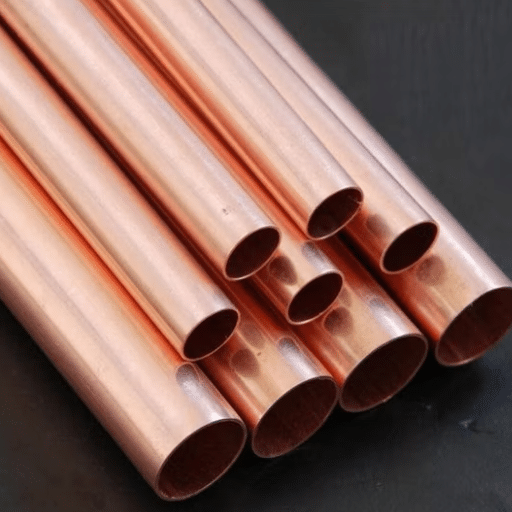

Engineered for the safe and reliable distribution of natural gas and propane within residential and commercial buildings, Gas Copper Tube is the industry standard for fuel gas piping. Its seamless construction provides leak-proof integrity, while its inherent corrosion resistance guarantees a long, maintenance-free service life. Often supplied in flexible coils, it allows for faster, easier installation with fewer joints, significantly enhancing the overall safety of the system. It is the trusted material of choice for a durable and secure fuel gas infrastructure.

Get in touch with us

Leave a message