Stainless steel tubing is significant to almost every industry, ranging from aerospace to medical technology, where selecting the appropriate type may weigh much on the performance and longevity. Among the available options stands bright annealed stainless steel tubing for its superior finish, durability, and versatility. But then, what are the exact differences of a seamless tube and why is it chosen in precise applications?

In this comprehensive guide, we’ll explore the attributes of bright annealed stainless steel tubing, mainly focusing on the seamless variety. We’ll cover the differences, benefits, and key considerations to help you determine the best solution for your specific needs. Whether you are building equipment for corrosive environments or want a pristine finish on display, this guide provides all the answers you need.

Introduction to Bright Annealed Tubes

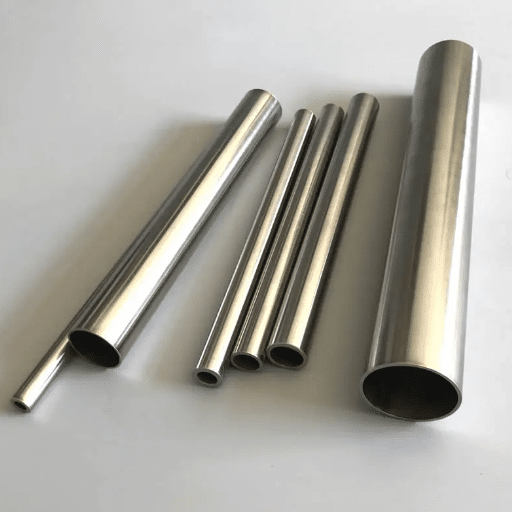

Bright annealed tubes are a specialized category of stainless steel tubes subjected to controlled heat treatment in a vacuum or inert atmosphere. This treatment results in a smooth, reflective finish that makes them highly corrosion resistant and suitable for applications requiring clean and polished appearances.

What Are Bright Annealed Tubes?

Bright annealed tubes are stainless steel tubes that have been heat treated to achieve a polished, reflective finish in a controlled atmosphere such as vacuum or inert gas. The bright annealing process enhances the corrosion resistance of the tubes by improving the chromium oxide layer on the surface, making them ideal for:

- Food processing applications

- Pharmaceutical manufacturing

- Medical technology

- Chemical handling applications requiring cleanliness

These tubes are typically seamless, which enhances their strength, durability, and structural integrity, making them highly desirable for high-pressure or high-temperature environments.

Applications of Bright Annealed Stainless Steel Tubing

| Industry | Application | Key Benefits |

|---|---|---|

| Pharmaceutical | Manufacturing equipment and piping | Sanitary nature, contamination prevention, hygiene compliance |

| Food & Beverage | Liquid transfer, syrups, gas handling | Product purity maintenance, no material leaching |

| Semiconductor | Ultra-pure gas and chemical transport | Smooth surface prevents particulate buildup |

| Automotive | Exhaust systems, fuel lines | High-temperature resistance, mechanical strength |

| Medical Equipment | Sterile devices and equipment | Prevents bacterial growth, ensures patient safety |

Key Characteristics of Bright Annealed Tubes

Bright annealed tubes are characterized by several superior properties obtained through controlled heat treatment processes:

- Superior Surface Finish: Mirror-like polish achieved through non-oxidizing atmosphere treatment

- Enhanced Corrosion Resistance: Improved chromium oxide layer protection

- Excellent Mechanical Strength: Superior durability and flexibility for critical applications

- Dimensional Accuracy: Reliable precision for consistent industrial processes

- Non-porous Surface: Blocks bacteria-causing germs for medical and hygienic applications

- High Wear Resistance: Excellent performance even in extreme environmental conditions

Difference Between Annealed and Bright Annealed Tubes

| Aspect | Standard Annealed Tubes | Bright Annealed Tubes |

|---|---|---|

| Heat Treatment | Standard heating and slow cooling | Controlled cooling in vacuum or inert atmosphere |

| Surface Finish | Dull or matte finish | Bright, mirror-like reflective finish |

| Corrosion Resistance | Standard resistance | Enhanced corrosion resistance |

| Applications | General industrial use | Pharmaceuticals, food processing, medical devices |

| Contamination Risk | Higher risk due to surface texture | Minimal risk due to smooth surface |

Understanding the Annealing Process

The annealing process is a crucial heat treatment comprised of several stages designed to alter the physical and chemical properties of materials. The process involves:

- Heating: Material is heated to a specific temperature

- Holding: Temperature is maintained for a predetermined period

- Cooling: Controlled cooling to achieve desired microstructure

Benefits of Bright Annealing

Bright annealing offers significant advantages for both industrial applications and environmental considerations:

- Surface Integrity: Maintains smooth, clean finish essential for pharmaceutical and food processing

- Reduced Oxidation: Minimizes scaling and improves corrosion resistance

- Extended Material Life: Enhanced durability and longevity

- Environmental Benefits: Aligns with sustainability goals through waste minimization

- Uniform Properties: Consistent mechanical properties for precision engineering

Types of Stainless Steel Tubing

| Type | Manufacturing Process | Key Advantages | Typical Applications |

|---|---|---|---|

| Seamless | No welding process | Superior structural integrity, pressure resistance | Aerospace, nuclear, automotive |

| Welded | Welding steel sheet/strip | More economical, reasonable performance | Decorative, low-pressure applications |

| Polished | Final surface treatment | Visual appeal, cleanliness | Food processing, medical instruments |

| Bright Annealed | Controlled atmosphere heat treatment | High corrosion resistance, uniformity | Chemical processing, pharmaceuticals |

Stainless Steel Grades: A269 vs A270

| Grade | Primary Use | Key Features | Cost Consideration |

|---|---|---|---|

| A269 | General-purpose tubing | Robustness, good corrosion resistance, flexibility | Lower cost, cost-effective |

| A270 | High-purity applications | Superior surface finish, low carbon content, stringent hygiene standards | Higher cost, specialized applications |

Specifications of Bright Annealed Tubing

Materials

Bright annealed tubes are typically manufactured from high-quality stainless steel grades:

- 304 and 316 stainless steel

- Low-carbon variants: 304L and 316L

- Superior resistance to oxidation, chemicals, and high temperatures

Common Sizes and Dimensional Tolerances

| Specification | Range | Tolerance |

|---|---|---|

| Outer Diameter (OD) | 1/16 inch to 4 inches | Strict tolerance requirements |

| Wall Thickness | From 0.010 inches | Precision manufacturing |

| Length | Custom lengths available | Application-specific |

Surface Finish Standards

- Smooth, dense, and reflective surface

- Contaminant-repelling properties

- Easy cleaning capabilities

- Critical for sanitation industries

Quality Standards for Bright Annealed Tubing

To ensure proper performance, safety, and longevity, bright annealed tubes must meet strict quality standards established by international regulatory agencies:

Regulatory Standards

- ASTM Standards: American Society for Testing and Materials

- ISO Standards: International Organization for Standardization

- Regional Requirements: Country-specific regulations

Quality Testing Requirements

| Test Type | Purpose | Standards |

|---|---|---|

| Dimensional Tolerance | Ensure precise measurements | ASTM specifications |

| Chemical Composition | Verify material properties | Grade-specific requirements |

| Surface Finish | Uniform finish without defects | Visual and tactile inspection |

| Hydrostatic Testing | Pressure resistance verification | Industry-specific pressure ratings |

| Eddy Current Testing | Detect structural defects | Non-destructive testing standards |

References

-

Welded Stainless Steel Pressure Pipe from China – U.S. International Trade Commission (USITC)

A report discussing bright annealing processes and their applications in stainless steel tubing.

Visit the site -

Specification for Piping Design / Materials – LIGO (Caltech)

A specification document detailing the use of bright-annealed finishes in piping and tubing for scientific applications.

Visit the site -

Superaustenitic Steel Tubing Specifications – NASA Standards

A NASA specification document discussing bright annealing for corrosion-resistant stainless steel tubing.

Visit the site

Frequently Asked Questions (FAQ)

What makes annealed and bright annealed tubes different?

The major difference between annealed tubes and bright annealed tubes relates mainly to surface finish and treatment. The bright annealing involves an extra step heating and rapid cooling in a controlled atmosphere, which produces a smooth and reflective surface that tends to diminish surface oxidation. This better resists pitting corrosion when compared with the regular annealed tubes, thus making bright annealed tubes more suitable in corrosive environments.

How is the annealing process for bright annealed tubes performed?

The bright annealing of tubes involves a protective atmosphere with reducing gas properties to minimize oxidation. This controlled atmosphere protects the quality of tubes on heating and had thus superior mechanical properties and finish. The usual process involves heating the tube to a certain temperature, keeping the tube at that temperature for a predefined time, after which it is usually cooled quickly.

What materials are bright annealed tubes made of?

Bright annealed tubes are typically made from types of stainless steel, particularly in their seamless form. They can also be made from different alloys, depending on the desired mechanical properties and corrosion resistance. The composition of the alloy is an essential factor in determining how well the tube will perform in various applications, especially in beverage industries where hygiene and durability are key requisites.

What sizes does bright annealed tubing come in?

Bright annealed tubing comes in a multitude of sizes, including those of much smaller diameters. Because of the wide-ranging outer diameters (ODs), they find applications starting from industrial to medical. The exact size generally depends on the final application and required flow characteristics.

What is the performance relationship between surface roughness and bright annealed tubes?

Surface roughness shows a direct influence on the performance of bright annealed tubes, which is even more valid in terms of fluid dynamics and corrosion resistance. A smooth surface results in a lesser chance of crevice corrosion and pitting corrosion, thus allowing these tubes to last long under harsh environments. Therefore, a bright annealed finish aids in keeping the surface clean, which is paramount to food and beverage industries.

Are bright annealed tubes good for high-pressure applications?

Brightness-annealed tubes may be suitable for high-pressure applications, especially when made of stainless steel or common precursor materials that ensure their strength and durability. The seamless tubes can withstand high pressure without risking weld-induced defects. However, distinctions in the properties of the material of construction and exact alloy composition, as well as strength, need to be considered for an application assessment.

How was the A270 specification important in the bright annealed tubes?

The A270 specification is essential to bright annealed tubes since it clarifies the sanitary process tubes used in food and beverage industries. Such a specification ensures that the tubes are extremely clean and resistant to corrosion, mechanically. This specification is very important in assuring hygiene and safety in food and drink processing applications.

Can bright annealed tubes undergo laser welding?

Yes, bright annealed tubes can be laser welded, provided the surface finish and mechanical properties of the tubes are not adversely affected by the welding process. Laser welding is advantageous because it offers precision, flexibility to minimize heat-affected zones, leading to enhanced durability and performance of applications wherein joint integrity is critical.