Sanitary valves are important in the food and beverage industry because they maintain the cleanliness, safety, and efficiency of processing operations. These parts are made to comply with the most rigid hygiene and sanitation requirements while safeguarding the integrity of the product. A sanitary valve serves many purposes, such as fluid flow control and contamination prevention; thus, it is an essential element of modern processing systems. This article will explain the significance of sanitary valves, the types used within the industry, and considerations in choosing the right valve for your operations. With this guide, vital information concerning the world of manufacturing, engineering, and the processes behind food and beverage production will be illuminated for the reader.

What Exactly is a Sanitary Valve and How Does it Work?

A sanitary valve is a type of valve employed in food processing, pharmaceuticals, and beverage production that requires high levels of hygiene. These valves prevent contamination through the absence of dead ends/bacteria crevice surfaces. They operate by opening, closing, or regulating the flow of liquid through a system, usually done with manual, pneumatic, or electric actuators. The construction of these valves makes them easy to clean and compliant with stringent sanitary requirements.

Definition and Basic Functions of Sanitary Valves

Each type of sanitary valve serves a particular application and function in sensitivity pertaining to hygiene for different industries. The most common types include butterfly valves, ball valves, diaphragm valves, and check valves.

- Butterfly Valves: Compact in shape, easier to operate, and used in applications with quick shut-off requirements—butterfly valves do it all. They function using a flat circular disc that regulates flow by pivoting and closing it.

- Ball Valves: Control suction and flow up and down with complete shut off–these features make ball valves reliable, thanks to the spherical disc they feature for flow control.

- Diaphragm Valves: Featuring flexible diaphragms that take the shape of the valve’s sides, these are popular for precision in flow control and applications needing ultra high cleanliness.

- Check Valves: The primary function of these valves is to ensure that a liquid continuously flows in one direction, and they prevent backflow.

Different industries forecast that the global sanitary valve market will grow in the coming years due to increased demand from the pharmaceutical and food processing industries. For instance, some newer valve manufacturing technologies have the capabilities of withstanding higher operating pressures and temperatures which widens the range of potential applications. Components such as stainless steel 316L which is highly resistant to corrosive, easy to sterilize, and compliant to FDA and 3-A sanitary regulations make modern sanitary valves critical for the food processing industry.

How Sanitary Valves Control the Flow in Processing Systems

Sanitary valves are crucial in the exact and hygienic operation of controlling the flow of liquids, semi-solids, and even gases in a processing system. Such valves are designed in the way that they offer smooth surfaces without any crevices which increases the risk of contamination and bacterial presence. A common type of a sanitary valve is a diaphragm valve and it uses flow regulation via a flexible membrane which creates a good seal capable of stand-alone and throttling applications.

Industry insight suggests that the adoption of sanitary valves due to higher requirements of hygienic processing equipment in food, beverages, and pharmaceuticals is rapidly increasing. Data suggests that the global sanitary valve market revenue is set to reach several billion in 2030 with a CAGR of over 5%. This growth indicates a shift in focus for the high-quality materials used, such as stainless steel alloys, along with new design innovations like self-draining and CIP (Clean-in-Place). Such practices enable compliance with set regulations while maximizing the operational economy.

As an example, the implementation of smart valves on sanitary valves used within the industry is one of the major developments. Automation and sensors have made it possible for operators to track valve performance in real-time, mitigating the chances for downtime and product loss. This type of technology strengthens the importance of sanitary valves as critical parts for safety, quality, and process efficiency in many industries.

Key Differences Between Sanitary Valves and Industrial Valves

Both sanitary valves and industrial valves serve different types of applications, which affect their constructions, functionalities, and use cases. Sanitary valves operate in the food, beverage, pharmacy, and biotechnology industries, which require a high level of cleanliness and order. For these purposes, valves are made of corrosion-resistant stainless steel, polished to perfection to prevent contamination and to make processes like Clean-in-Place and Sterilize-in-Place cleaning efficient. To add, sanitary valves also tend to follow guidelines such as the FDA and EHEDG to ensure safety and hygiene.

While sanitary valves focus on cleanliness, industrial valves are used in wider and more strenuous settings like oil and gas, chemical processing, and power generation. Industrial valves are built to withstand high amounts of pressure, extreme temperatures, and abrasion or corrosive materials, which makes these valves more durable. They tend to use more durable materials such as cast iron, carbon steel, and other alloys, depending on the application. Unlike sanitary valves, industrial valves do not focus as much on cleaning and more on the harsh conditions the valve will be put through.

One of the differences between the two is how much they cost and their complexity of design. Because sanitary valves are made with specialized materials, are surface finished, and strict to hygiene standards, they are typically much more expensive. On the other hand, industrial valves can be affordable, but do contain automated features or high pressure resistance which alter their cost. Knowing the difference is important when choosing the right type of valve for the application.

What Types of Sanitary Valves Are Available for Different Applications?

Sanitary valves come in different types to fit the needs of various applications. The most popular include:

- Butterfly Valves: Have low weight and easy to actuate, best for liquids and semi-liquids in food and beverage manufacturing.

- Ball Valves: Give good shutoff and control in high-pressure systems. Used in pharmaceutical and chemical processes.

- Diaphragm Valves: Allow meticulous flow control and are used in applications that require sterility making them popular in bioprocessing.

- Check Valves: Stop backflow from occurring in a system, allowing fluid flow in one direction only. Critical in dairy and water treatment for hygiene and safe operations.

- Pinch Valves: Made for fluids containing suspended solids. Common in slurry and other viscous fluids.

Different types depend on the flow metrics, the characteristics of the medium, as well as the hygiene standards relevant to the application.

Sanitary Ball Valves: Features and Applications

Sanitary ball valves are specially designed for clean and hygienic applications in industries such as food processing, pharmaceuticals, biotechnology, and cosmetics. To facilitate effective cleaning, these valves are designed with rounded interiors that prevent bacteria from accumulating in hard-to-reach areas. Some of the main uses and features of sanitary ball valves are mentioned below:

Features:

- Material Composition: Made of stainless steel like SS304 or SS316L to protect against corrosion and increase durability.

- Hygienic Design: Contains impermeable polish crevices to minimize areas where bacteria can grow.

- Full Bore Design: Has unrestricted flow, which helps decrease the level of drops in pressure and turbulence.

- Sealing Mechanism: Uses food-grade silicone and Teflon/PTFE seals, making the system worthy of safe… leak-proof operation.

- Ease of Maintenance: Maintenance and cleaning are made easier due to the quick disassembling design.

- Temperature and Pressure Resistance: Supports a wider range of temperatures and pressures during sterilization.

Applications:

- Food and Beverage Industry:

-

-

- Regulating the movement of liquids as milk, juices, syrups, and oils.

- Assists in the brewing and production of carbonated beverages.

-

- Pharmaceutical Industry:

-

-

- Safeguards the transfer of heat-sensitive liquids and hazardous chemicals under sterile conditions.

-

- Biotechnology:

-

-

- Very important for regulating the movement of biofluids during research and production.

-

- Cosmetic Industry:

-

-

- Best suited for the management of creams, lotions, and other thick products.

-

- Clean-in-Place (CIP) Systems:

-

-

-

Frequently used to streamline the concentrated cleansing of automated systems, allowing sanitization without taking the system apart.

-

-

Hygienic ball valves play a versatile and reliable role in the maintenance of hygiene across various industries. Which makes them indispensable during the application for cleanliness and the need for precision.

Sanitary Check Valves and Butterfly Valves Explained

Both sanitary check valves and butterfly valves are very important in the food and beverage and pharmaceutical industries as well as in biotechnology which deal with advanced medicines. These valves are made to protect against liquid movement that is either uncontrolled or untidy so that it does not lead to contamination or any back flow.

Sanitary Check Valves facilitate the fluid flow in one direction only and prevent backflow. Their operation is normally automatic, depending on the pressure differentials in the pipes to open and close. They usually have an internal cross-section that is smooth and free of crevices that could trap bacteria. To avoid bacterial infection, the valves are often made of stainless steel so that they can endure the pressures and temperatures of industrial settings and cleaning processes.

- Applications: Commonly used in pasteurization processes, in the dairy and beverage industry, to safeguard pumps and other equipment from the risk of fluid backflow.

- Standards Compliance: Most models comply with 3-A Sanitary Standards, which maintain compatibility with high standards of cleanliness.

- Performance Data:

-

- Operating pressure range is between 0.5 – 10 bar, based on the specific model’s requirements.

-

Models can withstand temperatures of 150°C due to the need for sterilization.

Sanitary Butterfly Valves provide effective control of flow, regardless of fluid viscosity. Their intuitive design and compact stature make them suitable for industries requiring hygiene and accuracy.

- Design:

-

- Typically features a disk mounted on a rotating shaft. When fully open, the disk aligns with the flow, causing minimal pressure loss.

- Mixtures of materials are not easy to clean, therefore, the Internal surfaces must be free of gaps, grooves, etches, scratches, or rough patches.

- Applications:

-

- For product flow control in processes like brewing, cosmetics, and chemical processes.

- Ease manual and automated implementations with pneumatic or electric options available for actuation.

- Performance Data:

-

- Operating reliably at 16 bar pressure will not compromise the leak-proof sealing mechanisms.

-

With pipeline dimensions from 30 mm to 190 mm, these valves can be produced within the 1” to 12” range.

Both sanitary check valves and butterfly valves are critical for preserving product quality and ensuring operational efficiency in hygienic industries. With appropriate investment in patented sanitary valves with butterfly systems, businesses can achieve operational excellence while satisfying demanding sanitation regulations.

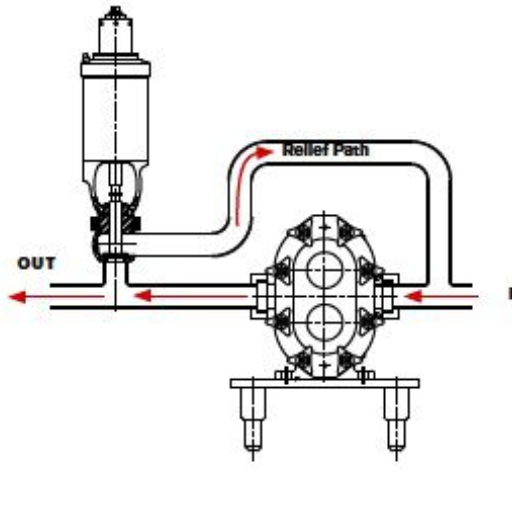

Diaphragm Valves and Relief Valves in Sanitary Systems

Thanks to the crevice-free construction of diaphragm valves, which allows for easy cleaning between operations, these components are very useful for hygienic processes, as there is no accumulation of product residue. These valves are specifically useful for the food, beverage, and pharmaceutical industries where sterile conditions are mandatory. The valves are elastomer diaphragms with stainless steel bodies, which allow corrosion resistance, making them dependable for flow control while meeting regulatory requirements like FDA and EHEDG.

In contrast, relief valves manage overpressure scenarios in sanitary systems. They relieve excess pressure automatically, thus protecting pipelines and equipment from system damage and production downtime. Today, modern relief valves maintain precision with varying conditions and are capable of handling pressure requirements of 25 bars or greater bars depending on the application. These valves, along with specific diaphragm and relief valves, help businesses achieve consistent results while maintaining hygiene and safety standards.

Why Are Sanitary Grade Valves Essential in Certain Industries?

Sanitary grade valves are critical in food and beverage, pharmaceuticals, and biotechnology industries as they ensure the careful handling of delicate products. These valves are designed to avoid contamination and strist regulatory requirements. They have smooth surfaces, easy-to-clean designs, and minimal bacteria buildup, which upholds product integrity and consumer safety. The use of sanitary grade valves allows industries to comply with health regulations and sustain high production value.

Food and Beverage Processing Requirements

Manufacturers in the food and beverage sector are required to maintain strict product safety and quality standards. One of the main requirements for food processing operations is to ensure effective sanitary design of all equipment, like valves, pumps, and pipelines. As stated in some industry studies, foodborne illnesses are estimated to occur in 48 million cases in the United States each year, which highlights the necessity for more hygienic practices. Federal guidelines, like those issued by the FDA and USDA, require the application of non-toxic, corrosion-resistant, easy-to-sanitize materials of food-grade type.

Another integral part is temperature maintenance, which affects product quality and microbial proliferation. In addition, any pasteurization process must contain certain temperature parameters, for example, to safely pasteurize milk, it has to be held at 161 °F for at least 15 seconds. In addition, new technologies like precise automation systems are in demand because they offer real monitoring and control, which minimizes the chances for contamination while maximizing productivity. These enable food and beverage manufacturers to meet the requisite standards without undermining the workflow.

Pharmaceutical and Biotechnology Applications

Monitoring temperature and sterilization procedures are vital in the pharmaceutical and biotechnology industries to make sure products are safe and effective. For example, in biopharmaceuticals, highly specific temperature controls are often needed to protect biological materials like proteins or enzymes. Products could be rendered unusable if optimal conditions are not maintained.

Most modern facilities have started employing sophisticated cryogenic storage systems, housing biological samples and vaccines at temperatures of -196°C (using liquid nitrogen). The creation of mRNA vaccines has underscored the need for ultra-cold storage, where distribution chains require freezers that maintain -70°C during transit for vaccine stability.

Automation and monitoring systems have greatly enhanced productivity, especially in pharmaceuticals. Humidity, airflow, and particulate matter are tracked in real time to comply with the stringent regulations of Good Manufacturing Practice (GMP) standards of the industry. Along with precision engineering, data-driven oversight guarantees consistent pharmaceutical production that meets strict legal standards, protecting public health while bolstering medical advancement.

Compliance with 3-A Sanitary Standards

The 3-A Sanitary Standards, set by the 3-A Sanitary Inspection, Inc., focus on the cleanliness of equipment used across the globe in the food, beverage, and pharma industries. As a benchmark with worldwide recognition, these standards pay the most attention to ensuring these pieces of equipment are ‘cleanable’, ensuring no further contamination occurs to the end products. In compliance with the 3-A’s, equipment is designed with clean-in-place (CIP) or sanitize-in-place (SIP) capabilities, which do not require disassembly of the unit and offer reliable and consistent cleaning processes.

Take, for example, the common compliant equipment’s use of stainless steel, which makes selection easy because the material has a nonporous surface and is corrosion resistant. Studies conducted also show how equipment with 3-A Sanitary Standards is maintained, risks of microbial risks, going as far as 90% in contamination reduction when benchmarked against non-compliant systems. These standards also focus on mandating the removal of dead zones or hard-to-clean areas in any piece of equipment used, which allows thorough sanitization. Compliance helps as much as the manufacturer and the consumer give emphasis on operational risk reduction, versus growing demands for safety and quality as an assurance.

How Are Sanitary Valves Designed for Safety and Cleanliness?

Sanitary valves are constructed from materials like stainless steel, which are durable and hygienic, and feature smooth, crease-free surfaces to prevent the accumulation of contaminants. Such valves include easy disassembly for thorough cleaning, ensuring no dead zones where bacteria can collect, avoiding areas with bacteria. Stricter hygiene requirements like those from the FDA or 3-A Sanitary Standards are also met, guaranteeing safety and cleanliness.

Stainless Steel Construction and Valve Body Design

The preferred material for sanitary valves is stainless steel owing to its great resistance to corrosion, durability, and ease of cleaning. Its 304 and 316 grades are particularly popular for manufacturing valve bodies because they can endure harsh environments like exposure to chemicals, high temperatures, and fluctuating pressures. For instance, 316 stainless steel, which has molybdenum, adds greater resistance to corrosion from chlorides than 304 does.

The design of the valve body also significantly affects the performance and hygiene standards. Smooth, continuous seams that eliminate the risk of contamination are created by the use of orbital welding during construction. In addition, end surfaces are usually polished to a specified roughness average (Ra) to smooth below 0.8 micrometers, which helps stop residues or bacteria from accumulating. Such features are critical in the food and beverage industry, as well as pharmaceuticals and biotechnology, where hygienic conditions are highly important.

Features That Make Sanitary Valves Easy to Clean

Sanitary valves are constructed with cleaning and servicing in mind. Their smooth, crevice-free construction is their most distinguishing feature, along with minimum lines that may harbor residues or contaminants. Most sanitary valves come with Clean-in-Place (CIP) technology, removing the need for disassembling the valve for cleaning. This greatly reduces time and labor in operational workflows.

Additionally, BPE compliant hygienic gaskets and seals, as well as FDA or 3-A Sanitary Standards gaskets are other crucial considerations. These help form secure connections that are leak proof, while remaining accessible for inspection and routine cleaning. Moreover, valve designs have also incorporated features that optimize fluid flow to prevent stagnation, reduce microbial growth, and ensure complete drainage.

The systems showcase the levels of achievement reached by automated cleaning protocols in contemporary sanitation systems. These systems can surpass a 99% cleaning efficiency for numerous applications, and greatly reduce water consumption, as well as energy expenditure when compared to manual methods. The application of polished finishes, including but not limited to Ra 0.4 micrometers for critical applications, actively contributes toward ease of cleaning by meeting the requirements of a surface that is non-porous and resistant to deposits. These features combined make the sanitary valves easy to clean and retain useful hygiene for a long period of time in harsh industrial surroundings.

Maintenance of Sanitary Valves for Optimal Performance

To ensure the longevity and optimal functionality of sanitary valves in industrial settings, proper maintenance is key. Inspections must be done regularly to check for any signs of wear, corrosion, or residue that can inhibit performance. In addition, valves must be split cleaned after every production cycle in order to maintain hygiene. Stainless steel cleaning agents compatible with the valve’s material should also be used in order to prevent chemical degradation.

Maintaining operational efficiency requires the prevention of routine downtimes, and up to 30% have seen improvement framed by statistics. Adopting a plan where seals and gaskets are replaced periodically can minimize leaks and tighten the seal. Moreover, restoring motion and lubrication to the moving parts of the valve will further resolve friction wear and valve component lifespan. By following the aforementioned guidelines, hygienic valves remain capable of working at optimal performance.

What Should You Consider When Selecting the Right Sanitary Valve?

For the right sanitary valve selection, pay attention to the following factors:

- Application Requirements: Identify what exactly you need the valve for: flow control, pressure regulation, or temperature control. Make sure the valve fits your process requirements.

- Material Compatibility: There are various materials of construction (like stainless steel) that might be used for food and pharmaceutical grade valves. Make sure you select a valve that will not be corroded by the handled product.

- Hygiene Standards: Check that the valve is sanitary in accordance with applicable industry standards, for example, FDA or 3–3-A standards, and preserves product safety.

- Ease of Maintenance: Choose a valve that can sustain low maintenance for a long period of time. Ensure the valve can withstand the operating pressure, temperature, and usage frequency.

- Durability and Performance: Select a valve that you expect to last your for a long time while looking at the operating pressure, temperature, and frequency of use.

Analyzing these criteria will help you choose a sanitary valve with optimal, safe, and dependable functioning.

Matching Valve Type to Specific Process Requirements

While selecting a valve type, I address the particular needs of the application. I consider the fluid’s characteristics, its operating temperature and pressure as well as the required level of cleanliness. For instance, high viscosity fluids may require diaphragm valves for ease and efficiency, while precise flow control measures may call for globe or needle valves. By integrating these considerations with the valve’s capabilities, I provide optimal performance and process efficiency.

Material Considerations for Different Applications

Choosing the appropriate material is one of the most critical steps to ensure the everlasting durability and effective performance of a valve in any application setting. In the steps to accomplishing this, one must take into consideration the properties of the fluid, environmental context, and operational demands that need to be fulfilled for the valve in question.

- Stainless Steel

Due to the hygienic nature of stainless steel, its applications range from crude chemical use to highly sanitary settings. Food and beverage factories need to maintain absolute cleanliness, and stainless steel is both corrosion-resistant and hygenic, thereby making it the ideal choice. Also, 316 stainless claims far more resistance to chloride corrosion than grade 304, so the latter is overused.

- Carbon Steel

As mentioned before, carbon steel has the most applications in the industrial world which require extreme levels of strength and stamina, all while being exposed to low level corrosive elements. High pressure environments such as pipelines carrying non-corrosive gases or oils are commonly made of steel carbon because of its endurance.

- PVC (Polyvinyl Chloride)

When cost is a factor alongside chemical compatability, PVC is often used. It is common to see it utilized within plumbing, as well as treating and purifying water because its structur is resistant to acids, alkalis, as well as various other chemicals, though it does have limitations at higher temperatures.

- Bronze and Brass

In plumbing fixtures as well as marine systems, Bronze and Brass are often used. This is due to their moderate corrosion resistance, low pressure capability, and overall excellent performance in low-pressure systems. Brass has the edge, due to its durability and ease of machining for potable water systems.

- Titanium

Titanium, even though pricier than other alternatives, has its uses in the aerospace, desalination, and chemical industries due to its extreme strength relative to its weight. Also, titanium stands out for its unrivaled strength to weight ratio and withstands harsh envoirnments like sea water, as well as chlorine containing substances.

Achieving long term efficacy as well as safety in an application is understanding the compatibility between the materials, the fluid dynamics of an application, and external factors like temperature and pressure. All of these factors working in synergy can greatly reduce maintenance costs as well as the downtime of the equipment while ensuring dependable performance.

Size and Connection Types for Sanitary Systems

Every component of a sanitary system is built to ensure the highest hygiene requirements, which makes the selection of appropriate sizes and methods of connections very critical. Sanitary piping is generally standardized within a range in diameters from 0.5 to 12 inches; however, specific industries such as food and beverage, pharmaceuticals, or biotechnology may have specific requirements. Smaller diameters are more often used for precision fluid transfer, while larger sizes are more suited for bulk fluid material transfer.

For optimal operational efficiency and cleanliness, connection types must be considered. Sanitary connections are most commonly tri-clamp, butt weld, threaded and flange. Better known as ‘quick’ sanitary connects, tri-clamped assembly connections are widespread because of the simpler and faster assembly and disassembly, giving way to effective cleaning. Flange connections may use lower working pressure, but all around larger pipe sizes and higher pressure. Connection materials must also consider factors such as system operating temperature and chemical exposure, ensuring long-lasting materials that withstand industry standards such as ASME BPE or 3-A Sanitary Standards.

The evolution of technology has enabled the creation of precision-manufactured connections that eliminate dead spaces or gaps that could harbor harmful microorganisms. Besides that, flow rate monitoring and block detection filters are progressively more integrated into sanitation systems and sanitary equipment, improving their reliability and overall efficiency.

How Do Sanitary Valves Contribute to Process Efficiency?

Smooth and uninterrupted flow of materials, along with preventing contamination, is ensured by sanitary valves, which in turn increases efficiency in processes. From their shape, pressure drops and blockages are reduced, aiding in smooth operations. Consistent operations are also aided by the level of precision engineering of the sanitary valves, since high-quality seals stop any possibility of leaks. This also aids in refraining from wasting valuable resources. Sanitary valves not only enable the swift cleaning of the valves themselves, but also reduce time when carrying out maintenance, greatly expediting production cycles.

Reducing Contamination Risks in Processing Lines

Reducing contamination risks during processing activities is important for food and beverage, pharmaceuticals, and biotechnology industries. Following hygienic design principles is one of the best options for avoiding contamination. The use of stainless steel equipment is a good example. It is preferred because does not corrode and its surface is smooth, which lowers the ability of microbes to thrive. Industry reports indicate that stainless steel can endure extreme scrubbing and sanitization, further protecting the safety of the product being processed.

Automation and monitoring systems also help to further reduce contamination risks. Important parameters such as temperature, pressure, and pH are monitored in real-time, which keeps optimal conditions, making sure corrections are automatically taken care of. Research indicates that the processing line, which has no access points for manual cleaning, is referred to as “cleaned-in-place” and is automated. Such systems are capable of optimizing water and chemical consumption by as much as forty percent while thorough cleaning occurs.

Furthermore, effective employee training in conjunction with strict compliance to operational procedures greatly improves the efforts made towards preventing contamination. Making sure that team members comply with the use of protective equipment, as well as protective hand hygiene, reduces the risk of human errors in contamination greatly. A combination of these measures with strong quality assurance procedures will guarantee basic food safety and consistent adherence to applicable regulations.

Minimizing Maintenance Downtime with Proper Valve Selection

The high functional efficiency and optimum valve maintenance are attained by selecting the correct type of valve. Newer designs of valves, like ball valves, butterfly valves, and control valves, are made to be more maintainable and durable. As an example, ball valves are tightly sealed and do not need to be lubricated while in use, hence they are less often. In addition, modern materials such as corrosion-resistant alloys and high-performance elastomers now make it possible to fabricate valves and other equipment from these materials, resulting in lower unexpected failures.

Recent industry reports suggest that plants that make use of advanced valve technologies branded with ‘smart valves equipped with a real-time monitoring system’ are able to reduce maintenance downtimes by thirty percent, and operational productivity by twenty percent. Moreover, the use of inline repairability as well as modular valves enables component-level servicing, thus allowing inter-component repairs without full system disassembly. These inline features lower component replacement time while improving overall maintenance efficiency. Investing using smart valves enables better performance by providing alerts for wear and premature failure, which improves long-term reliability while reducing costly emergency repairs and standby time.

Energy Efficiency Aspects of Modern Sanitary Valves

Modern sanitary valves are instrumental in improving the efficiency of energy use in fluid handling systems. These valves are designed with friction-lowering materials and smooth, aerodynamic flow paths, which minimize the system’s energy expenditure by reducing pressure drops. For example, some studies show that valves with optimized internal geometry can reduce energy loss by as much as 20%. This is accomplished while ensuring there is working energy within the system. Also, the addition of automated control systems allows for regulated, precise flow control, which prevents excessive use and wastage. Stainless steel and food-grade polymers deliver mechanical strength and thermal insulation, requiring less energy to maintain consistent operating temperatures. These design features aid the sanitary valves to align with eco-friendly approaches, aiding industries in reducing carbon emissions while drastically cutting costs.

Reference Sources

- “The Hygienic/Sanitary Design of Food and Beverage Processing Equipment” (2020) – This chapter discusses the criteria for sanitary design in food equipment, emphasizing the importance of hygienic design to ensure safe food processing. It covers fabrication, installation, and regulatory requirements, providing a comprehensive guide for maintaining cleanliness and efficiency in food processing1.

- “Improving the Hygienic Design of Valves” (2016) – This chapter highlights the role of sanitary valves in modern food processing systems. It details the design features that prevent contamination and ensure easy cleaning, focusing on the impact of valve design on product safety and system efficiency.

Frequently Asked Questions (FAQs)

Q: What are the main applications of sanitary valves in food processing?

A: Sanitary valves are used extensively in food, beverage, pharmaceutical, and biotechnology industries where hygiene is paramount. They control the flow of liquids, gases, and even some solids while maintaining strict cleanliness standards. Specifically, sanitary valves are essential in processes like pasteurization, fermentation, CIP (Clean-in-Place) systems, filling operations, and any application where product purity must be maintained. These valves are specifically designed to prevent bacterial growth, product contamination, and cross-contamination between batches, making them crucial components in maintaining product safety and quality.

Q: What features of sanitary valves make them suitable for food and beverage processing?

A: Sanitary valves are built to meet stringent hygiene requirements with several key design features. They typically feature polished surfaces (usually 32Ra or smoother finish) to prevent product adhesion and bacterial growth. These valves are designed for easy disassembly and cleaning, with minimal crevices where bacteria might hide. Materials used are non-toxic, non-absorbent, and corrosion-resistant—usually 316L stainless steel sanitary grade. Additionally, sanitary valves are built with self-draining capabilities to prevent liquid pooling, FDA-approved seals and gaskets, and design compliance with 3A sanitary standards and other regulatory requirements. Many models also feature a Clean-in-Place (CIP) and Sterilize-in-Place (SIP) compatibility.

Q: When should you use a sanitary grade valve instead of an industrial valve?

A: You should use a sanitary grade valve whenever your process involves products for human consumption or pharmaceuticals. Specifically, sanitary grade valves are designed for applications where cleanability, prevention of contamination, and compliance with health regulations are essential. Industries that rely on sanitary valves include food and beverage processing, dairy production, pharmaceutical manufacturing, biotechnology, cosmetics production, and any process where the product must remain pure and uncontaminated. If your operation must meet FDA, 3A Sanitary Standards, USDA, or similar regulatory requirements, sanitary valves are mandatory rather than optional.

Q: What types of sanitary grade valves are commonly used in processing facilities?

A: Several types of sanitary valves are used in processing facilities, each serving specific functions. Ball valves provide quick on/off control with minimal flow restriction. Butterfly valves (featuring a rotating valve disc) are ideal for large diameter applications and offer economical flow control. Diaphragm valves excel at handling high-purity applications and slurries. Check valves prevent backflow in systems. Gate valves provide precise flow control for applications requiring accurate regulation. Pinch valves work well with abrasive or viscous fluids. Sanitary control valves are specifically designed for automated processes requiring precise flow regulation. Relief valves protect systems from over-pressure conditions. The selection depends on the specific process requirements, fluid properties, cleaning protocols, and regulatory compliance needs.

Q: How do you know which type of valve is right for your particular application?

A: Choosing the right valve for your needs requires consideration of several factors. First, evaluate your process fluid’s characteristics (viscosity, temperature, pressure, abrasiveness). Next, consider your cleaning requirements and protocols (CIP/SIP compatibility). Review your regulatory compliance needs (3A, FDA, ASME BPE). Assess your process requirements (flow control precision, automation needs). Analyze installation constraints (space limitations, connection types). Consider maintenance requirements and accessibility for repairs. Energy efficiency and operating costs may also be important factors. Many facilities benefit from consulting with valve specialists who understand both sanitary requirements and process engineering. The right valve should provide reliable operation while maintaining the sanitary integrity of your process.

Q: What maintenance practices are required for sanitary valves?

A: Proper maintenance of sanitary valves is essential for both operational reliability and sanitary integrity. Regular inspection of seals, gaskets, and O-rings for signs of wear is critical, as these components should be replaced before they fail. Implementing scheduled preventive maintenance based on usage frequency and severity helps prevent unexpected failures. Proper cleaning and sanitization according to validated procedures (often using CIP/SIP systems) ensures sanitary conditions are maintained. Documentation of all maintenance activities is important for regulatory compliance. Staff should be trained in proper disassembly, inspection, and reassembly techniques specific to sanitary valves. Many facilities develop valve-specific maintenance schedules and procedures to ensure consistent performance while maintaining sanitary standards.

Q: How do sanitary control valves differ from regular control valves?

A: Sanitary control valves are specifically designed for hygienic applications with several key differences from standard industrial control valves. While both regulate flow with precision, sanitary control valves feature polished surfaces (typically 32Ra or better) to prevent bacterial growth, compared to the rougher surfaces of standard valves. They use FDA-approved materials and seals safe for food contact, whereas standard valves may contain materials unsuitable for food processing. Sanitary valves have streamlined designs with minimal crevices and self-draining capabilities, unlike industrial valves, which may have dead spaces. They’re built for easy disassembly, cleaning, and sterilization, and must comply with regulatory standards like 3A and ASME BPE. These differences make sanitary control valves more expensive but essential for food, beverage, and pharmaceutical applications.

Q: What are the cleaning requirements for valves used in sanitary applications?

A: Valves used in sanitary applications require rigorous cleaning protocols to maintain product safety. Most facilities implement Clean-in-Place (CIP) systems, which circulate cleaning solutions through the entire process system without disassembly. This typically involves rinsing, caustic washing, rinsing again, acid washing, and final rinsing steps. For more stringent requirements, Steam-in-Place (SIP) provides sterilization after cleaning. Periodic manual cleaning may still be necessary, requiring full disassembly, inspection, and cleaning of all components. Cleaning validation protocols must be established and documented to demonstrate effectiveness. Cleaning chemicals must be compatible with valve materials, and cleaning procedures must be validated to ensure they reach all product-contact surfaces. Regular verification of cleaning effectiveness through visual inspection, microbial testing, or other methods is also essential.

Q: What regulatory standards apply to sanitary valves in food and beverage processing?

A: Sanitary valves are built to meet several important regulatory standards. In the United States, 3A Sanitary Standards provide detailed specifications for design, materials, and surface finishes. FDA regulations (particularly 21 CFR 177) govern materials that can safely contact food. ASME-BPE (Bioprocessing Equipment) standards apply to pharmaceutical applications. EHEDG (European Hygienic Engineering & Design Group) guidelines are important for European markets. ISO 22000 addresses food safety management systems that include equipment requirements. NSF/ANSI standards certify equipment for food safety. Additionally, industry-specific requirements may apply, such as those from the Pasteurized Milk Ordinance (PMO) for dairy processing. Compliance with these standards is typically verified through documentation, third-party certification, and regular audits, ensuring that sanitary valves maintain the highest levels of product safety.