Premium Bright Annealed Tubing Manufacturer in China

Our Bright Annealed Stainless Steel Tubing, often called BA Tube, undergoes a meticulous bright annealing process. The smooth, oxide-free surface minimizes contamination risks.

Bright Annealed Tubing

- Premium Quality

- Customizable Sizes

- Industrial Grade

Overview :

Description :

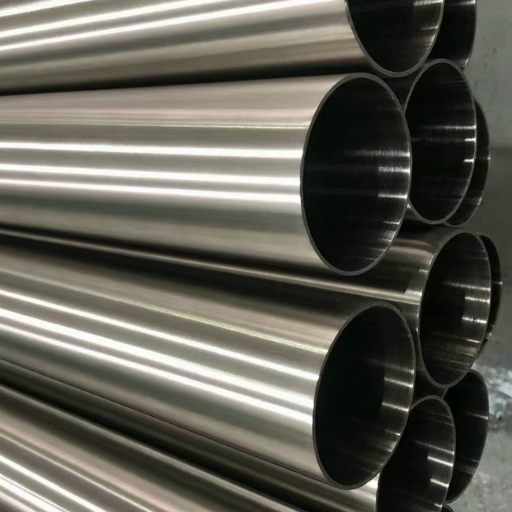

Bright Annealed Stainless Steel Tubing is our premium heat exchanger solution designed for high-efficiency industrial applications like petrochemical, pharmaceutical, and food processing. Manufactured using advanced seamless drawing and bright annealing techniques, these tubes provide exceptional corrosion resistance, strength, and a reflective finish. Available in diameters from 12 mm to 40 mm, wall thicknesses of 0.5 mm to 2.5 mm, and lengths up to 30M, they offer flexibility for custom heat exchanger designs while adhering to international standards such as GB/T, ASTM, and ASME.

The bright annealed finish ensures a smooth, mirror-like surface, critical for industries requiring hygiene and precision, such as medical equipment and HVAC systems. With precise engineering and strict quality controls, Bright Annealed Stainless Steel Tubing delivers consistent performance, even in extreme conditions (-60°F to 480°F, up to 60 bar). Whether for high-pressure heat transfer systems or hygienic applications, these tubes are a reliable choice for long-term efficiency.

Get a Quote

Explore Our Bright Annealed Stainless Steel Tubing types

304 Bright Annealed Stainless Steel Tubing

304 bright annealed stainless steel tubing can be utilized in a variety of applications such as heat exchangers. The tubing’s corrosion resistance, strength and cost-effectiveness make it useful for fluid transfer in food processing, HVAC, or other general-purpose systems. Its smooth and reflective surface and weld integrity allows it to be used in petrochemical and power generation systems. 304 bright annealed tubing is manufactured to international standards which guarantees reliability and effective performance long term.

316 Bright Annealed Stainless Steel Tubing

316 Bright Annealed Stainless Steel Tubing offers superior corrosion resistance for demanding heat exchanger applications. Renowned for its durability and resistance to harsh environments, it excels in transporting fluids in marine, pharmaceutical, and chemical processing systems. Its smooth, mirror-like finish ensures hygiene and efficiency, meeting the needs of high-pressure and high-temperature setups. Manufactured to global standards, 316 bright annealed tubing delivers exceptional performance and long-term reliability.

Get More Information

Contact us today for Bright Annealed Stainless Steel Tubing pricing, availability, or more details. Let us help you find the perfect heat exchanger tubing solution for your industry needs!

Why Choose Us

- Expert Manufacturing: Precision bright annealing ensures smooth, corrosion-resistant tubing for heat exchangers.

- Customizable Options: Tailored 12-40 mm diameters, up to 30M lengths for your needs.

- Certified Excellence: Meets GB/T, ASTM, ASME standards for global quality and durability.

- Factory-Direct Savings: Competitive pricing by cutting intermediaries, offering cost-effective, high-quality tubing.

Bright Annealing Process For Stainless Steel

Unlock the brilliance of stainless steel with our advanced bright annealing process for your unique applications.

Enhanced Surface Finish

The steels smooth surfaces devoid of oxides and impurities are achieved during the bright annealing treatment, providing them a mirror-like sheen. This optimally achieves the corrosion resistance.

Improved Corrosion Resistance

Bright annealing improves stainless steel's corrosion resistance. The procedure smoothes the surface impurities and forms a protective coating that endures rough conditions, guaranteeing enduring reliability.

Eco-Friendly Processing

An example of our eco-friendly procedures in producing stainless steel is energy efficient annealing which minimizes waste and enables us to maintain quality while reducing the environmental impact.

Controlled Atmosphere Precision

Bright annealing takes place under carefully controlled conditions devoid of oxygen, so there is no oxidation. This process guarantees that the stainless steel retains its natural glow, thus improving its strength and functionality.

Customized Heat Treatment

We tailor the bright annealing process to your stainless steel specifications. Precise temperature control ensures optimal mechanical properties, balancing strength and ductility for your specific needs.

Versatile Industry Applications

The food processing, medical, and automotive industries can use bright, annealed stainless steel. Hygiene and sanitation are of utmost importance, as is the case with applications and steel due to its properties.

Advantages of Bright Annealed Tubing

- The finishing procedure of stainless steel tubing involves the removal of blisters and oxides. Even the removal of these blemishes enhances the beauty of bright annealed stainless steel tubings for application purposes.

- The bright annealing process enhances the corrosion resistance of stainless steel tubing by establishing a surface devoid of oxides. This protective layer guarantees that the tubing endures harsh conditions and is apt for various purposes.

- Bright annealed tubing retains its structural integrity by annealing in a controlled, oxygen-free atmosphere. This enhances durability, allowing the tubing to perform reliably under demanding conditions in high-temperature or high-pressure systems.

- Bright annealing ensures uniform heat treatment, optimizing the mechanical properties of stainless steel tubing. This balances strength and ductility, providing consistent performance for precision applications.

- The contaminants won't adhere themselves due to the bright annealed stainless steel tubing having a smooth and non-porous surface. This is very easy to clean which is a positive impact for the food, pharmaceutical, and biotechnology industry.

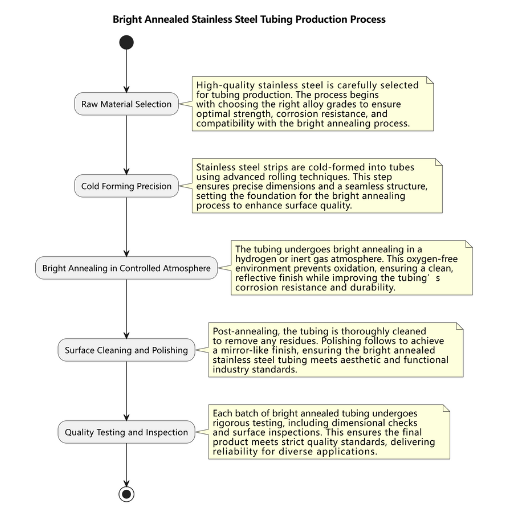

Manufacturing Process

- Tubing Manufacturing starts with choosing the right alloy grades that ensure maximum strength and corrosion resistance while being compatible with bright annealing processes for predictable outcomes.

- Using high-tech rolling methods, stainless steel strips are formed into tubes. Through bright annealing, the parts are held to exact tolerances within infinite boundaries of precise structure to achieve surface refinement.

- The tubing undergoes bright annealing in a hydrogen or inert gas atmosphere. This oxygen-free environment prevents oxidation, ensuring a clean, reflective finish while improving the tubing’s corrosion resistance and durability.

- The tubing is cleaned after annealing to remove all residues without exception. Additional polishing is performed to achieve mirror quality on the bright annealed stainless steel tubing to meet the specifications of beauty and utility in the industry.

- Every lot of tubing undergoes strict processes such as surface examination and geometric verification. This guarantees that severe criteria pertaining to reliability are upheld, fulfilling the requirements for multiple applications and purposes.

Bright Annealed Stainless Steel Tubing Specification Chart

| Category | Details |

|---|---|

| Type | Austenitic Stainless Steel (Grades: 304/304L, 316/316L, 317L, 347/347H, 310S, 309S, 904L) |

| Bright Annealing Temperature | 400°C to 1150°C (depending on grade, e.g., 904L up to 400°C, 310S up to 1150°C) |

| Characteristics | Mirror-like finish, oxide-free surface, enhanced corrosion resistance, hygienic, durable |

| Surface Treatment | Bright annealed in a controlled atmosphere (hydrogen/inert gas), polished for smooth finish |

| Dimensions and Specifications | Outer Diameter: 6mm to 168mm; Wall Thickness: 0.5mm to 3mm; Length: Up to 6 meters |

| Corrosion Resistance | Superior (acidic, chloride environments); Good (oxidation, general corrosion); varies by grade (e.g., 904L excels in sulfuric acid, 316L in marine settings) |

| Mechanical Properties | Moderate to High Strength (e.g., 904L: high strength; 304/316: moderate); Good ductility |

| Processability | Excellent for welding, bending, and forming; suitable for precision machining |

| Applications | Food processing, medical equipment, chemical plants, marine environments, heat exchangers, desalination, pulp & paper industries, high-temperature piping |

| Standards | ASTM A269, ASTM A213, ASME SA213, EN 10216-5, JIS G3463, DIN 17458 |

Expert Guide to Bright Annealed Tubing

What Are the Advantages of Using Seamless Bright Annealed Tubing?

Seamless bright annealed tubing is characterized by its smooth, oxide-free surface, exceptional corrosion resistance, and enhanced durability. It is made without seams to provide greater pressure resistance, improved hygiene, and a polished finish which is suitable for food processing, medicine, and chemical work.

How Does ASTM A269 Affect Bright Annealed Tubing Specifications?

ASTM A269 is a standard specification for seamless and welded austenitic stainless steel tubing for general service. It defines requirements for dimensions, mechanical properties (like tensile strength), and surface finish, ensuring bright annealed tubing meets quality, corrosion resistance, and performance standards for various applications.

What Is the Main Purpose of Annealing?

The main purpose of annealing is to reduce internal stresses, improve ductility, and enhance the material’s workability. For stainless steel tubing, bright annealing also removes oxides, improves corrosion resistance, and creates a polished, reflective surface suitable for aesthetic and functional purposes.

Does Annealing Make a Material Stronger?

That’s right, annealing does not usually increase a materials strength. Rather, it makes it softer by relieving stress which lowers hardness, enhancing ductility as well as toughness. Though, in the case of stainless steel, it does improve overall performance by enhancing corrosion resistance as well uniformity.

Is Annealing Better Than Quenching?

It depends on the goal. Annealing improves ductility and reduces stresses, ideal for forming or corrosion resistance. Quenching rapidly cools the material to increase hardness and strength, suitable for applications needing wear resistance. For bright annealed tubing, annealing is preferred for surface finish and flexibility.

Can You Harden After Annealing?

Indeed, you can harden after annealing by cold working or heat treatment like quenching and tempering. For stainless steel, annealing does soften the material, yet hardening steps can be taken to achieve required strength depending on the alloy and application needs.

Resources on Bright Annealed Tubing

✷ Applications of Bright Annealed Tubing✷

Explore the versatile uses of bright annealed stainless steel tubing across industries.

Food Processing Excellence

Medical Equipment Precision

Chemical Industry Durability

Marine Environment Reliability

Heat Exchanger Efficiency

Pharmaceutical Industry Standards

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Frequently Ask Questions

Q: What is the bright annealing definition for BA Tube production?

A: Bright annealing means heat-treating stainless steel in a controlled, oxygen-free atmosphere (e.g., hydrogen or inert gas) to prevent oxidation. For BA Tube production, this process ensures a clean, reflective finish, enhancing corrosion resistance and surface quality.

Q: What are the benefits of using a BA Tube?

A: These tubes have a SAN-1 finish, exceptional corrosion resistance, and improved strength. Its smooth and clean surfaces make it perfect for food processing, medical devices, and chemical applications while ensuring dependability and aesthetic appeal.

Q: How does bright annealing improve BA Tube performance?

A: The process of bright annealing facilitates BA Tube performance by oside and stress relief, polishing, and improving surface finish and corrosion resistance. This guarantees that the tubing can endure harsh conditions for tough applications such as chemical and marine systems.

Q: What industries commonly use BA Tube products?

A: BA Tube products are widely used in food processing, pharmaceuticals, medical equipment, chemical plants, marine environments, and heat exchangers. Their bright finish and corrosion resistance meet stringent industry standards for hygiene and durability.

Q: Can BA Tube be customized for specific applications?

A: That’s right, the BA Tube is customizable in terms of dimensions, grades and finishes. The bright annealing technique also permits modification of mechanical properties, which for example, is important for aerospace or pharmaceutical industries.

Q: How is the quality of a BA Tube ensured after bright annealing?

A: The quality of a BA tube is ensured through rigorous post-bright annealing testing, including dimensional checks, surface inspections, and corrosion resistance tests. This guarantees the tubing meets strict standards for performance and reliability in various applications.