Top Sanitary Valve Manufacturer in China

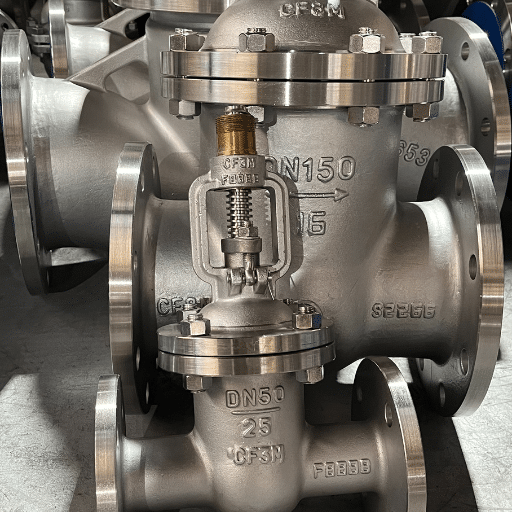

The sanitary valve is the latest evolution in hygienic fluid control, meticulously engineered to meet the most demanding requirements of industries such as biopharmaceuticals, food processing, and personal care. Combining cutting-edge technology with robust design, this valve delivers unmatched precision, reliability, and versatility.

Sanitary Valve

- Material Excellence

- Advanced technology

- Sanitary Design

Overview :

Description :

Sanitary valves play a critical role in maintaining hygiene and efficiency across industries where fluid control is essential. Designed to meet the rigorous demands of modern processing environments, these components ensure smooth operation while supporting the safe handling of sensitive materials. Their integration into a well-structured valve system delivers reliable performance, minimizing contamination risks and enhancing overall operational precision.

With a focus on durability and cleanliness, sanitary valves and fittings are engineered for seamless compatibility with diverse applications. They facilitate streamlined processes by adapting to various system requirements, offering both functionality and ease of use. Their high-quality design ensures consistent performance, making them indispensable in environments where reliability is paramount.

Get a Quote

Explore Our sanitary valve types

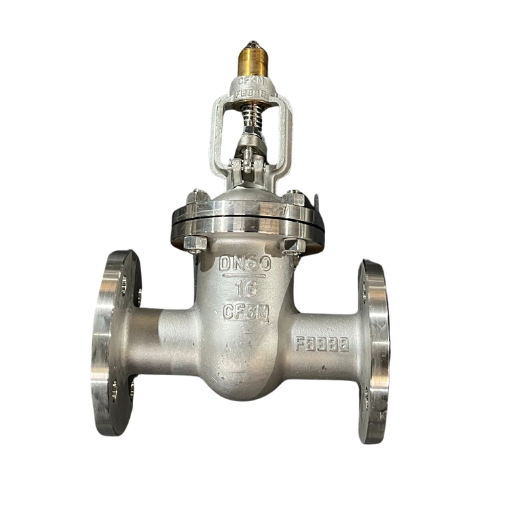

Sanitary Gate Valves

Sanitary Gate Valves are used primarily for on-off control, providing a clear, unimpeded flow path when fully open. While less common in critical aseptic processes due to the potential for material accumulation in the gate pocket, they are valued for their full bore design, which minimizes pressure drop and is suitable for viscous media or slurries in less sensitive sanitary or utility applications. Our sanitary designs incorporate features to mitigate cleanliness challenges where possible, ensuring reliable shut-off and performance.

Sanitary Ball Valve

Sanitary Ball Valves offer quick, quarter-turn operation for reliable on-off control and tight shut-off. Featuring a polished ball rotating within a smooth body, they provide excellent flow characteristics. Designed with features like cavity fillers or purge ports, sanitary ball valves minimize dead space around the ball and seats, reducing the risk of bacterial growth. They are robust, durable, and widely used in general sanitary processing lines, CIP systems, and utility applications where quick action and positive shut-off are required.

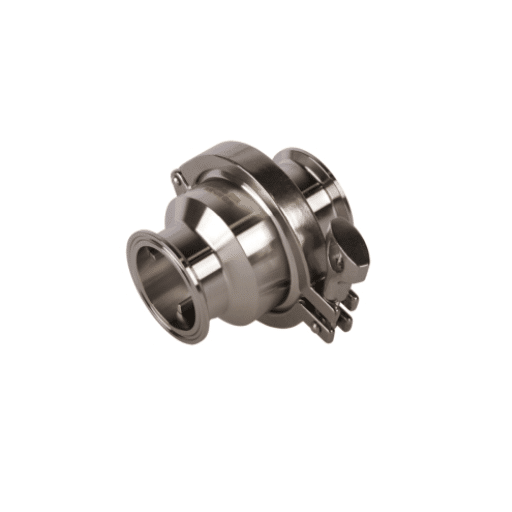

Sanitary Check Valve

Sanitary Check Valves are essential components designed to permit flow in only one direction, effectively preventing backflow and protecting product purity. Available in various designs, including spring-loaded, lift, or swing types, they feature highly polished internal surfaces and hygienic connections to ensure cleanability and prevent contamination. Sanitary check valves are critical for safeguarding pumps, heat exchangers, and process lines against back contamination, maintaining the integrity of the sanitary system.

Sanitary Butterfly Valves

Sanitary Butterfly Valves are compact, lightweight, and economical solutions for flow isolation and control in sanitary piping systems, particularly in larger line sizes. They operate via a rotating disc that pivots within the flow path. While typically used for on-off service, they can also provide throttling capabilities. Sanitary designs feature polished discs and bodies, along with hygienic seats (gaskets) that create a seal against the pipe wall, ensuring cleanability and minimal product retention.

Sanitary Diaphragm Valve

Sanitary Diaphragm Valves are highly regarded for critical sanitary and aseptic applications. Their design features a flexible diaphragm that seals against a weir or straight-through body, effectively isolating the working mechanism (bonnet) from the process fluid. This eliminates potential leak paths and dead spaces, making them exceptionally easy to clean and sterilize. They are ideal for high-purity water, sterile media, slurries, and applications requiring the utmost level of hygienic integrity.

Sanitary Sampling Valve

Sanitary Sampling Valves are specifically designed to extract representative samples from a process line or vessel under hygienic conditions. Engineered to minimize dead legs and ensure the sample port can be effectively cleaned and sterilized (often with steam), these valves prevent contamination of both the sample and the process stream. Available in various configurations, they are crucial for quality control and process monitoring in sensitive sanitary manufacturing.

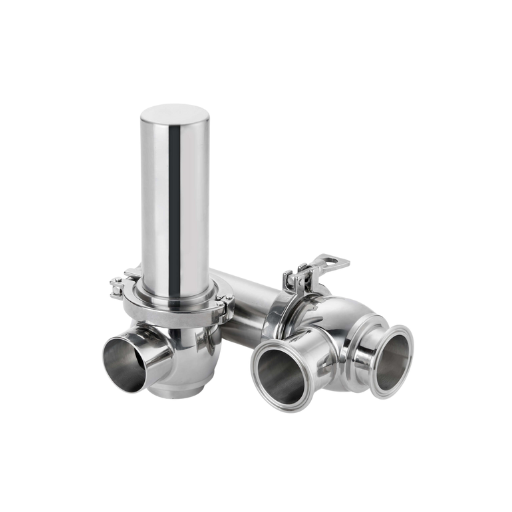

Sanitary Safety Valve

Sanitary Safety Valves are pressure relief devices designed to protect sanitary systems and equipment from over-pressurization while maintaining hygienic conditions. They automatically open when the system pressure exceeds a set point, releasing excess pressure, and then reclose. Built with sanitary connections, polished internal surfaces, and materials compatible with process fluids and cleaning agents, they ensure system safety without compromising product purity or cleanability.

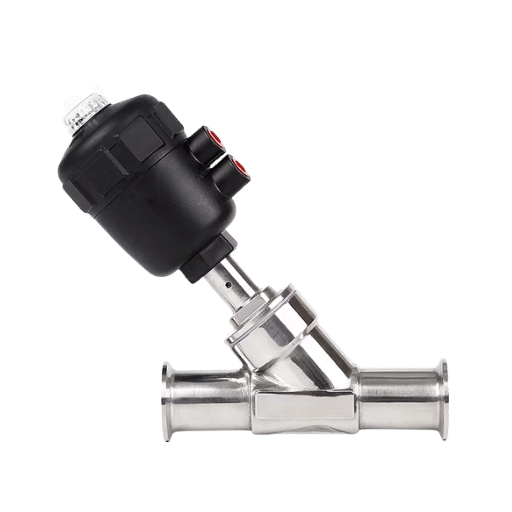

Sanitary Angle Seat Valve

Sanitary Angle Seat Valves are robust, piston-actuated valves known for their high flow rates and durability, especially with challenging media like steam or hot water. The angle seat design promotes self-draining, reducing the risk of product buildup. They are commonly used for controlling utility media like steam, hot water, or inert gases entering the sanitary process, but can also handle viscous or particle-laden process fluids due to their unobstructed flow path when open. Their pneumatic actuation allows for easy automation.

Discover Our Valve Solutions

Contact us today to explore our premium sanitary valves and fittings. Professional sanitary valve manufacturers are ready to assist you in selecting the ideal valve system for your needs. Request a quote or learn more now!

Why Choose Us

- Effective Rate: Factories directly sourcing provides cost-effective deals along with high quality service.

- Personalized Customization: Designed personally and custom made for all types of sanitary valves.

- Assured Quality Control: In-house checks ensure customers on-time delivery that is consistently top-quality and unrivaled.

- Production Run Per Turnaround: Streamlined workflows allows businesses to meet required deadlines.

- Supported Global Shipping: Fully integrated systems supporting international shipping are designed to exclude all difficulties.

Comprehensive Valve System Solutions

Enhance process efficiency and hygiene control with our expertly engineered valve system solutions.

Precision Fluid Control

Optimize performance with sanitary valves for accurate, reliable fluid regulation in demanding processes.

Superior Hygiene Standards

Maintain clean operations with valves designed for easy cleaning, ideal for strict sanitary environments.

Tailored Configurations

Achieve seamless system compatibility with customizable valve systems designed to fit specific operational needs.

Energy-Conscious Design

Support sustainability with valve systems engineered for low resistance, reducing energy consumption during operation.

Long-Term Dependability

Rely on robust valve systems built for durability, ensuring consistent performance and reducing maintenance requirements.

Effortless Integration

Streamline upgrades with sanitary valve systems designed for easy installation and minimal disruption.

Advantages of Sanitary Valve

- Sanitary valves ensure exceptional hygiene standards, making them vital for industries like food, pharmaceuticals, and biotechnology where contamination control is crucial.

- Their durable construction delivers reliable performance in challenging conditions, lowering maintenance needs and long-term operational costs for industrial applications.

- Sanitary valves offer precise fluid regulation, allowing efficient control of flow and pressure, which enhances productivity and ensures consistent process outcomes.

- Easy cleaning and maintenance reduce downtime, supporting uninterrupted operations and ensuring productivity remains at optimal levels even during servicing.

- Customizable sanitary valves adapt to specific process requirements, ensuring compatibility with existing systems and delivering seamless performance in complex environments.

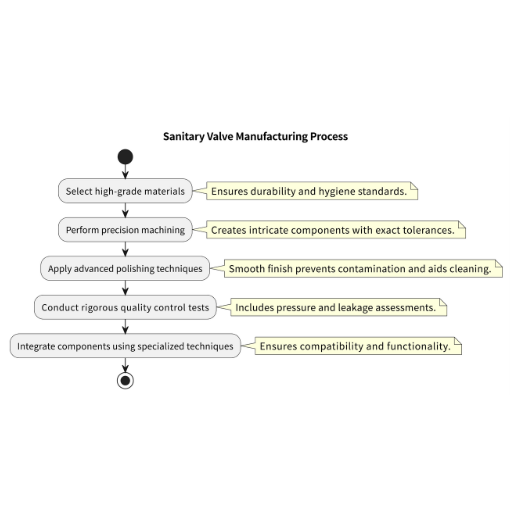

Manufacturing Process

- The manufacturing of sanitary valves begins with selecting premium-grade materials to ensure product durability, reliability, and compliance with strict hygiene regulations.

- Computer-controlled precision machining shapes valve components with exceptional accuracy, meeting exact tolerances for optimal functionality and performance.

- The interiors are carefully polished to a smooth finish, reducing the risk of contamination, promoting hygiene, and enabling easy maintenance in sanitation-critical industries.

- All valves undergo rigorous testing, including pressure, flow, and seal integrity checks, to validate reliability and adherence to quality and performance standards.

- Final assembly involves integrating components with expert care, ensuring compatibility and delivering fully functional sanitary valves ready for operation.

Sanitary Valve Types and Specifications

| Valve Type | Description | Material | Size Range | Pressure Rating | Special Features |

|---|---|---|---|---|---|

| Ball Valve | Offers reliable on/off control using a rotating ball to regulate flow. | Stainless Steel | 0.5–12"" | 100–1500 PSI | Available with PTFE seals for hygiene. |

| Compact design for space efficiency. | |||||

| Butterfly Valve | Lightweight design with a pivoting disc for flow regulation. | Stainless Steel | 1–24"" | 100–300 PSI | Supports manual or automated operation. |

| High-flow capacity with low resistance. | |||||

| Check Valve | Prevents backflow using a spring-loaded or inline mechanism. | Stainless Steel | 0.5–8"" | Minimal Pressure Drop | Ensures unidirectional flow integrity. |

| Easy to install and maintain. | |||||

| Gate Valve | Controls flow with a movable gate, suitable for slow operation processes. | Stainless Steel | 2–48"" | 150–2200 PSI | High durability for heavy-duty use. |

| Tight sealing for zero leakage. |

Expert Guide to Sanitary Valve

How Do Sanitary Ball Valves Differ from Standard Valves?

Sanitary ball valves are designed precisely to satisfy the cleanliness needs of food processing, pharmaceuticals, and other similar industries. Unlike regular valves, they have polished, crevice-free surfaces that minimize contamination risk. High-quality stainless steel is used along with EU approved seals which guarantees these valves are in alignment with sanitary pipes and fittings systems.

What makes a valve sanitary?

A sanitary valve is engineered to maintain sterile conditions. Its primary attributes consist of smooth polished surfaces free of crevices and hygienic materials like food-grade stainless steel. These attributes render the valve easy to clean, frequently incorporating with clean-in-place (CIP) systems. These designs are perfect for the circumferences requiring sanitary pipe and fittings.

What valves avoid backflow of water?

Check valves are favored for avoidance of backflow. They are particularly important in systems utilizing sanitary pipes and fittings, as they help maintain system integrity and sanitation by permitting flow in only one direction.

How do I choose a valve?

Each type of valve has its unique features which are of importance in the following consideration:

- Application Needs: Delineate the type of media, temperature, and pressure your system interfaces with.

- Hygiene Standards: Use sanitary valves if your process needs sterile conditions and works along with sanitary pipe and fittings.

- Control of Flow: Determine whether you need on/off control, throttling, or flow direction management to select between ball, butterfly, or gate valves.

- Suitability of Material: Check if the valve material would not be subject to corrosion and is compatible with the media.

- Integration with the System: Ensure that the valve conforms to the system pipe diameter and type of connections for optimal functionality.

Should the valve be the same size as pipe?

Usually, a valve’s dimensions should concord with the pipe size for effective functioning alongside sanitary pipe fittings. Nevertheless, some applications may need a valve to be larger or smaller than the nominal size based on the flow or pressure requirements. Consider the system specifications carefully before settling on the valve size.

Resources on Sanitary Valve

✷ The Role of Sanitary Valves in Hygienic Applications ✷

Sanitary Valve offers versatile solutions across industries, combining durability, corrosion resistance, and precision for a wide range of applications.

Food and Beverage Processing

Pharmaceutical and Biotech Industries

Water Treatment and Purification

Cosmetics and Personal Care Products

Chemical Processing Plants

Dairy and Brewing Industries

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Frequently Ask Questions

Q: What is the purpose of a sanitary valve?

A: Sanitary valves are designed to regulate the flow of liquids or gases in systems where hygiene is critical, such as food processing, pharmaceuticals, and cosmetics. They often integrate with sanitary pipe and fittings to maintain cleanliness and prevent contamination.

Q: How does a zero static valve improve system hygiene?

A: A zero static valve is engineered to eliminate pockets where fluids might stagnate, ensuring that the system remains contaminant-free. This design is ideal for processes requiring strict hygiene and easy cleaning.

Q: What materials are used in sanitary valves?

A: Sanitary valves are typically made of high-grade stainless steel to resist corrosion and ensure hygienic operation. Their components, including sanitary fittings, are often polished to smooth out crevices that can harbor bacteria.

Q: What industries commonly use sanitary valves?

A: Sanitary valves are widely used in industries like food and beverage production, pharmaceuticals, water treatment, and personal care products, where sterility and precision are paramount.

Q: How are sanitary valves cleaned?

A: Most sanitary valves are compatible with clean-in-place (CIP) and steam-in-place (SIP) systems, which allow thorough cleaning without disassembly. This makes them efficient for maintaining high hygiene standards.

Q: What factors should be considered when selecting a sanitary valve?

A: Key factors include the type of media, operating temperature, pressure, and compliance with industry standards. Choosing valves that easily integrate with sanitary pipe and fittings can also streamline installation and maintenance.