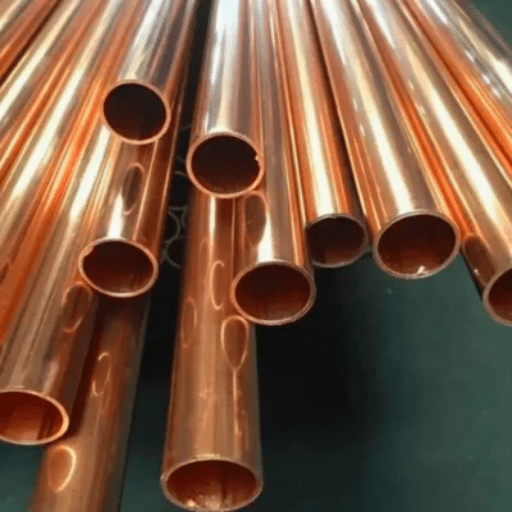

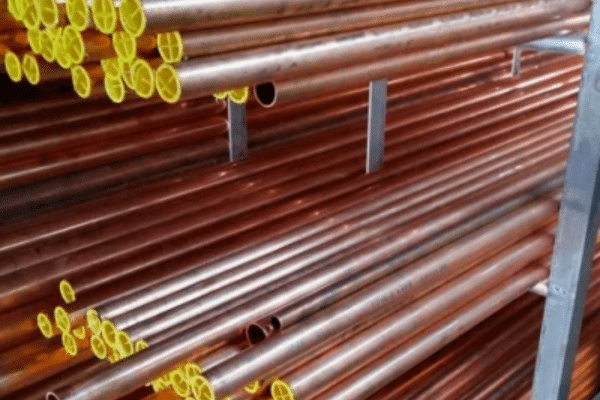

Seamless copper tubes are manufactured without any welded joints, ensuring a uniform structure throughout the tube.

+8615057563345

+8615057563345

Leading supplier of versatile copper tubes for HVAC, plumbing, and industrial needs. Our products offer exceptional durability, thermal conductivity, and corrosion resistance, adhering to global standards. Trusted by professionals, we deliver quality solutions for diverse applications at competitive prices.

Corrosion Resistance: Copper naturally resists rust and corrosion, even in harsh conditions like underground or high-humidity environments.

Hygienic and Safe: Copper has natural antimicrobial properties, making it a safe choice for water supply systems and medical gas applications.

Eco-Friendly and Sustainable:Copper is 100% recyclable, making it an environmentally friendly choice. Recycling copper requires less energy compared to producing new material, reducing the carbon footprint.

Easy to Work With: Copper tubes are lightweight, easy to handle, and simple to install. They can be joined using various methods, including soldering, brazing, and compression fittings.

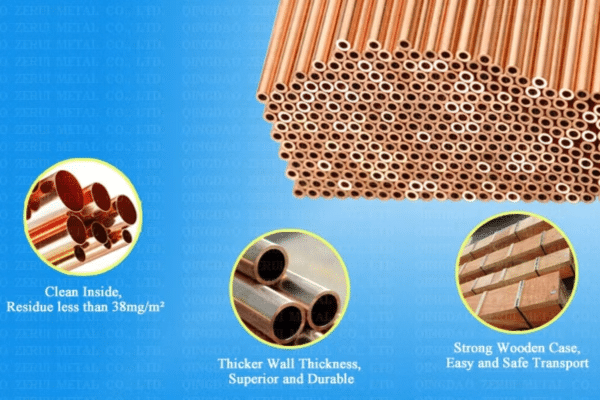

Our copper tubes are engineered to meet the highest standards of quality and performance.

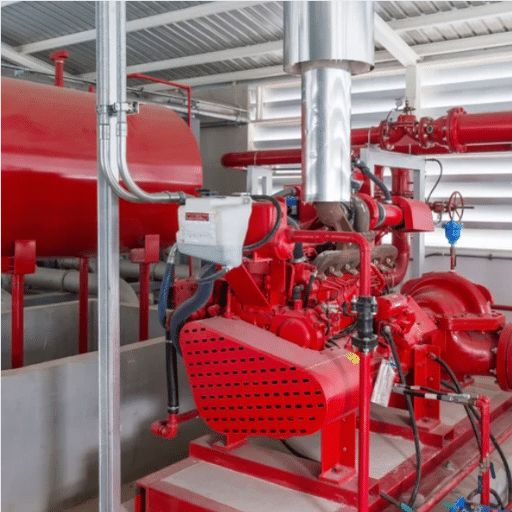

Copper tubes are highly resistant to corrosion, wear, and extreme temperatures, ensuring long-lasting performance in various environments.

Copper’s excellent heat transfer properties make it the perfect choice for HVAC systems, refrigeration, and heat exchangers.

Manufactured with tight tolerances and consistent wall thickness for reliable and efficient operation.

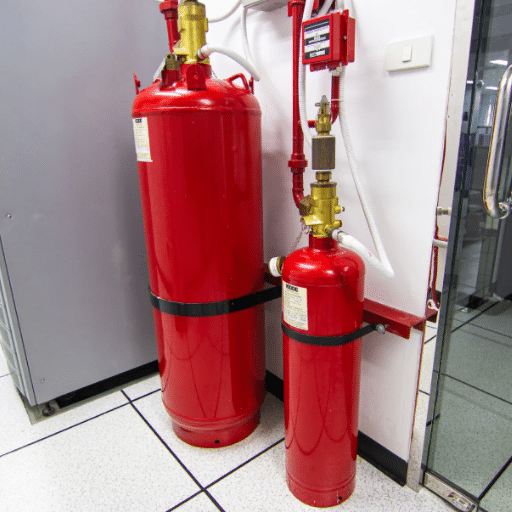

Suitable for a wide range of uses, including plumbing, HVAC, medical gas systems, and industrial applications.

Made from 100% recyclable materials, copper tubes contribute to sustainable construction and environmental conservation.

Lightweight and flexible, making it easy to handle and install in complex systems.

Seamless copper tubes are manufactured without any welded joints, ensuring a uniform structure throughout the tube.

Welded copper tubes are produced by forming and welding copper sheets or strips into a tubular shape.

Committed to providingthe highest quality copperproducts, including copperpipe, copper tube, andcopper fittings. Our copperand copper alloy productsundergo rigorous testingto ensure they meet orexceed industry standards.

Unmatched Quality: Manufactured to meet ASTM and ANSI standards, ensuring reliability and performance.

Versatile Applications: Suitable for residential, commercial, and industrial use.

Custom Solutions: Available in various sizes, wall thicknesses, and tempers to meet your specific project needs.

Sustainability: Copper is 100% recyclable, making it an eco-friendly choice.

Expert Support: Our team provides technical assistance and guidance to ensure the success of your project.

| Parameter | Details |

|---|---|

| Material Composition | Minimum 99.9% pure copper (C12200 alloy) |

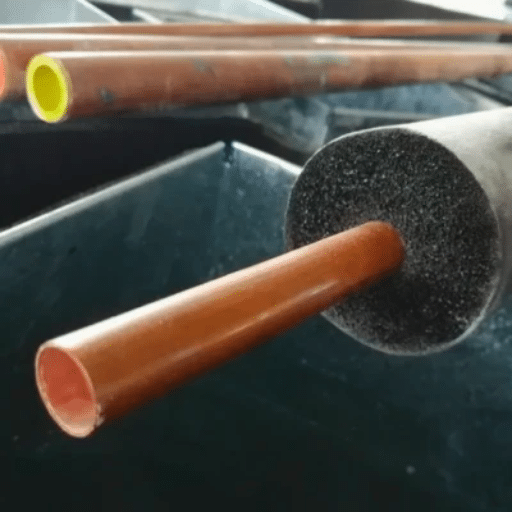

| Types of Copper Tubes | Type K (thickest), Type L (medium), Type M (thinnest), ACR, DWV |

| Wall Thickness | Varies by type: Type K > Type L > Type M |

| Available Sizes | 1/4" to 12" (outer diameter) |

| Length Options | 10 ft, 20 ft (hard-drawn); 25 ft, 50 ft, 100 ft (soft coils) |

| Pressure Rating | Up to 913 PSI (Type K, 1/4" size, at 150°F) |

| Temperature Range | Suitable for high and low-temperature applications |

| Finish | Smooth, clean surface; optional bright annealed finish |

| Standards Compliance | ASTM B88, ASTM B280, ASTM B306, ANSI standards |

| Applications | Plumbing, HVAC, refrigeration, medical gas, industrial systems |

| Connection Methods | Soldering, brazing, compression fittings |

| Corrosion Resistance | High resistance to rust and environmental degradation |

| Sustainability | 100% recyclable, eco-friendly material |

Copper tubes are the backbone of modern infrastructure, offering unmatched durability, thermal conductivity, and corrosion resistance. Whether for HVAC systems, plumbing, or industrial applications, copper tubes are the preferred choice for professionals worldwide.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

A: The outside diameter and wall thickness of copper tubing determine its pressure rating and flow capacity. Different applications require specific dimensions to ensure optimal performance, whether in plumbing, HVACR, or refrigeration systems. Choosing the proper size is crucial for meeting industry standards and ensuring efficient fluid transport.

A: Copper pipe products are known for their longevity, antimicrobial properties, and resistance to corrosion. Unlike plastic or PVC pipes, copper does not leach harmful chemicals into the water supply, making it a safer choice for drinking water and cooking applications.

A: Manufacturers such as Mueller Industries are recognized as industry leaders due to their commitment to quality and innovation. They utilize state-of-the-art facilities and advanced manufacturing processes, including forging and extrusion, to produce a full line of copper tubes that meet strict industry standards and regulations.

A: OEM applications play a significant role in the copper tubing manufacturing process, as many companies rely on original equipment manufacturers to provide tailored copper tube products for specific needs. This ensures high-quality components that meet the precise requirements of various industrial and commercial applications.

A: Copper tubing is frequently used in refrigeration systems for its excellent thermal conductivity and reliability. It is utilized in gas lines, refrigerant lines, and various fittings to ensure efficient heat exchange and optimal performance in both residential and commercial refrigeration markets.

A: The Hailiang Group is a prominent player in the copper tube industry, known for its commitment to sustainability and innovation. By producing high-quality copper products and investing in advanced technologies, they help reduce emissions and promote environmentally friendly practices in manufacturing.

A: Brass flow control products complement copper tubing by providing reliable fittings and valves that enhance system performance. These products are designed to work seamlessly with copper pipes, ensuring efficient fluid flow and reducing the risk of leaks or failures in plumbing and refrigeration applications.

Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd., specializes in high-quality stainless steel pipes and fittings, offering reliable solutions for industrial applications worldwide.