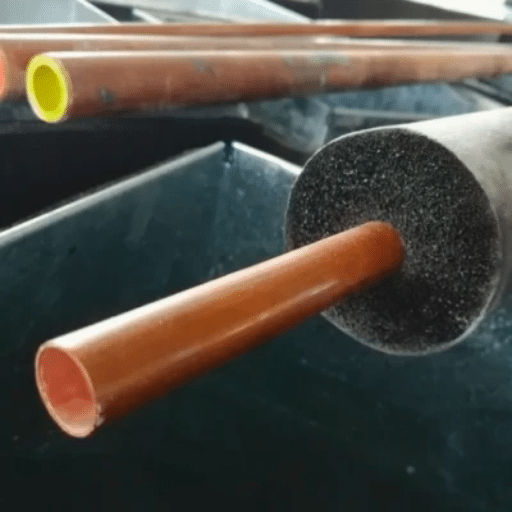

High-Quality Heating System Copper Tube Solutions

As plumbing systems evolve, the choice of materials becomes pivotal in ensuring durability and efficiency. Copper pipes have long been the cornerstone of plumbing solutions due to their exceptional qualities. Copper plays an integral role in HVAC systems due to its exceptional thermal conductivity and durability. In these systems, copper tubing is used extensively for refrigerant lines, ensuring efficient heat transfer and system reliability.

What is Heating System Copper Tube?

A heating system copper tube is a specialized type of copper tubing designed for use in heating systems, such as HVAC (Heating, Ventilation, and Air Conditioning), boilers, and radiant heating. These tubes are known for their excellent thermal conductivity, durability, and resistance to corrosion, making them ideal for efficiently transferring heat in residential, commercial, and industrial applications.

Explore the Advantages of Heating System Copper Tube

Copper tube has been the preferred material for heating systems for over a century. Its unique combination of thermal, mechanical, and chemical properties delivers unmatched performance and reliability.

Exceptional Thermal Conductivity

Copper's thermal conductivity of 330 W/m·K (for C12200 phosphorus-deoxidized copper) is significantly superior to steel, aluminum, and plastic alternatives. This means faster heat transfer, more efficient energy usage, and quicker system response times.

Superior Corrosion Resistance

Copper forms a protective oxide layer that prevents further corrosion. Unlike steel that rusts or galvanized pipes that deteriorate, copper maintains structural integrity in water, glycol solutions, and condensate environments for 50+ years.

Excellent Mechanical Strength

Available in hard (drawn) and soft (annealed) tempers to match application requirements. Hard temper provides rigidity for visible installations. Soft temper allows easy bending and forming, reducing fittings needed by up to 70%.

Easy Installation & Joining

Copper tubes can be soldered, brazed, or mechanically joined with simple tools. Soft temper bends by hand or with basic benders. Installation time reduced by 40% compared to threaded steel pipe systems.

Detailed Technical Specifications of Heating System Copper Tube

| Nominal Size | Outside Diameter (mm) | Wall Thickness Type K (mm) | Wall Thickness Type L (mm) | Wall Thickness Type M (mm) | Weight Type L (kg/m) |

|---|---|---|---|---|---|

| 1/4" | 6.35 | 0.89 | 0.76 | 0.64 | 0.13 |

| 3/8" | 9.52 | 1.24 | 0.89 | 0.71 | 0.23 |

| 1/2" | 12.7 | 1.27 | 1.02 | 0.81 | 0.36 |

| 5/8" | 15.88 | 1.65 | 1.14 | 0.89 | 0.49 |

| 3/4" | 19.05 | 1.65 | 1.27 | 0.89 | 0.67 |

| 1" | 25.4 | 1.65 | 1.27 | 1.07 | 0.9 |

| 1-1/4" | 31.75 | 1.78 | 1.4 | 1.14 | 1.25 |

| 1-1/2" | 38.1 | 1.78 | 1.52 | 1.27 | 1.64 |

| 2" | 50.8 | 2.11 | 1.78 | 1.52 | 2.56 |

| 2-1/2" | 63.5 | 2.41 | 2.03 | 1.78 | 3.65 |

| 3" | 76.2 | 2.77 | 2.29 | 2.03 | 4.96 |

Why Choose Our Heating System Copper Tube?

- Every lot comes with complete mill test reports (MTRs) documenting chemical composition, mechanical properties, and dimensional accuracy. Full traceability from copper cathode to finished tube. ASTM B88, EN 1057, and EN 12735-1 certified. Third-party inspection available.

- Our precision manufacturing maintains tolerances of ±0.05mm on wall thickness and ±0.10mm on outside diameter—tighter than ASTM standards require. This ensures perfect fit with fittings, reliable joint strength, and predictable performance. Zero tolerance for out-of-round tube.

- Built to withstand high temperatures and pressures, our copper tubes provide long-lasting reliability in demanding environments.

- Designed to resist rust, scaling, and wear, ensuring a longer lifespan and reduced maintenance costs.

Applications of Heating System Copper Tube

Radiant Floor Heating

Hydronic Baseboard Heating

Snow Melting Systems

Commercial HVAC Systems

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Discover High-Quality Heating System Copper Tube

If you are ready to enhance your plumbing system with copper or need more information on the best type of copper pipe for your specific needs, we invite you to contact us. Our team of experts is here to provide guidance, answer your questions, and ensure you make an informed decision. Don’t hesitate to reach out and discover how copper can transform your plumbing and heating systems.

Frequently Ask Questions

Q: How is copper pipe installed in a plumbing system?

A: Installing copper pipe in a plumbing system typically involves measuring and cutting the pipe to the desired lengths. It is essential to ensure that the pipe has the appropriate wall thickness for its intended use, especially in high-pressure applications. Joining copper pipes can be done using soldering, brazing, or mechanical fittings. Proper installation techniques are crucial to prevent leaks and ensure efficient water flow.

Q: What are the main types of copper pipes used in HVAC systems?

A: The main types of copper pipes used in HVAC systems include type K, type L, and type M. Type K copper pipe has the thickest walls and is often used for underground applications or where high pressure is expected. Type L is commonly used for water supply lines, while type M has thinner walls and is typically used for indoor plumbing applications. Each type has its specific applications and advantages, making them suitable for various heating and cooling needs.

Q: Can copper tubing be used for hydronic heating?

A: Yes, copper tubing is an excellent choice for hydronic heating systems. Its high thermal conductivity allows for efficient heat transfer to water, creating effective heating solutions. Copper pipes are often used to distribute water in these systems, ensuring uniform heat distribution throughout the space. Additionally, the durability and corrosion resistance of copper make it ideal for long-term use in hydronic applications.

Q: What are the cons of using copper pipes in plumbing?

A: While copper pipes have many advantages, there are some cons to consider. Copper is a more expensive material compared to alternatives like PVC or PEX. Additionally, copper pipes can be susceptible to corrosion, particularly in acidic or hard water conditions. This can lead to leaks and reduced lifespan. It’s essential to assess water quality and maintenance needs when using copper in plumbing systems.

Q: How does copper's antibacterial properties benefit water applications?

A: Copper’s antibacterial properties significantly benefit water applications by reducing the risk of bacterial growth in plumbing systems. This characteristic is particularly important in potable water supply lines, where maintaining water quality is crucial. The use of copper pipes can help ensure that the water delivered is safer and healthier, contributing to overall public health and safety.

Q: What should be considered when maintaining copper pipe installations?

A: When maintaining copper pipe installations, it is essential to regularly inspect for signs of corrosion or leaks. Proper water quality should be monitored, as acidic water can accelerate corrosion. Additionally, ensuring that joints and fittings are secure will help prevent leaks and maintain efficient water flow. Regular maintenance not only prolongs the life of copper pipes but also ensures optimal performance in heating and plumbing systems.