watching as we reveal the vital function that these fittings have in the creation of tough and long-lasting piping systems.

Understanding Stainless Steel Nipples

Stainless steel nipples are the shortest sections of pipe whose ends have threads, and they provide the way to connect two other parts of piping or tubing. Their strength and resistance to rust, along with their suitability for extreme temperature and pressure situations, are some of the qualities for which they are recognized. Fittings made of stainless steel are generally of higher quality, and they find application in various industries like plumbing, construction, oil and gas, and manufacturing. The durability and dependability of such fittings make them a must-have for the creation of secure and efficient piping systems, even under tough conditions.

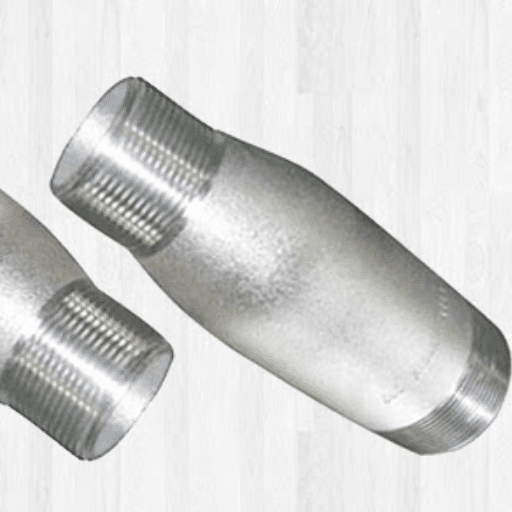

What are Stainless Steel Nipples?

Stainless steel nipples are short pipe segments that are equipped with male-threaded ends, thereby allowing them to be used to connect different pipes or fittings in a piping system. These parts are made from top-grade stainless steel, and as such, they showcase excellent corrosion resistance, prolonged lifetime, and ability to endure high temperatures and pressures. Thus, the usage of stainless steel nipples is not limited to a certain industry but rather spans different industries such as plumbing, oil and gas, construction, and manufacturing due to their versatility. The main function is to connect two pipe sections tightly, thereby allowing the movement of liquids, gases, or other materials in the pipe system. Different sizes, lengths, and threading options are available for stainless steel nipples, making them indispensable for the connection of both residential and industrial applications that are reliable and durable. Their strength and flexibility guarantee their acceptance by engineers and builders all over the world.

Types of Stainless Steel Nipples

Among the many varieties of stainless steel nipples, each type has its own specific quality for every application. A list of stainless steel nipples that are the most common is below.

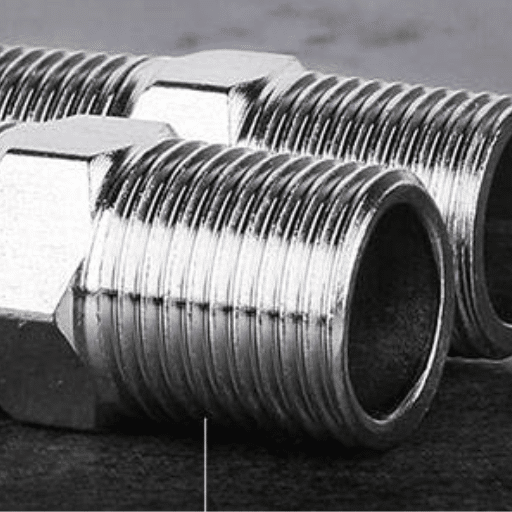

A close nipple has very little threading at each end and is mainly used for connections that are tight and where space is at a premium.

Suitable for plumbing systems and industrial setups that are cramped.

This type has a hexagon shape in the middle which makes it easy to tighten with a wrench.

Commonly used where strong connections in the pipelines are formed, particularly with frequent adjustments.

A long nipple is characterized by its long size, enabling it to connect pipes that are farther apart.

Construction and industrial piping systems that need more flexibility in their layout often use it.

Pipe with different diameters can be connected with this type as it has a different-sized threading on both ends.

Both the residential and commercial systems that have varying pipe diameters in them will benefit the most from their use.

Barrel nipples are of equal threading on both ends and have a constant diameter throughout.

General-purpose pipelines and fluid transfer systems are the fields of its frequent use.

It is clear that each type of stainless steel nipple is indispensable for making connections in different systems that are of high durability, security, and efficiency. Which specific type to go for depends on the individual characteristics and conditions of the application.

Applications of Stainless Steel Nipples in Various Industries

Stainless steel nipples are the components that can be found in almost every industry due to their characteristics such as durability, corrosion resistance, and capacity to deal with high-pressure and high-temperature conditions. The following are the five major industries where the utilization of stainless-steel nipples is significant:

Oil and Gas Industry

Details: Stainless steel nipples are indispensable in the core of pipeline construction and oil, gas, and petroleum products transferring systems. Their innate ability to resist corrosion will, thus, lead to a performance living even in harsh and extreme environments, such as deep-sea drilling or refineries.

Data: They are a part of systems dealing with fluids under pressures of up to 5,000 psi and at temperatures of about 500°F without any problem.

Chemical Processing

Details: The chemical industry is dependent on metals like stainless steel for their reactors, heat exchangers, and piping to handle corrosive chemicals and aggressive solutions.

Data: These components can accept pH levels between very acidic (pH 1) and very alkaline (pH 14) and thus, guaranteeing reliable connections even in extreme conditions.

Water Treatment and Distribution

Details: Stainless steel nipples have an important part to play in water treatment and municipal water distribution by providing hygienic and durable connections.

Data: Their application helps in the prevention of contamination while allowing a maximum pressure of 300 psi in potable water supply systems.

Food and Beverage Industry

Details: Stainless steel nipples are extensively utilized in pasteurizers, brew kettles, and processing lines owing to their compliance with hygiene regulations.

Data: The smooth, non-corroding surfaces of the materials used in manufacture meet FDA standards, thus ensuring food-grade quality in operations involving high temperature or cleaning cycles.

Pharmaceutical and Biotechnology

Details: The pharmaceutical and biotech industries are the ones that would use stainless steel nipples to achieve sterile and contamination-free systems in drug manufacturing and laboratory settings.

Data: They are designed to endure autoclaving and CIP (clean-in-place) processes, thus, complying with very stringent sanitary regulations such as ASME-BPE standards.

The applications mentioned above reflect the significant part stainless steel nipples play in providing and maintaining the safety, efficiency, and durability of industrial systems.

Choosing the Right Pipe Nipple Manufacturer

The selection of an appropriate pipe nipple manufacturer is of paramount importance for the supply of quality products that conform to the required industry standards and support the operation of the whole system. Here are the main points and particulars you should consider while deciding on your manufacturer:

Compliance with Industry Standards

One of the first steps in the search for a reliable pipemaker is to check out their compliance with the aforementioned industry standards ASME-BPE, ISO 9001, and ASTM since these will guarantee the product’s reliability and the product’s lifespan along with good affinity to the strict sanitary and industrial regulations.

Material Quality

The supplier is to source premium quality stainless steel like 304 or 316, to give the product characteristics like rust-proof, long-lasting, and suitable for processing in different areas like the chemical section or clean room ventilation.

Customization Options

Not every manufacturer has customization possibility, but numerous trustworthy companies do offer modification in sizes, types of threads, and aesthetics to give a perfect fit for the respective operating and construction needs.

Manufacturing Processes and Technology

The use of cutting-edge technology in manufacturing, such as CNC machining and automated quality control, assures the detection of the highest degree of precision and uniformity in the products.

Customer Support and Warranty

The manufacturer that you can trust will provide you with the best support and service, including taking care of the timely delivery of products and customer warranties that include coverage for defects in manufacturing or product problems.

In the end, companies will be confident that, by considering these factors across the potential manufacturers, they will choose a trustworthy ally for their pipeline and system needs.

Factors to Consider When Selecting a Manufacturer

A thorough evaluation of different factors is necessary to pick a manufacturer with whom one would be able to establish a successful and reliable partnership. Considering the following five factors in detail is one of the best practices.

Production Capabilities

Evaluate the manufacturer’s ability to produce the necessary amount of product. This includes examining their output scale, the type of technology and equipment used, and their capability to manage custom design or large quantity orders. The products made by manufacturers that have modern production facilities are often very precise and equal in quality.

Standard of Quality Assurance

Be sure that the manufacturer is applying strict quality control standards. Check whether they have certificates such as ISO 9001, and ask what their inspection and testing methods are. The data collected during these processes may help you to draw conclusions about their ability to deliver trustworthy products consistently.

Experience and Expertise

The manufacturer’s experience in the industry would be one of the major factors which would decide the quality of their products and services. Find out what kinds of projects they have worked on in the past, who their clients have been, and what their specialties are. Manufacturers who have through knowledge in your sector are more likely to grasp your needs and challenges.

Supply Chain and Materials Sourcing

Examine the entire supply chain of the manufacturer, where they pick their raw materials from and their standing with the suppliers. Quality of sourcing is dependable and it gives a steady product quality while also minimizing the chances of delays. Manufacturers who are committed to eco-friendly practices may be more attractive to companies who are also committed to being environmentally responsible.

Cost and Value Proposition

Think about the product prices along with the value provided. This is the trade-off between price, quality, time, and also the support after the sale. Prioritizing cost with a thorough breakdown of costs and comparison with other manufacturers can help make sure that you are making a decision that is economically sound without compromising on quality.

Importance of Quality in Pipe Nipples

The durability, performance, and safety of piping systems are heavily reliant on the quality of pipe nipples. Pipe nipples of superior quality not only mitigate the risks of leaks and failures but also enhance the overall efficiency of the system. Here are the five main reasons why quality is important in pipe nipples:

Corrosion Resistance

Excellent quality pipe nipples are usually constructed with corrosion-resistant materials, so they will last a long time and be dependable especially in tough conditions or when used together with corrosive substances.

Pressure Handling Capacity

Top-grade pipe nipples are made to endure high pressures thus the possibility of bursting or deformation due to the operational stress is drastically reduced. This is the reason why they are perfectly suited for industrial applications where robust performance is required.

Accurate Dimensions and Threading

The accuracy in manufacturing guarantees just the right amount of threading and size accuracy, which is a must for a safe and leak-proof connection. Badly made pipe nipples will cause misalignments and thus the system will not work efficiently.

Compliance with Industry Standards

The best pipe nipples satisfy or even go above the international standards like ASTM or ISO thus ensuring regular performance and compatibility with other system parts.

Reduced Maintenance Costs

Using quality pipe nipples is a way of reducing long-term costs for maintenance, repair, and replacement. Their long life span lowers the number of times the system is shut down for maintenance which means saving money and resources.

Domestic vs. International Manufacturers

Concise Answer: Domestic manufacturing offers better communication, faster shipping, and higher quality standards, while international manufacturing provides lower costs and higher production capacity.

Comparison Table

|

Key Point |

Domestic |

International |

|---|---|---|

|

Cost |

Higher |

Lower |

|

Production Capacity |

Limited |

High |

|

Shipping Time |

Faster |

Slower |

|

Shipping Cost |

Lower |

Higher |

|

Quality Standards |

Higher |

Variable |

|

Communication |

Easier |

Challenging |

|

IP Protection |

Stronger |

Weaker |

|

Labor Standards |

Higher |

Lower |

|

Customization |

Easier |

More challenging |

|

Public Perception |

Positive |

Mixed |

Types of Materials Used in Pipe Nipples

Pipe nipples are made of various materials depending on their use and the conditions of the environment where they are going to be installed. The material selection right away determines the life, strength, and compatibility of the pipe nipple. The list of the five materials is given below:

Carbon Steel

Its strength and durability are the reasons why carbon steel is used in high-pressure applications. The wear resistance and low cost make it a favorite in such industries as oil and gas.

Stainless Steel

Stainless steel is not only very corrosion-resistant but also very suitable for use in chemical processing, food and beverage, and other areas where hygiene and anti-rust properties are vital.

Brass

Malleability and corrosion resistance are two of the main reasons why brass is so popular. The material is often found in plumbing and fittings for low to medium-pressure applications.

PVC (Polyvinyl Chloride)

PVC is a plastic that is light, inexpensive, and resistant to both chemical erosion and UV rays. That’s why it’s a perfect material for residential water systems and above-ground plumbing applications.

Copper

Copper is a metal that is sought after mainly for its thermal conductivity and resistance to corrosion. For their dependability and durability, copper pipe nipples are often found in heating, cooling, and drinking water systems.

Stainless Steel vs. Brass Pipe Nipples

Concise Answer: Stainless steel pipe nipples excel in corrosion resistance, strength, and durability, while brass pipe nipples are more cost-effective, easier to install, and suitable for moderate conditions.

Comparison Table

|

Key Point |

Stainless Steel |

Brass |

|---|---|---|

|

Corrosion Resistance |

High |

Moderate |

|

Strength |

High |

Moderate |

|

Durability |

Long-lasting |

Moderate |

|

Cost |

Higher |

Lower |

|

Ease of Installation |

Challenging |

Easier |

|

Pressure Handling |

High |

Moderate |

|

Temperature Range |

Wider |

Narrower |

|

Aesthetic Appeal |

Sleek, modern |

Warm, golden hue |

|

Applications |

Industrial, harsh environments |

Plumbing, decorative |

|

Maintenance |

Low |

Moderate |

Advantages of Using Aluminum Pipe Nipples

Lightweight

Aluminum pipe nipples are among the lightest in the category of pipes. They are, therefore, easy to handle and suitable for applications where weight reduction is very important.

Corrosion Resistance

The use of aluminum in pipe nipples gives excellent resistance to corrosion and particularly in wet and treated environments, that could last as long as the pipes themselves.

High Strength-to-Weight Ratio

Even though the weight of aluminum pipe nipples is quite low, they still possess very high strength, which is the reason why they are widely used for many industrial and structural applications.

Temperature Resistance

Aluminum is the king of temperature resistance since it can co-exist with any of the other materials that are not spoiled with heat or cold.

Eco-Friendliness

The choice of aluminum for pipe nipples is not only sustainable but also very earth-friendly since the material is entirely recyclable.

Understanding Galvanized vs. Non-Galvanized Nipples

Concise Answer: Galvanized nipples are zinc-coated for corrosion resistance and durability, while non-galvanized nipples lack this coating and are more prone to rust but suitable for specific applications like gas transport.

Comparison Table

|

Key Point |

Galvanized Nipples |

Non-Galvanized Nipples |

|---|---|---|

|

Coating |

Zinc-coated |

No coating |

|

Corrosion Resistance |

High |

Low |

|

Durability |

Long-lasting |

Moderate |

|

Cost |

Higher |

Lower |

|

Applications |

Water, outdoor use |

Gas, high heat |

|

Appearance |

Silver-gray |

Dark (black oxide) |

|

Maintenance |

Low |

Moderate |

|

Pressure Handling |

Moderate |

High |

|

Environmental Suitability |

Outdoor, moist areas |

Indoor, dry areas |

|

Lifespan |

50-100 years |

Shorter lifespan |

Product Specifications and Options

Our pipe nipples are characterized by specifications and data that are very thoroughly supplied and the features that are varied for different uses.

Material Choices

Aluminum

Galvanized Steel

Stainless Steel

Black Iron

Brass

Size Options

Lengths from 2 inches to a maximum of 12 inches.

Diameters from 1/4 inch to a maximum of 4 inches.

Threading

NPT (National Pipe Thread) standard threading is used.

Custom threading can be done on demand.

Pressure Ratings

Regular models are rated for 150 PSI maximum pressure.

Models that withstand pressures of up to 300 PSI are offered.

Coating and Finishes

A finish that resists rust and is galvanized.

A finish that is polished for stainless steel variants.

A black-oxide coating provides protection against corrosion.

All these options allow for changes without compromising on quality and reliability, thus making it suitable for all applications.

Standard Sizes and Lengths of Stainless Steel Pipe Nipples

Stainless steel pipe nipples are usually sold in the standard dimensions and lengths given below. The offered sizes cover a broad spectrum of usage, which means they can be quite helpful and easily compatible:

1/8″ x 2″

Diameter: 1/8 inch

Length: 2 inches

1/4″ x 4″

Diameter: 1/4 inch

Length: 4 inches

3/8″ x 6″

Diameter: 3/8 inch

Length: 6 inches

1/2″ x 8″

Diameter: 1/2 inch

Length: 8 inches

3/4″ x 12″

Diameter: 3/4 inch

Length: 12 inches

Apart from these sizes, there are also many other custom sizes available upon request. So can you tell me which one you would like?

Understanding Schedule 40 and Schedule 80 Nipples

Nipples of Schedule 40 and Schedule 80 are distinct mostly due to their wall thickness, pressure rating, and usage. The Schedule 40 nipples come with thinner walls and find their application in the domain of low-pressure pipes whereas the Schedule 80 nipples are thicker, stronger and made for high-pressure and industrial process areas. Both these kinds are available in a wide range of sizes and materials which imparts them versatility for plumbing and mechanical needs in general.

Key Details:

Schedule 40:

Thinner wall for standard applications.

Suitable for low-pressure systems.

Lightweight and economical.

Schedule 80:

Thicker wall for higher pressure demands.

Better durability under stress.

Often used in industrial environments.

Commonly Used Sizes:

1/4″ x 2″ (Schedule 40)

Diameter: 1/4 inch

Length: 2 inches

1/2″ x 4″ (Schedule 80)

Diameter: 1/2 inch

Length: 4 inches

3/4″ x 6″ (Schedule 40)

Diameter: 3/4 inch

Length: 6 inches

1″ x 6″ (Schedule 80)

Diameter: 1 inch

Length: 6 inches

1-1/2″ x 8″ (Schedule 40)

Diameter: 1-1/2 inches

Length: 8 inches.

For more specific applications, custom sizes and materials can often be accommodated upon request, ensuring the right fit for every project.

Custom Options Available from Manufacturers

Manufacturers frequently offer a selection of custom options that together can address all the diverse requirements of specific projects. The availability of the different customizations guarantees the performance, maintenance and the use of different applications. The following are the five most significant custom options that have been announced:

Material Selection

The options comprise PVC, CPVC, stainless steel, and HDPE.

The specifications are different for the various environment and chemical exposures.

Custom Lengths

The pipes can be produced according to the required lengths.

This is very convenient for the projects which have certain spatial limits.

Diameter Variations

Custom diameters are provided to accommodate non-standard fittings.

This is common in the case of specialized industrial or commercial applications.

Wall Thickness Adjustments

Different schedule ratings are included among the offerings (e.g., Schedule 10, 20, 80).

The ratings are based on the pressure and structural demands.

Specialized Coatings or Linings

The finish that is resistant to corrosion and abrasion can be used.

It will be a very good aid in prolonging the life of the equipment in very extreme conditions.

Indeed, these customizations reduce the impact of inflexibility and reliability while thus being able to easily embrace the exact project specification of the products.

Quality Assurance and Standards

Keeping to the highest quality standards is the main factor in establishing the reliability of the product and customer satisfaction. Our products and processes not only meet the industry standards but also go beyond them, thereby evidencing our commitment to being the best.

ISO 9001 Certification

Puts in place a strong quality management system.

assures product quality will be the same every time and there will be continuous improvement.

ASME Compliance

Following the standards set by the American Society of Mechanical Engineers.

Products are guaranteed to conform to the highest requirements of safety and performance.

API Standards

Following the limits set by the American Petroleum Institute.

It is significant for the applications in the field of oil and gas.

Pressure Testing Validation

All products go through a tough pressure test.

It helps to prove the strength of the product under the most extreme operating conditions.

Material Traceability

Production materials are fully documented.

This helps to build trust and makes sure that no one is responsible for any wrongful acts in the supply chain.

These standards and certifications are a testament to our leadership in the industry and our commitment to providing high-quality and reliable products.

Quality Control Measures for Pipe Fittings

In order to offer our customers the pipe fittings with the utmost quality and reliability, we adopt the following main quality control measures:

Dimensional Accuracy Testing

Every fitting is measured against the exact dimensional specifications.

Makes sure that it can be used and joined smoothly in the piping systems.

Non-Destructive Examination (NDE)

Ultrasonic testing and radiographic inspection are the methods used.

Identifies internal defects without changing the fittings’ integrity.

Hydrostatic Pressure Testing

Fittings are placed under very high water pressure conditions.

The strength and leak-proof performance are tested during operational stress.

Chemical Composition Analysis

The analysis done in the laboratory certifies the material to be up to industry standard.

It also helps to mitigate the risk of corrosion and thus ensures long-term durability.

Visual Inspection

It is performed at every stage of production to eliminate surface defects.

It catches the abnormalities such as cracks, dents, or uneven finishes early on.

All of these, together, make sure the quality, safety, and reliability of our pipe fittings, thus making them suitable for a wide range of applications with unmatched performance.

Industry Standards for Stainless Steel Nipples

The stainless steel nipples are subject to a number of industry standards that are to ensure they are of the right quality, safe and perform up to the required benchmarks. By the following five standards, the industry is standardized;

ASTM A312

Covers pipes made of seamless and welded austenitic stainless steel which can be used in high-temperature and corrosive environments.

ASTM A403

Indicates the standard for wrought austenitic stainless steel fittings used in pressure piping systems.

ASME B16.11

Deals with forged fittings, especially socket-welding and threaded fittings, which are used for high-pressure application.

ISO 4144

Gives the international standard for stainless steel fittings and especially points out their resistance to corrosion and their performance.

ANSI B1.20. 1

The standard for pipe threads is explained and particularly in the area of assuring threading compatibility and leak prevention under pressure, it plays a very important role.

These standards are stringent with regard to design, material, manufacture and testing processes and thus guarantee full performance in a wide range of industrial uses.

How to Verify the Quality of Your Pipe Nipples

The quality control of pipe nipples plays a pivotal role in the preservation of the integrity and longevity of your industrial applications. Quality control can be set by the subsequent five cardinal factors:

Material Composition

Check that the quality of the pipe nipples is up to the mark and the metal used is either stainless steel or brass as per the application in question. Get certifications that ratify the material grade and are compliant with the industry standards like ASTM or ISO.

Thread Accuracy

Look at the threads closely to certify that they comply with specifications such as ANSI B1.20 1. Precise threading is a must to achieve fitting compatibility and avoid leaks during operational pressure.

Corrosion Resistance

Consider the pipe nipples’ corrosion resistance first, then for moisture, chemicals, or high/low-temperature environments, the situation will move on. Stainless steel is normally the first choice due to its anti-corrosion properties.

Pressure and Temperature Ratings

Confirm the maximum pressure and temperature at which the pipe nipples are rated and check that those align with your system. Ratings should be clear and compliant with the respective safety standards.

Dimensional Accuracy

Take the measurements of the nipples—length, diameter, and wall thickness—so as to be sure that they have conformed to the stated tolerances. Correct dimensions are of utmost importance for the hassle-free integration with the other components of the system.

Careful and detailed checking of these factors means a long-lasting performance, a minimized risk of system failures and a better overall operational efficiency.

References

- Northwest Health Journal:

Title: Bottle/nipple systems

Description: Discusses methods for evaluating the benefits of various nipple systems, including manufacturing considerations. - Wiley Online Library:

Title: Modeling the physiological factors that affect drug delivery from a nipple shield delivery system to breastfeeding infants

Description: Explores the use of stainless steel components in nipple systems for drug delivery, highlighting manufacturing and design aspects. - LWW Journals:

Title: Know the flow: Milk flow rates from bottle nipples used in the hospital and after discharge

Description: Examines variability in nipple manufacturing and flow rates, providing insights into product consistency and quality.

Frequently Asked Questions (FAQ)

What is a stainless steel nipple and its applications?

A stainless steel nipple is a short piece of pipe that is used to connect two other fittings or pipes in various applications. They are widely used in plumbing, gas, and industrial applications due to their durability and resistance to corrosion. Depending on the requirement, they can be manufactured in different grades such as 304 and 316, providing options for various pressure and temperature conditions.

How are stainless steel nipples manufactured?

Stainless steel nipples are manufactured through processes that include cutting, threading, and welding. The seamless pipe nipples are created from a solid piece of stainless steel, which ensures a strong and reliable connection. Manufacturers adhere to industry standards such as ASTM and ISO to ensure quality and safety in their product offerings.

What are the different grades of stainless steel nipples?

The most common grades of stainless steel nipples are 304 and 316. Grade 304 is ideal for general use, while 316 offers better corrosion resistance, especially in harsh environments. The choice of grade depends on the specific application and the environmental conditions the nipples will be exposed to.

What sizes and diameters are available for stainless steel nipples?

Stainless steel nipples are available in various sizes and diameters to meet customer requirements. Common diameters range from small to large, depending on the application. Custom sizes can also be manufactured upon request to accommodate specific installation needs.

What is a close nipple and when is it used?

A close nipple is a type of pipe nipple that is short in length and has threads on both ends. It is commonly used when a minimal space is required for connection between two fittings or pipes. Close nipples are ideal for high-pressure applications where length needs to be minimized to ensure a secure connection.

How do I ensure quality when purchasing stainless steel pipe nipples?

To ensure quality when purchasing stainless steel pipe nipples, it is essential to choose a reputable manufacturer or distributor. Look for products that comply with industry standards and certifications. Additionally, checking reviews and asking for samples can help verify the quality of the pipe products before making a bulk purchase.

What is the difference between welded and seamless stainless steel nipples?

The primary difference between welded and seamless stainless steel nipples lies in their manufacturing process. Welded nipples are made by joining two pieces of pipe together, while seamless nipples are produced from a single piece of material. Seamless nipples generally provide better strength and are preferred for high-pressure applications due to their lack of weld seams, which can be potential weak points.

How can I contact a stainless steel nipple manufacturer?

You can contact a stainless steel nipple manufacturer through their official website, where you can find contact information, including phone numbers and email addresses. Many manufacturers also provide online forms for inquiries. If you need specific information about inventory, pricing, or delivery options, reaching out directly will provide the most accurate and up-to-date information.

What are the common applications for stainless steel nipples in industrial settings?

In industrial settings, stainless steel nipples are commonly used in piping systems for transporting gas, oil, or water. They are also utilized in various equipment installations where a reliable and corrosion-resistant connection is required. Their ability to withstand high pressure makes them ideal for critical applications in industries such as petrochemical, food processing, and pharmaceuticals.