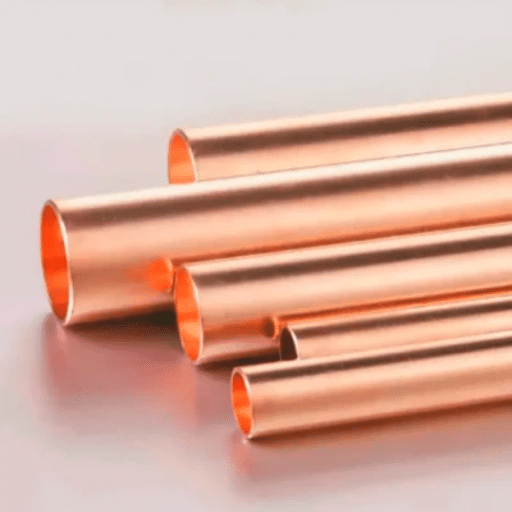

High-Quality Seamless Copper Tube Solutions

The world of copper tubing offers a myriad of options to meet the diverse needs of industries such as plumbing and air conditioning. Among these, the seamless copper tube stands out for its exceptional quality and reliability. This article delves into the features, advantages, and specifications that make seamless copper tubes an indispensable choice in modern applications.

What is a Seamless Copper Tube?

A seamless copper tube is a type of copper tubing that is extruded and drawn from a solid billet of pure copper, such as the C12200 copper alloy. This process results in a tube that is free from longitudinal seams. The absence of seams in these tubes significantly reduces the risk of leaks and enhances their capacity to handle high-pressure applications. Seamless copper tubes are commonly used in plumbing and air conditioning systems, where their superior strength and corrosion resistance are crucial.

Explore the Advantages of Seamless Copper Tube

Manufactured through cold drawing processes without welding or soldering seams, seamless copper tube offers unmatched structural integrity, reliability, and performance for critical applications where failure is not an option.

Superior Structural Integrity

Seamless manufacturing eliminates the weakest point in traditional welded tubes—the weld seam. No longitudinal joints means uniform wall thickness, consistent mechanical properties, and equal strength in all directions. This prevents stress concentrations and potential failure points.

Complete Leak Protection

With zero welded or brazed seams, seamless tube eliminates the risk of seam leaks from thermal cycling, vibration, or pressure fluctuations. Critical for high-pressure systems, medical gas lines, and applications where leaks could be catastrophic.

Exceptional Thermal Performance

Pure copper composition (99.9% Cu) delivers thermal conductivity of 401 W/m·K—significantly higher than aluminum, steel, or any plastic alternative. Seamless construction ensures uniform heat transfer with no thermal resistance from weld zones.

Easy Fabrication & Installation

Soft annealed seamless copper bends easily without kinking, reducing need for fittings by up to 70%. Can be soldered, brazed, or mechanically joined with standard tools. Hard temper provides rigidity for exposed installations. Cuts cleanly without burrs.

Detailed Technical Specifications of Seamless Copper Tube

| Nominal Size | OD (mm/inch) | Type K Wall (mm/inch) | Type L Wall (mm/inch) | Type M Wall (mm/inch) | Type L Weight (kg/m) |

|---|---|---|---|---|---|

| 1/4" | 6.35 / 0.250" | 0.89 / 0.035" | 0.76 / 0.030" | 0.64 / 0.025" | 0.13 |

| 3/8" | 9.52 / 0.375" | 1.24 / 0.049" | 0.89 / 0.035" | 0.71 / 0.028" | 0.23 |

| 1/2" | 12.70 / 0.500" | 1.27 / 0.050" | 1.02 / 0.040" | 0.81 / 0.032" | 0.36 |

| 5/8" | 15.88 / 0.625" | 1.65 / 0.065" | 1.14 / 0.045" | 0.89 / 0.035" | 0.49 |

| 3/4" | 19.05 / 0.750" | 1.65 / 0.065" | 1.27 / 0.050" | 0.89 / 0.035" | 0.67 |

| 1" | 25.40 / 1.000" | 1.65 / 0.065" | 1.27 / 0.050" | 1.07 / 0.042" | 0.9 |

| 1-1/4" | 31.75 / 1.250" | 1.78 / 0.070" | 1.40 / 0.055" | 1.14 / 0.045" | 1.25 |

| 1-1/2" | 38.10 / 1.500" | 1.78 / 0.070" | 1.52 / 0.060" | 1.27 / 0.050" | 1.64 |

| 2" | 50.80 / 2.000" | 2.11 / 0.083" | 1.78 / 0.070" | 1.52 / 0.060" | 2.56 |

| 2-1/2" | 63.50 / 2.500" | 2.41 / 0.095" | 2.03 / 0.080" | 1.78 / 0.070" | 3.65 |

| 3" | 76.20 / 3.000" | 2.77 / 0.109" | 2.29 / 0.090" | 2.03 / 0.080" | 4.96 |

| 4" | 101.60 / 4.000" | 3.40 / 0.134" | 2.79 / 0.110" | 2.54 / 0.100" | 8.13 |

| 6" | 152.40 / 6.000" | 4.06 / 0.160" | 3.56 / 0.140" | 3.18 / 0.125" | 15.84 |

Why Choose Our Seamless Copper Tube ?

- Our seamless copper tubes are crafted to meet the highest standards of quality and performance.

- With a focus on durability and efficiency, our copper tubing is manufactured from premium pure copper, ensuring unrivaled corrosion resistance and thermal conductivity.

- Our rigorous adherence to ASTM specifications, including ASTM B88, guarantees that our products are suitable for even the most demanding applications.

- Whether you are in the air conditioning, refrigeration, or plumbing industry, our seamless copper tubes offer a reliable solution that stands the test of time, providing unmatched value and performance.

Diverse Applications Across Industries of Seamless Copper Tube

HVAC & Refrigeration Systems

Plumbing & Water Distribution

Medical Gas Systems

Fire Sprinkler Systems

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Contact Us for Your Copper Tube Needs

Don’t wait any longer to enhance your systems with our superior seamless copper tubes. Request a quote today to receive competitive pricing and detailed product information tailored to your needs. Our seamless copper tubes offer the perfect blend of quality, performance, and reliability, making them an ideal choice for any application. Take the next step towards improving your systems’ efficiency and durability by contacting us now. Let us provide you with the best copper tubing solutions available in the market.

Frequently Ask Questions

Q: How is seamless copper tubing used in air conditioning?

A: Seamless copper tubing is commonly used in air conditioning systems due to its excellent thermal conductivity and resistance to corrosion. It is used for refrigerant lines, connecting evaporators and condensers. The seamless design allows for easier installation and better flow characteristics, which enhance the overall efficiency of the air conditioning system.

Q: What are the standard sizes available for seamless copper tubes?

A: Seamless copper tubes are available in various sizes, including standard diameters and lengths. Common sizes include ¼ inch to several inches in diameter, with lengths often offered in straight lengths of tube or coils. The length of the tube can be customized, and products are typically available in increments such as x 100 ft for convenience in larger projects.

Q: What specifications should I consider for copper tubing in medical gas applications?

A: When selecting copper tubing for medical gas applications, it is crucial to adhere to specific ASTM standards, such as ASTM B280 or ASTM B88. These standards ensure that the copper tubing is manufactured to meet safety and quality requirements suitable for medical use. Additionally, seamless copper water tubes are often preferred due to their reliability and durability under varying pressure conditions.

Q: How does wall thickness affect the performance of copper pipes?

A: The wall thickness of copper pipes plays a significant role in their performance, especially in high-pressure applications. Thicker walls generally provide increased strength and durability, making them suitable for demanding environments such as refrigeration and air conditioning. It is essential to choose the appropriate wall thickness according to the specific application requirements to ensure long service life.

Q: Can seamless copper tubes be used for plumbing applications?

A: Yes, seamless copper tubes are widely used in plumbing applications for both hot and cold water supply. Their resistance to corrosion and high durability makes them an excellent choice for plumbing systems. Seamless copper water tubes are particularly favored for domestic water service, ensuring safe and reliable delivery of water in residential and commercial buildings.

Q: What is the difference between hard drawn and soft annealed copper tubing?

A: Hard drawn copper tubing is produced through a process that increases its strength and rigidity, making it suitable for applications requiring high pressure. In contrast, soft annealed copper tubing is heat-treated to enhance its flexibility and ease of installation. The choice between these two types depends on the specific requirements of the application, such as bending capabilities and pressure conditions.