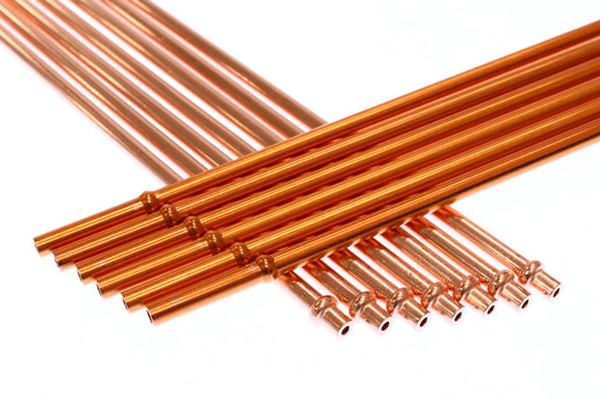

High-Quality Capillary Copper Tube Solutions

Engineered for precision and durability, our capillary copper tubes are ideal for HVAC, refrigeration, and industrial applications. With superior thermal conductivity, corrosion resistance, and eco-friendly properties, they ensure efficient performance and long-lasting reliability. Perfect for energy-efficient systems and sustainable construction, these tubes meet the highest industry standards. Their compact design and versatility make them suitable for diverse installations, from medical gas systems to advanced cooling solutions. Choose our capillary copper tubes for unmatched quality, sustainability, and performance in every project.

What Is a Capillary Copper Tube?

A capillary copper tube is a small-diameter tube essential for controlling refrigerant flow in cooling systems. Made from high-purity copper, its precise internal diameter is critical for regulating pressure and temperature. Primarily used in refrigeration, air conditioning (HVAC), and precision instrumentation, these tubes ensure efficient heat exchange and system longevity due to copper’s excellent thermal conductivity and corrosion resistance. Their consistent performance makes them a vital component for modern cooling technology.

Explore the Advantages of Capillary Copper Tube

Our tubes are engineered to deliver exceptional performance, reliability, and longevity across various demanding applications.

High Thermal Conductivity

Experience superior heat transfer with our high-purity copper, ensuring your systems operate at peak efficiency and reduce energy consumption.

Precision Manufacturing

Benefit from consistent and reliable performance. Each tube is manufactured to exact specifications, guaranteeing uniform flow characteristics and quality.

Exceptional Corrosion Resistance

Count on long-lasting performance. Our tubes are manufactured to resist corrosion, ensuring system integrity and minimizing maintenance needs over time.

Versatile Applications

From HVAC and refrigeration to complex instrumentation, our capillary tubes offer the flexibility to meet the demands of a wide range of industries.

Detailed Specifications of Capillary Copper Tube

| Specification | Standard Range | Tolerance |

|---|---|---|

| Outer Diameter (OD) | 1.8 mm - 5.0 mm | ±0.05 mm |

| Inner Diameter (ID) | 0.5 mm - 3.5 mm | ±0.02 mm |

| Wall Thickness | 0.4 mm - 1.5 mm | ±0.03 mm |

| Length | 2.0 m - 50.0 m (Coils) | ±1% |

| Material Purity | C12200 (Cu-DHP) >99.9% | - |

| Temper | Soft Annealed / Hard Drawn | - |

| Standard Compliance | ASTM B360, EN 12450 | - |

Why Choose Our Capillary Copper Tube?

- Unmatched Quality: We adhere to strict international standards, including ASTM B360, ensuring every tube delivers superior reliability and safety for your critical applications.

- Expert Manufacturing: Our advanced production techniques guarantee exceptional precision in every tube, providing consistent performance that you can depend on for all your system requirements.

- Dedicated Support: Our experienced team provides expert technical support and guidance, helping you select the perfect product and ensuring seamless integration from start to finish.

- Competitive Pricing: We offer high-quality products at competitive prices, providing excellent value without compromising on performance, helping you optimize your project budget.

- Reliable Delivery: With a streamlined supply chain and efficient logistics, we ensure your orders are delivered on time, minimizing project delays and keeping your operations running smoothly.

Applications of Capillary Copper Tube

HVAC Systems

Refrigeration Units

Instrumentation

Heat Exchangers

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Upgrade with Reliable Copper Tubes Today!

Upgrade to durable, corrosion-resistant copper tubes for efficient HVAC, plumbing, and industrial applications. Trusted for sustainability, thermal performance, and reliability, copper tubes are the smart choice for modern construction and energy-efficient systems. Choose quality—choose copper today!

Frequently Ask Questions

Q: What is the lifespan of your capillary copper tubes?

A: Our capillary copper tubes are manufactured from high-purity C12200 copper, known for its excellent corrosion resistance. Under normal operating conditions within HVAC and refrigeration systems, they are designed to last for the entire service life of the unit, often exceeding 15-20 years.

Q: How do you ensure the quality of your tubes?

A: We enforce a strict quality control process that begins with raw material inspection and continues through every stage of manufacturing. Each tube is tested for dimensional accuracy, material composition, and cleanliness to ensure it complies with industry standards like ASTM B360 and ASTM B280.

Q: Can you provide custom dimensions for capillary tubes?

A: Yes, we specialize in providing custom solutions. We can manufacture capillary tubes to your specific outer diameter, inner diameter, wall thickness, and length requirements, whether you need straight lengths or coils. Contact our technical team to discuss your project.

Q: What makes copper a better choice than other materials?

A: Copper’s high thermal conductivity allows for more efficient heat transfer than materials like aluminum or steel, leading to better system performance and energy savings. Its natural resistance to corrosion also ensures greater longevity and reliability, reducing the risk of leaks and system downtime.

Q: How are the tubes packaged for shipping?

A: To ensure our products arrive in perfect condition, capillary tubes are carefully packaged to prevent damage during transit. Coils are typically secured and boxed, while straight lengths are bundled and protected with wrapping to maintain their integrity.

Q: Are your tubes compliant with international standards?

A: Absolutely. Our capillary copper tubes are manufactured to meet or exceed major international standards, including ASTM, EN, and JIS. This commitment to compliance guarantees that our products are safe, reliable, and suitable for use in global markets.