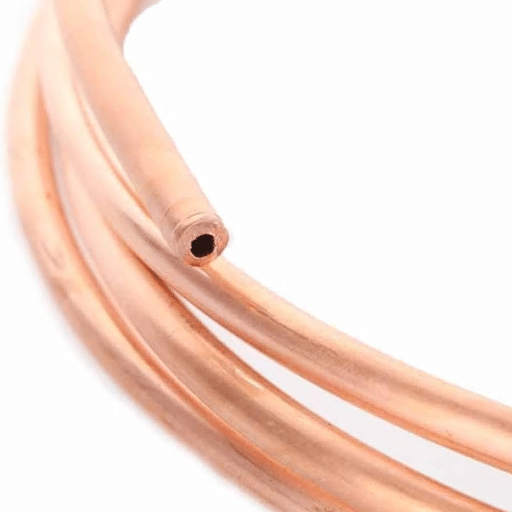

When it comes to HVAC systems, the quality of your components determines the performance and longevity of the entire unit. Copper tubing is the industry standard for a reason. Its exceptional thermal conductivity, proven durability, and natural resistance to corrosion make it the most reliable material for transporting refrigerants.

Get in touch with us

Leave a message