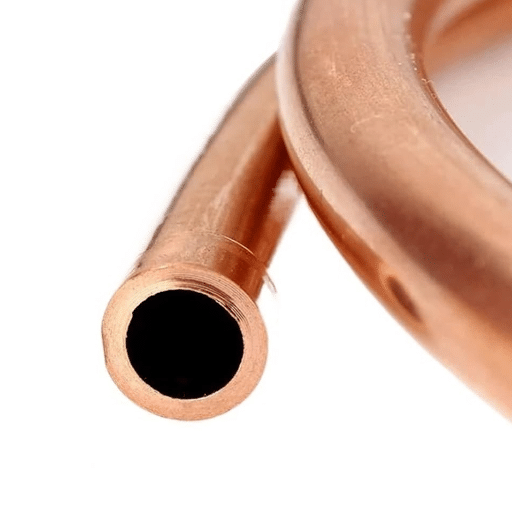

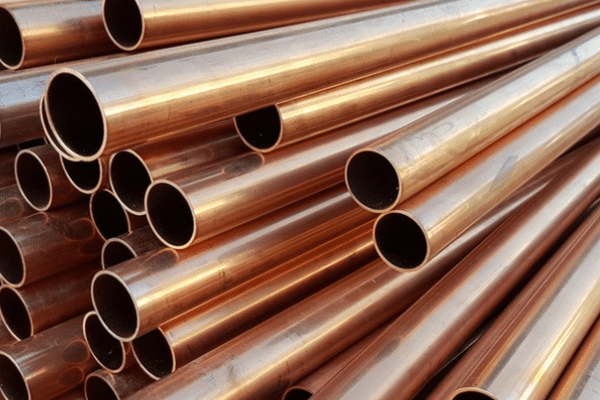

In today’s demanding industrial landscape, performance, reliability, and precision are not optional. We specialize in the manufacturing of high-quality copper tubes, engineered to meet the strictest specifications for a wide range of applications. Our state-of-the-art production process ensures every tube delivers superior thermal and electrical conductivity, exceptional durability, and unparalleled corrosion resistance. From intricate machinery components to critical automotive systems, our copper tubes provide the foundation for excellence.

Get in touch with us

Leave a message