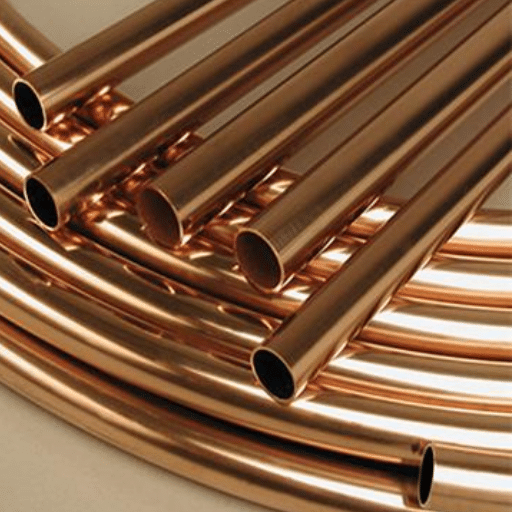

High-quality Industrial Copper Tube meets your needs

Copper pipes, tubes, and tubing are integral components in various industries, particularly in HVAC and refrigeration systems. Renowned for their excellent thermal conductivity and electrical properties, these copper products are designed to withstand the rigorous demands of modern applications. Whether it’s for air conditioning systems or refrigeration units, copper’s durability and resistance to corrosion make it a preferred choice among manufacturers and engineers. From coils and fittings to straight lengths, copper’s versatility is unmatched.

What is Industrial Copper Tube?

Industrial copper tubes are specialized tubing products manufactured from copper, known for their durability, corrosion resistance, and superior thermal and electrical conductivity. These tubes are widely used in various industries, including HVAC (Heating, Ventilation, and Air Conditioning), plumbing, refrigeration, and manufacturing. Industrial copper tubes are available in different types, such as soft and hard temper, and come in various sizes and thicknesses to meet diverse application requirements. Their reliability, ease of installation, and ability to withstand high pressures and temperatures make them a preferred choice for both industrial and commercial systems.

A Glimpse into the Advantages of Industrial Copper Tube

Industrial copper tubes are essential components renowned for their durability, corrosion resistance, and excellent thermal conductivity, making them indispensable in plumbing, HVAC, and manufacturing applications.

Durability and Longevity

Industrial copper tubes resist corrosion and wear, ensuring a long lifespan even in harsh environments.

Superior Thermal Conductivity

Copper tubes excel in efficiently conducting heat, making them ideal for HVAC, refrigeration, and industrial heating systems.

Eco-Friendly and Recyclable

Copper is fully recyclable without losing quality, offering a sustainable solution for industries aiming to reduce environmental impact.

High Pressure Resistance

Copper tubes can withstand high pressures, ensuring reliability in industrial applications where robust performance is critical.

Detailed Specifications of Industrial Copper Tube

| Specification | Details | Applications |

|---|---|---|

| Material | High-purity copper | HVAC systems |

| Diameter Range | 1/8 inch to 8 inches | Plumbing installations |

| Wall Thickness | 0.02 inches to 0.25 inches | Industrial refrigeration systems |

| Length Options | 6 ft to 20 ft | Medical gas delivery systems |

| Temperature Resistance | Up to 400°F (204°C) | Heat exchangers |

| Pressure Rating | Up to 700 psi | Hydraulic systems |

| Corrosion Resistance | Excellent | Chemical processing plants |

| Conductivity | High thermal/electrical | Electrical wiring |

| Standards Compliance | ASTM B88, B280 | Structural applications |

| Finish Options | Smooth, textured, coated | Architectural purposes |

Why Choose Our Industrial Copper Tube?

- Exceptional durability ensures long-lasting performance, making it ideal for demanding industrial applications in various environments.

- Premium-quality copper enhances conductivity and corrosion resistance for superior efficiency and reliability in all operations.

- Customizable sizes and specifications cater to diverse industrial needs, providing flexibility and ease of installation.

- Competitive pricing combined with outstanding product quality offers excellent value for your investment.

- Dedicated customer support and prompt delivery ensure a seamless purchasing experience from start to finish.

Applications of Industrial Copper Tube

HVAC Systems

Plumbing

Refrigeration Industry

Automotive Manufacturing

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Discover the Versatility of Industrial Copper Tubes

Industrial copper tubes are essential for various applications, offering reliability, durability, and excellent thermal conductivity. Whether you need them for HVAC systems, plumbing, or industrial machinery, these tubes deliver unmatched performance and efficiency. Explore how industrial copper tubes can meet your specific needs with precision and long-lasting results. Start optimizing your operations with this trusted material today!

Frequently Ask Questions

Q: What are the primary uses of industrial copper tubes?

A: Industrial copper tubes are widely used in HVAC systems, plumbing, refrigeration, and heat exchangers due to their excellent thermal conductivity, corrosion resistance, and durability. They are also utilized in manufacturing and industrial applications where reliable and efficient fluid conveyance is essential.A: Plumbing copper tube is commonly used for water supply lines, heating systems, and refrigerant lines in HVAC systems. Its durability, resistance to corrosion, and ability to handle extreme temperatures make it a reliable choice for both residential and commercial applications.

Q: Why is copper preferred over other metals for industrial tubing?

A: Copper is highly durable, resistant to corrosion, and offers superior thermal and electrical conductivity compared to many other metals. Its versatility, recyclability, and ease of fabrication also make it a cost-effective and sustainable choice for industrial applications.

Q: How is industrial copper tubing manufactured?

A: Industrial copper tubing is typically manufactured through processes like extrusion and drawing. This involves melting high-purity copper and shaping it into tubes, followed by cooling, sizing, and additional treatments to achieve the required specifications and tolerances.

Q: What types of copper tubes are available for industrial use?

A: Common types of industrial copper tubes include Type K, L, and M for plumbing and HVAC applications, as well as specialized tubes like ACR (Air Conditioning and Refrigeration) and pancake coils. Each type varies in thickness and flexibility to suit specific industrial needs.

Q: How should industrial copper tubes be maintained to ensure longevity?

A: Regular inspection for debris, corrosion, or leaks is important. Cleaning the tubes with appropriate solutions and ensuring proper insulation in environments where moisture or abrasives are present can significantly extend their lifespan.

Q: Can industrial copper tubes be customized for specific applications?

A: Yes, industrial copper tubes can be customized in terms of dimensions, wall thickness, and length to meet the unique needs of different industries. Many suppliers also offer custom coatings or pre-insulated options for specialized applications.