The comprehension of the basic standards of steel products is very important in the different areas of construction and manufacturing. The ASTM steel standards are the among these standards that play an important role in such applications by providing the same level of quality and performance. However, the question is what ASTM steel actually is and its importance? The present blog has gone into the depths of the ASTM standard and steel products, highlighting their substance, the different types of steel included, and the ways the standards influence the quality and performance of the materials used worldwide. The article is aimed at professionals in the industry, engineers, and those who are just interested in the science behind the production of stronger and longer-lasting materials. It gives a complete picture of how the ASTM steel standard is worth its weight in gold.

Introduction to ASTM Steel Standards

ASTM steel standards are rules laid out by ASTM International meant to ensure uniformity, quality, and safety in both the manufacture and the use of steel materials. The standards set the requirements for properties like strength, composition, and durability, thus facilitating the manufacturers to make dependable steel products. They are extensively applied in various industries and provide consistency in the construction, engineering, and manufacturing sectors, thus making the steel materials to be of the required performance and safety standard.

What is ASTM?

ASTM, which was previously referred to as the American Society for Testing and Materials, is an international organization that sets up and provides voluntary technical standards for a vast array of materials, products, systems, and services. Established in 1898, ASTM has always been focused on quality and safety through its strict testing and standardization process. Currently, the organization counts about 12,000 standards, which are adopted in different countries, especially in the aforementioned industries, among others. The standards address material specifications, testing procedures, and performance guidelines areas that thus help unify the quality and safety standards across the globe.

Importance of ASTM Standards in the Steel Industry

The steel industry, being heavily dependent on the ASTM standards, is receiving these standards as a continuous support in the form of consistent quality, safety, and reliability of the materials used. These standards are very exhaustive and they cover the main characteristics of the materials like chemical composition, tensile strength, and durability. One example is ASTM A36 which is the most acknowledged standard for carbon structural steel, and therefore it provides a base for uniformity in the construction practices all over the world. The standardization has helped to a large extent in avoiding the risks of structural failures, encouraging worldwide trade, and lighting the fire of innovation in the steel industry. The companies that follow ASTM’s strenuous testing processes can cater to both the local and the global market needs in terms of compliance with the regulations which, in turn, helps to build the trust and the credibility of the company in the sector. The active nature of ASTM standards continues to give steel the first choice for infrastructure, automotive, and other technical applications.

Overview of Steel Products Covered by ASTM

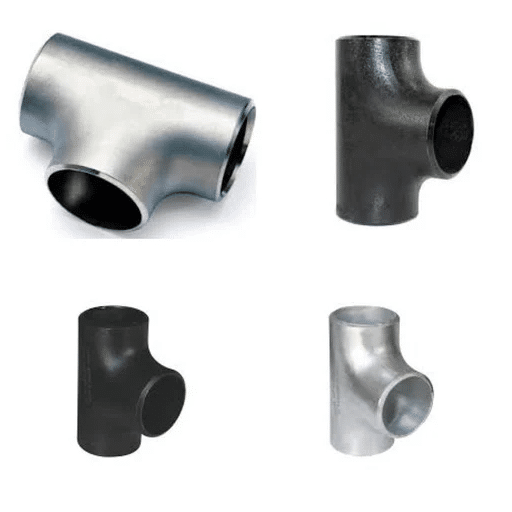

The ASTM standards offer a wide range of steel products that cover various industries and applications. Among them are structural steel for construction, steel for the automotive industry, and special alloys for the aerospace and energy sectors. The ASTM also covers steel pipes, tubes, plates, sheets, wires, and bars, which are all priced for quality, durability, and performance. ASTM A36 steel is a commonly referenced specification for structural purposes, mainly credited for its mechanical properties and weldability. Stainless steels, under standards like ASTM A240, are indispensable in industries where corrosion resistance is a necessity, such as food processing and chemical manufacturing.

Latest statistics reveal that the global reliance on ASTM steel standards is increasing as the demand for sustainable and high-performance materials continues to grow. The automotive industry, for example, is still the biggest user of ASTM-compliant advanced high-strength steels (AHSS) for better fuel saving and crash safety. In the same way, the renewable energy sector uses ASTM-audited steel grades for the construction of wind turbine towers and solar panel supports. This extensive range of coverage emphasizes the significant role that ASTM plays in material standardization, which, on the other hand, helps to foster and maintain innovation and reliability in different sectors.

Types of ASTM Steel

Carbon Steels (ASTM A36, A283): These steels are mostly suitable for all construction and structural applications wherever their strength and low price are acceptable.

Alloy Steels (ASTM A514, A572): Alloy steels, which may consist of various metals like chromium, molybdenum, and nickel, are in general the most superior in terms of the three properties of strength, toughness and wear resistance. They are often used in applications that demand a lot from engineering and industrial sectors.

Stainless Steels (ASTM A240, A276): Having the superior feature of corrosion resistance, they find usage in chemical processing, medical devices and food contact equipment. Besides they are considered highly versatile and assorted into grades such as 304 and 316.

Tool Steels (ASTM A681): Tool steels are made for industrial tools and dies and they are quite hard and can resist very high temperatures and impacts making them suitable for cutting and forging operations.

High-Strength Low-Alloy Steels (ASTM A588, A606): These steels offer the combination of good strength and atmospheric corrosion resistance, thus making them suitable for bridges, construction, and railway cars.

Structural Steels (ASTM A992, A500): These materials are mainly used in the construction of buildings and infrastructure, and known for their good quality and predictable performance under load.

Weathering Steels (ASTM A588): These are best steels that after being exposed to the atmosphere for a while develop a protective patina which makes them extremely rust resistant and thus can be used in outdoor structural projects where aesthetics are important.

ASTM Steel Grades Explained

Classes of steel known as ASTM steel grades are the result of the American Society for Testing and Materials (ASTM) which through testing and examination defined the various properties of steel types through their composition and application. These grades form a common platform, allowing it to be thus a

quality- and consistency-assured metal for each industry using it.

There are some important ASTM steel grades:

ASTM A36: The low-carbon steel is the one that mainly is to be used in construction and structural application, and is known for its strength and flexibility and weldability.

ASTM A572: The steel is high-strength and low-alloy one, usually used in bridges and other structural applications where higher strength with less weight would be required and thus, the weight would not need to be increased.

ASTM A992: The steel is widely used in the construction of structural steel members such as beams and columns, mostly because of its good strength-to-weight ratio and weldability.

ASTM A500: The steel is characterized by being used for hollow structural sections (HSS), having strength, formability, and corrosion resistance while being lightweight and cost-effective.

ASTM A588 (Weathering Steel): This distinctive grade of steel has the property of forming a rust-like protective layer when exposed to the weather, thus it is perfect for architectural and outdoor projects because of the extra resistance to corrosion.

ASTM A514: The alloy steel that is quenched and tempered, needing remarkable yield strength and durability such as heavy machinery or building plate steel, is thus an application requiring a steel quality that is not only strong but also works exceptionally well with your equipment.

Common Types of Steel and Their Applications

Carbon Steel

Carbon steel is among the most popular types of steel, and it is classified into low, medium, and high-carbon steels. It usually has a maximum of 2% carbon and traces of other elements. Due to its low price and wide range of use, it finds application in building (for example, beams, reinforcing bars), automotive parts, and kitchen appliances.

Stainless Steel

Stainless steel, which contains a minimum of 10.5% chromium, is resistant to rust, staining, and corrosion. The longevity of the material makes it suitable for use with medical tools, food-grade equipment, and architectural parts. The most common grades are 304 and 316, which are each specifically designed for different settings like marine or sterile applications.

Tool Steel

Tool steel is a type of steel that is made specifically for the purpose of making tools, cutting, and molding. The steel contains the elements tungsten, molybdenum, and vanadium to produce hardness and heat resistance. It is widely used for making drills, cutters, and dies because of its ability to endure high stress and temperatures.

Alloy Steel

The purpose of alloy steel is to combine elements such as manganese, nickel, or titanium in order to provide better mechanical properties. Its application ranges from pipelines, through car parts, to machinery—the areas where its enhanced toughness, strength, and wear resistance are really appreciated.

Weathering Steel (Corten Steel)

Corten steel, another name for weathering steel, slowly gains a layer of protective oxide that thereby stops further corrosion to happen. The material is chosen for use in the construction of bridges, sculptures, and building facades, being strong and providing a rustic look with low maintenance. It is a favorite for outdoor works as it can withstand and even flourish in different weather while being sturdy enough to last.

Alloy vs. Carbon Steel: ASTM Classifications

|

Key Point |

Alloy Steel |

Carbon Steel |

|---|---|---|

|

Composition |

Carbon + alloys |

Mainly carbon |

|

Strength |

Higher |

Moderate |

|

Ductility |

Higher |

Lower |

|

Corrosion Resist. |

Better |

Lower |

|

ASTM Examples |

A335, A213 |

A36, A106 |

|

Applications |

Tools, machinery |

Construction, pipelines |

|

Cost |

Higher |

Lower |

Material Properties of ASTM Steel

1. Tensile Strength

The term tensile strength signifies the heaviest stress that a certain material will support when it is stretched or pulled, and the material will not break. The widely utilized carbon steel ASTM A36 has a tensile strength of 400-550 MPa, while the tensile strength of the alloy steel ASTM A335 varies significantly, particularly depending on the grade, and very often goes beyond 500 MPa. Consequently, alloy steels are the choice in fields where superior strength is required.

2. Yield Strength

Yield strength is the point at which steel starts to undergo permanent deformation under stress. Generally, the yield stress of carbon steels like ASTM A36 is estimated to be about 250 MPa, whereas that of high-performance alloy steels such as ASTM A213 grades is usually much stronger, sometimes even above 300 MPa. This is the reason why alloy steel is regarded as suitable for heavy-duty applications.

3. Hardness

The hardness of ASTM steels, which is usually expressed in Brinell (HB) or Rockwell (HR) scales, is different for different grades of steel. For example, the hardness of ASTM A106 carbon steel pipes usually varies between 120-160 HB depending on the heat treatment process and quality of steel. However, alloy steels such as ASTM A335 are usually hard enough to be compared with them and providing they have the same hardness level they will have the property of being more resistant to wear.

4. Corrosion Resistance

Resistance to corrosion is a major property, especially in industries where harsh environments are present. Alloy steels containing chromium, molybdenum, or nickel, such as ASTM A213, are very much corrosion-resistant compared to the carbon steels A106 or A36. It can, therefore, be concluded that alloy steels are more suitable for the applications involving the oil, gas, or chemical industries by being more durable.

5. Ductility

Ductility is the property of steel to be stretched under tensile stress without fracturing. With the unique composition of alloy steel, the ductility of these materials is higher which eventually results in greater flexibility during processing. For instance, ASTM A213 alloy steel tubing meets mechanical application requirements of both strength and ductility.

6. Thermal Conductivity

Alloy steel generally has lower thermal conductivity than carbon steel. ASTM A106 carbon steel has thermal conductivity of about 50 W/m·K which is good for using in heat exchangers and boilers among other applications. Nevertheless, the reduced thermal conductivity in alloy steel, such as ASTM A335, is generally offset by its better strength and heat resistance under very harsh conditions.

7. Cost-Efficiency vs. Performance

One might say that alloy steels are more costly due to their composition, but they often deliver better performance in the long run as the need for frequent replacements or repairs is thus reduced. On the other hand, carbon steels are the most economical base-metal and hence their use is very extensive in the projects where cost considerations prevail.

Mechanical Properties of ASTM Steel

Tensile Strength

The tensile strength of a material is the measure of its maximum stress that it can tack on when it is stretched or pulled until the failure happens. For instance, the ASTM A36 structural steel grade has a minimum tensile strength of 58,000 to 80,000 psi (400 to 550 MPa), but this depends on the size and thickness of the steel.

Yield Strength

Yield strength is the stress at which a material begins to undergo plastic deformation. The minimum yield strength for ASTM A572 Grade 50 is 50,000 psi (345 MPa), which makes the metal suitable for use in high-strength, low-alloy structural parts.

Elongation

Elongation is a measure of the steel’s ductility and is given as a % increase of its length before fracture. ASTM A36 steel elongates at a minimum rate of 20% for plates over 3/4 inch thick, thus providing flexibility for the construction industry.

Hardness

Hardness is the measure of the ability of the steel to withstand the effects of pressure or to receive a dent. A514, a quenched and tempered highly yielded alloy steel, has an average Brinell Hardness Number (BHN) of 235–293 which enables the steel to be used in applications needing wear resistance.

Impact Resistance

Some ASTM steels, including A516 Grade 70, are tested for impact resistance in low-temperature conditions. This grade of steel exhibits very high toughness; Charpy V-notch impact tests on it are frequently in excess of 20 ft-lbs at -20°F.

Fatigue Strength

The fatigue resistance is of utmost importance to the cyclic loading and its components. The ASTM A500 structural tubing is extensively used in this area, as it provides the vanquishing fatigue strength that comes from its uniformity and mechanical composition.

Summary Table of Common ASTM Steel Grades

|

Steel Grade |

Tensile Strength (psi) |

Yield Strength (psi) |

Elongation (%) |

Applications |

|---|---|---|---|---|

|

ASTM A36 |

58,000 – 80,000 |

36,000 |

20 – 23 |

Structural components, bridges |

|

ASTM A572 Grade 50 |

65,000 |

50,000 |

18 – 21 |

High-strength, low-alloy structures |

|

ASTM A514 |

110,000 – 130,000 |

100,000 |

16 – 18 |

Heavy equipment, wear plates |

|

ASTM A516 Grade 70 |

70,000 – 90,000 |

38,000 |

21 – 23 |

Pressure vessels, boilers |

|

ASTM A500 |

45,000 – 58,000 |

39,000 |

23 – 25 |

Tubular structures, columns |

Chemical Composition and Its Importance

The chemical composition of steel is very important to its mechanical properties, functionalities, and applications. Steel consists mainly of iron and carbon but the addition of manganese, chromium, nickel, molybdenum, and vanadium in certain amounts improves the steel’s properties such as strength, ductility, and wear and corrosion resistance. Every grade of steel is made up of a specific chemical mixture which is the best for its intended purpose. For example, ASTM A36 consists of a well-balanced mixture of carbon and manganese so as to give it flexibility and weldability, while ASTM A514 contains a higher percentage of chromium and molybdenum so as to have increased hardness and abrasion resistance.

Such accurate regulation of chemical content is essential for compliance with industry regulations, as well as for the safety and reliability of the product. High-strength low-alloy steels like ASTM A572 Grade 50 are made to be efficient in terms of structure, whereas pressure vessel steels like ASTM A516 Grade 70 are made with a focus on their ability to withstand heat and pressure. It is the knowledge of the complex interplay between chemical composition and mechanical properties that helps an engineer or designer to select the right steel for a particular project, thus reducing risks and increasing efficiency.

How to Read ASTM Material Specifications

Reading ASTM material specifications demands one’s full attention and a clear understanding of the standard’s layout. ASTM specifications are made up of the designation (for example, ASTM A572), the grade, and the list of properties. The designation denotes the type of material, like structural steel, pressure vessel steel, or stainless steel. The grade reveals the material’s strength or other distinguishing aspects, and the rest of the notes give details about chemical composition, mechanical properties, and test methods.

After identifying the material designation and comparing it with the corresponding ASTM standards summary, start the assessment of the mechanical properties usually given in numerical tables. The chemical composition section indicates the material’s elemental limits, such as the maximum allowed percentages of carbon, manganese or sulfur, which are important for the performance of the material. Finally, make sure that any additional requirements or notes in the standard, such as heat treatments or testing methods, are compatible with your project by reviewing them.

A systematic approach combined with easily accessible resources like Google’s search engine enables engineers and designers to gain additional access to resources including cross-references, application areas, and guides on specific material grades. This not only broadens the understanding but also secures choosing the most appropriate material for the specified application.

Specific Applications of ASTM Steel

ASTM steel is the best choice in many industries because of its good nature, strong survival power, and being in line with the global regulations. As an example, ASTM A36 steel, a standard structural steel, is extensively used in the building construction for structural support, bridges, and general metalwork. And in the other hand, ASTM A516 steel is very suitable for the production of pressure vessels and boilers where the metal is required to have a quality of of holding high pressures and temperatures extraordinarily.

The latest search engine data from Google shows that the ASTM stainless steels like ASTM A240 are the materials with the highest performance that are most wanted in the industries of food processing and chemicals. They resist corrosion and they are able to perform well in difficult and harsh places. Besides that, the ASTM grades such as A572 known for their high strength and low alloy composition are being applied in the infrastructure projects like bridges for highways, towers for power transmission and heavy equipment.

In fact, the wide range of applications of ASTM steels is the main reason they have become a staple in the me modern and technological engineered world. The combination of easily accessible information resources and advancements in material science enables the professionals to decide on the most appropriate materials for their unique use cases.

Use of ASTM Steel in Construction

ASTM steel is an essential material in the construction industry owing to its long life, wide application, and confominance to standard quality the requirements. These grades of steel are the main construction materials in the tall buildings, bridges, and factories where the strength and safety of the structure are the main concerns. Their reliable performance under different environmental conditions makes them a trustworthy option.

Using the most recent information from Google’s search engine, it is obvious that the ASTM steel standards are still the major factors for engineers to consider when it comes to choosing the right materials for the specific mechanical and chemical properties of the building. For instance, ASTM A992, a commonly used structural steel grade, is chosen for I-beams of high-rise buildings because of its perfect combination of strength and flexibility. Recent technical enhancements and resouces facilitate the builder’s ability to include the ASTM-certified steel in the cutting-edge design while still being compliant with the safety codes, thus highlighting its vital role in the present construction methods.

Pressure Vessel Applications

Chemical Processing

The chemical industry has made extensive use of pressure vessels for storing and processing chemicals at controlled temperatures and pressures. For example, reactors and distillation columns are highly dependent on pressure vessels for efficient operation in a high-stress environment.

Oil and Gas Storage

Pressure vessels are the backbone of the crude oil, natural gas, and other petrochemical products storage and transportation system. Their strong construction not only avoids leaks but also guarantees safe containment even in the most extreme conditions.

Power Generation

In power plants, pressure vessels are utilized for both boilers and steam drums. They generate and store steam which is then used to drive turbines for electricity generation. This process is highly efficient.

Food and Beverage Industry

One of the main applications of pressure vessels is for carbonation, pasteurization, and sterilization, which are processes that all maintain product quality but also adhere to strict industry standards.

Pharmaceutical Manufacturing

The sterile conditions and accurate temperature regulation made possible by pressure vessels are among the most important factors that determine the quality of pharmaceutical products.

ASTM Steel in Manufacturing and Industrial Uses

ASTM steel owes its exceptional durability, versatility, and adherence to the highest quality requirements to being able to cater to a wide range of manufacturing and industrial applications. ASTM, which stands for the American Society for Testing and Materials, has set the bar for steel production to be exact, thus guaranteeing performance and reliability across the board. From the construction of vehicles to the energy sector, and from heavy machinery to the likes of the latter, ASTM steel is the very thing that delivers the desired combination of strength and resilience to be able to go through the hardest of times.

The most current statistics indicate that over-the-counter quality steel is at its highest demand in green energy sectors like windmills and photo-voltaic energy plants not only because of its stress resistance but also for helping to meet sustainability targets. Plus, its continuous use in tech-forward industries like 3D printing, shows its capacity to fit into the modern manufacturing process quite well. Thus, the combination of conventional strength and the power to innovate just underlines that ASTM steel is still going to be a significant player in the future of industrial and manufacturing advancements.

Conclusion: The Role of ASTM in Steel Standards

ASTM International has an extremely important function in not only laying down the standards for the various qualities of steel, but also the safety and reliability of the steel in different industries. The standards set forth laid down by ASTM are the driving force behind the manufacturers and innovators being consistent as the materials that are used in the construction, infrastructure, automotive, and even high-tech industries are all meeting the demanding standards of the various fields. According to recent statistics, the importance of ASTM in setting the standards for steel is still very high as manufacturers across the board are still trying to find ways to incorporate long-lasting and eco-friendly materials into their products and processes. The compliance with ASTM standards has the effect of not only ensuring consistency(purity), but also establishing global ties, hence making it possible for the movement and production of goods to cross borders effectively. With the coming of new challenges and technologies, ASTM consistently adapts its standards to cope with the modern world’s changing needs thus, firmly placing itself as a mainstay in the steel industry.

Future Trends in ASTM Standards

It is very likely that the future of ASTM standards will be in line with technology that is developing very rapidly and the demand for sustainability and innovation in different sectors that is growing ever more. One of the major trends is the use of AI and machine learning tools as an integral part of the testing, analysis, and compliance processes. AI-driven predictive modeling is helping industries to achieve higher material performance and at the same time, cut down on the wastage of resources. In addition to that, the production of green steel and the overall world movement towards decarbonization are turning ASTM standards into more eco-friendly ones in terms of procedures.

Still, one more significant trend is the spotlight on 3D printing technology (additive manufacturing) by which the steel and materials industries are getting influenced. ASTM is anticipated to introduce more detailed standards that will be determining the quality and consistency of the materials used in this maturing industry. Furthermore, the increasingly global nature of supply chains calls for the alignment of international standards, and thus ASTM is likely to intensify partnerships with organizations across the globe to facilitate the convergence of regulatory frameworks.

The interplay of digital technologies, sustainability initiatives, and the global nature of business operations is indicative of a scenario in which ASTM standards will continue to be the driving force behind innovation, allowing the industries to tackle the contemporary challenges with great efficiency and precision.

How to Stay Updated with ASTM Codes

It is a must for professionals working in the areas of compliance and safety to keep abreast of the ASTM codes. One great way to stay updated is to take advantage of the official ASTM International services like the Compass platform, which offers real-time access to the most recent standards, revisions, and updates. In addition, making use of Google’s search engine can also be a very helpful tool; for instance, you can create Google Alerts for terms like “ASTM standard updates” or specific codes so that you get notified whenever there are relevant changes or new developments. Another way to keep oneself updated about new publications and initiatives is to periodically check the ASTM International website or follow their social media accounts. Besides this, participation in webinars, industry conferences, or ASTM committee meetings is yet another way to get first-hand information from the experts. By utilizing these resources collectively, the professionals will be able to make sure that they are always up to date with the latest ASTM standards and industry practices.

Final Thoughts on Choosing the Right ASTM Steel

In order to select the appropriate ASTM steel, it is necessary to have a clear vision of your project needs first. These project requirements would encompass essential mechanical attributes, longevity, and environmental resistance. It is quite common for the professional world to rely on the broad search power of Google to access the most current specs, uses, and comparisons for various ASTM steel grades easily. It is still advisable to combine this data with information from ASTM resources to ensure that the selected steel complies with both the requirements of and the specifications of the industry. All in all, the use of these tools and being knowledgeable will contribute to the long-term performance, safety, and cost-effectiveness of your project.

References

-

Handbook: Hand Book of Comparative World Steel Standards

A detailed guide comparing ASTM steel standards with global equivalents. -

Academia.edu: Experimental investigation of mechanical properties of ASTM A992 steel at elevated temperatures

An experimental study on the behavior of ASTM A992 steel under high-temperature conditions.

Frequently Asked Questions (FAQ)

What are ASTM Steel Standards?

The specifications of ASTM steel standards describe the characteristics and requirements for different products made of steel. They deal with the whole range of issues from structural quality to certain applications such as pressure vessels and stainless steel pipes, helping materials to fulfil the safety and performance norms.

What types of steel are included in ASTM standards?

Among the ASTM standards one can find a great variety of types of steel like carbon steel, alloy steel, austenitic stainless steel, and duplex alloy steel. One can characterize each type by its special properties that enable it to serve in different applications like structural tubing, pressure vessel plates, and high-temperature service.

How can I access the latest ASTM Steel Standards?

You can find the latest ASTM steel standards on the website of ASTM International or by buying specific codes. This guarantees that you have the most current knowledge about the physical and chemical properties and the specifications for various kinds of steel products.

What is the standard specification for pressure vessel plates?

The standard specification for pressure vessel plates describes the technical conditions for the investment of pressure vessels. The specification then includes the requirements for the mechanical and chemical properties, the types of steels with lower-than-capacity chemical compositions, and the applications of carbon and alloy steel.

What are some common applications of ASTM Steel?

ASTM steel is found in many applications and forms in different industries. The most common uses are in the building and construction business, the manufacture of iron and steel products, automobile parts, and the making of welded and seamless carbon steel pipes for high-temperature service.

Are there different grades of ASTM Steel?

Yes, the various ASTM steel gradings depend on the difference in their chemical composition and physical properties. For instance, ASTM A36 is a common grading that is applied to structural steel, while ASTM A516 is used for pressure vessel plates. Each of the grades is specified for certain applications that are based on the properties of the grade.

What is the significance of ASTM Steel Grades?

The importance of ASTM steel grades lies in providing a uniform procedure for categorizing steel products according to their properties. This aids the manufacturers and engineers to select the most appropriate material for a particular application thus assuring safety and performance in the construction and engineering projects.

What materials are typically found in ASTM Steel Products?

Steel products according to ASTM standards mostly consist of a mix of materials like rolled steel, steel sheets, tempered alloy steel plates, and so on. Moreover, stainless steel products such as austenitic chromium-nickel stainless steel and electric-fusion-welded austenitic stainless steel also fall under the ASTM specifications.