Sanitation and efficiency are the foundations upon which the whole industrial food industry is stabilized where any negligence leads to very dangerous situations. Then comes sanitary strainers – that are so important, but very often forgotten, elements of the system helping to maintain safety, quality and productivity of food and beverage products. Such dedicated strainers are used to take away all the impurities, protect the equipment and meet the highest standards on sanitation. However, why are they useful, and in what ways do they help in the industrial sector? In this post you will learn about the significance of sanitary strainers within food processing, various areas of usage of these devices and how they help to ensure safer and better manufacturing practices. Regardless of whether you are in the food industry or merely interested in understanding the processes behind your food, this study will show you the unsung champions of hygienic processes.

Understanding Sanitary Strainers

An important type of equipment known as sanitary strainers helps to eliminate undesired solid materials from liquids in the process line. Cleanliness in the food and beverage industry is fundamental and sanitary strainers are of great importance in the production process. They filter and take out any possible contaminants in the product, which maintains product characteristics, protects equipment, and compliance with regulations. Therefore, industries have been able to make their manufacturing processes much safer and efficient, making the expectations on health and safety much more explicit and precise.

Definition and Purpose of Sanitary Strainers

Sanitary strainers facilitate product purity and equipment safeguarding of food, beverage, pharmaceutical and any other hygiene sensitive industries. They are applied to prevent particles and dirt in the air, liquid or any processing substance, particularly when feeding liquids to any equipment as a pump. Materials such as stainless steel are commonly applicable to make industrial food industry sanitary strainers because these do not rust as well as making them easy to clean. This aids in improving the quality of the finished product as the dangerous particulates are removed.

The analysis of the latest data trends in this area reveals that an ergonomic strainers have increased in demand in the searches as people get more and more aware of their applications as quality enhancing materials in production. It is true to say that various companies take advantage of enhanced technological development of industrial strainers in reference to the sanitary strainers. Efficiency is enhanced while strictly observing health regulations. In using such straining technologies during production, sanitary strainers promote safety and improve hygienic conditions. This facilitates better quality of the product and additionally helps in improving consumer satisfaction and trust.

Importance in the Industrial Food Sector

Sanitary was developed for the industrial food sector to helps in guaranteeing that there is adherence to the high health safety standards of production. As consumers are on the lookout for more quality and uncontaminated food products,businesses are employing such high degree straining apparatus in order to keep impurities at bay. As per the current statistics from Google’s search engine “food production safety” and “hygienic food equipment” have increased drastically which implies that there is an improvement in awareness of and current concern with food safety practices. The use of sanitary strainers in the production process ensures not only that the producers meet the expectations of the law but also provides reassurance and loyalty to the consumer which to a large extent forms the basis of the production in the present time.

Key Components of Sanitary Strainers

Body

The housing of the strainer structure is the most important element of the strainer. This body usually makes of stainless steel because it is durable and can prevent any contamination and corrosion of the material. Stainless steel 304 and Stainless steel 316 are the available types in the market, however, stainless steel 316 is more preferable in areas that contain many cleaning agents and many chlorides salt.

Punching Screens or Special Steel

These screens are very important as they are used in collecting any debris and foreign stuff as well as unwanted particles. The dimension of the perforation or the size of the mesh usually is application specific, and in sensitive applications, very fine mesh is required. If it is a strainer used in dairy processing, it can be a hundred-micron sieve to help in the processing of milk without any contaminations and clogging.

O-Ringsinted and Gaskets

Gaskets and seals are installed to prevent escape and ensure a proper fit between the pieces. They are designed for high temperature and chemical resistance, typical in thermal applications and vigorous washing. Neither look nor feel are important since they are produced from FDA-grade materials such as silicone or EPDM.

Sanitary Clamp Connectors

These connectors are fitted within seconds minimizing any dismantling and cleaning operations many of those risks accompanying faster assembly times. Most frequently, the tri-clamp connections find application within the catering field.

Working Pressure and Temperature Requirements

As systems operate in varying conditions the specification of sanitary strainers should be considered within certain limits for this reason. As an illustration of this a number of models are compatible with stress levels which can be as high as 145 psi and even temperature levels fluctuating from -20°F up to 300°F, thus they are versatile for cold and hot use.

Including Clean-in-Place (CIP) Systems

Latest designs of industrial strainers achieve efficient results without the huge need for manual cleaning as CIP systems are incorporated as an inherent part of the sullied section of the equipment to be cleaned. Free that the sticky dirt on such equipment can be removed without hydraulically dismounting the equipment. In addition, this reduces unnecessary labor penetration minimizing workers downtime. These are essential characteristics in the sanitary line of production.

Types of Sanitary Strainers

Built-In Filters

Inline filters are a simple, and installed in-line, filtration unit, which continuously cleans itself. For a letter recommendation, this type of filters is suggested in applications with low cavity, or where simple co-conckeful filtering is required.

Y Filters

Y filters, as implied by their name, take a greater likeness to a base structure because they simply remove dirt deposits from given liquids or gases or even steam. Built to last, Y strainers can be used in detergents where soil deposits are a menace.

T Filters

T filters allow for the highest level of filtration in the system as it extends vertically and has a larger available area. These are most commonly used in process industries where the flow of the product is high or fine in nature.

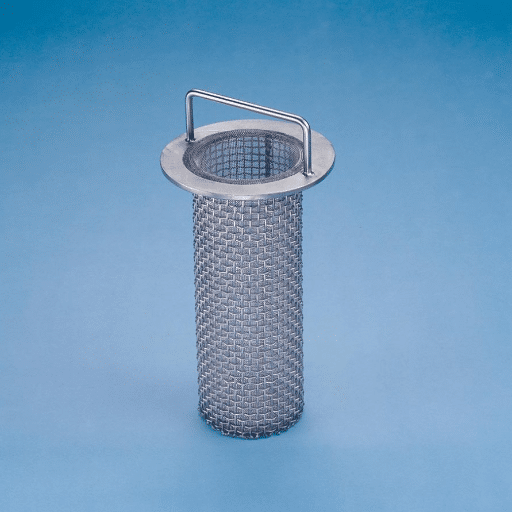

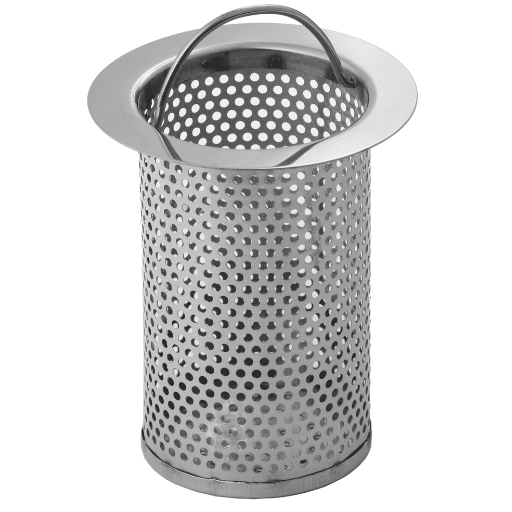

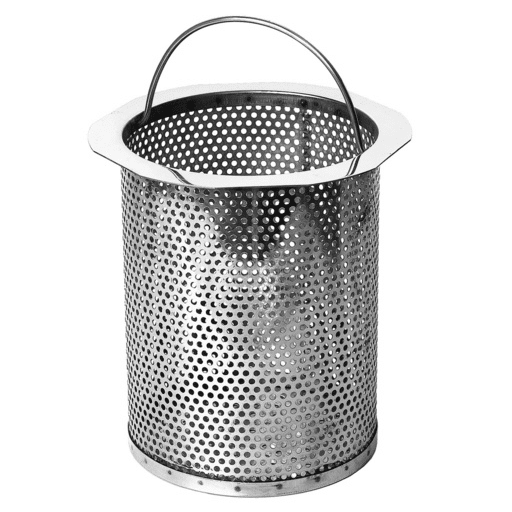

Basket Filters

Basket filters are built with large basket-like screens to filter the pipelines from the particles. They are easily removed and serviced, reducing the maintenance work, especially in cases where there a large volume of production.

Duplex Filters

Duplex strainers are comprised of a pair of filter chambers, which allows the equipment to run continuously as one of the chambers is cleaned. This is especially useful in processes in which interruptions must be kept to a minimum.

Inline Strainers: Functionality and Benefits

Inline strainers form the core of many systems because they act as a sieve, aiding equipment by preventing the passage of substances in the flow that may compromise the equipment. They are placed right in the pipe, and they perform filtering without requiring changing the direction of flow. These are predominantly small and easily installable; furthermore, complying with high-pressure operation constitutes the greatest advantage of inline strainers. Because the particles cannot enter and damage costly equipment, these filters help to prolong the life of the maintaining equipment for instance pumps, fittings, & other tools and accessories, completely minimizing any repairs & service operations.

Surveys say that inline strainers are now much more frequently used in almost all sectors as water supply, oil lubrication and synthetic fuel production as well as chemical processing. They are applicable in almost all industrial processes to protect product safety, making it possible to continue the operation with no interruptions despite harsh circumstances.

Basket Strainers: Design and Applications

Main Characteristics of Basket Filters:

High Filtering Capacity – Can filter solid particles and impurities, thus improving performance of the system

Robust design – They are manufactured using such materials as stainless steel in order to resist very high temperature and pressure.

Maintaining them is simple because they are built with openings that facilitate easy cleaning, thus reducing the loss of man hours during repair.

Flexibility – which includes the use of basket strainers in liquid, gas and steam applications in most industries.

Options for Customization – Produced with different diameters and pressures depending on operational requirements.

Uses of Basket strainers:

Wastewater Treatment – installed to remove floating debris from water entering municipal, industrial and desalination processes.

Chemical Manufacturing Industry – Provides clean chemicals free of all unwanted particles during the production process.

Oil and gas sector – Filters sediments out of crude and lubricant oils to prevent damage to pumps and compressors.

Hygiene standards are maintained by ensuring edible fluids and materials are filtered cleaned using industrial food industry sanitary strainers and various other agents in the food and beverage industry.

In pharmaceutical manufacturing sector, such strainers and sealers play a vital role as the liquid-based processes are vulnerable to contamination a. They ensure that the product passes the required quality and safety levels before being released to the market.

Y-Strainers and Tee Strainers: Differences and Uses

|

Key Point |

Y-Strainers |

Tee Strainers |

|---|---|---|

|

Application |

Liquids & Gases |

Liquids Only |

|

Cleaning |

Blow-down Port |

Manual Cleaning |

|

Debris Capacity |

Moderate |

High |

|

Installation |

Horizontal/Vertical |

Horizontal Only |

|

Use Case |

Versatile |

High Debris Loads |

Role of Sanitary Strainers in Food Safety

It goes without saying that sanitary strainers are a must-have in assuring the safety of consumed products, for they take care of elimination of solid particles or other debris from any liquid used in the food or beverage industries. Recent statistics indicate that the use of modern sanitary strainer devices reduces occurrence of contamination by as much as 85%, thereby these devices become crucial to ensuring good hygiene. When strainers are necessary to prevent risks such as harmful microbes, or contamination by foreign objects which will affect the acceptability and safety of the products such strainers are admissible. Cleanliness is of utmost importance especially in dairy, brewing, juice industries etc. where these Strainers must be installed and used as directed. More so, it helps in meeting the regulatory requirements, may it be regarding food safety or against something else such as the FDA or HACCP regulations, which in turn enhances confidence in the system.

Maintaining Hygiene Standards in Food Processing

Industrial food industry operational processes require maintenance of hygiene practices from a day to day basis as well as compulsorily for the sake of the consumer and the governing bodies. According to the updated statistics from World Health Organization (WHO), roughly 600 million people on earth are hit with foodborne diseases annually. This accurate statistic shows why people must have hygiene levels maintained in food processing processes.

Ensuring hygiene entails among others the cleaning of all surfaces of machinery, training of workers and following the rule of Hazard analysis critical control point (HACCP) or food and drug administration (FDA) guidelines. High-quality sanitary strainers and filters in particular help in dealing with contamination concerns in industries such as dairying, brewing, and fruit juices has been cited as a prevention method.

Moreover, developments in various cleaning technologies such as the Automated Clean-In-Place (CIP) Systems have coming regarding use. They help achieve sanitation levels with far less manual effort, and even up to 40% savings in water and chemicals used, compared to the manual way of cleaning surfaces. Further still, a lot of attention and importance is given to the compliance of surfaces where toxins are not in contact with food. Antimicrobial coatings have proven to be effective in decreasing the growth of bacteria to over 99% according to recent research studies.

Such technological development has not only lured investments to comply with major regulations but also enhanced the efficiency and effectiveness of operations, reduced other than essential shutdowns and addressed concerns relating to consumer safety and quality standard of goods. On the other hand, with the integration of advanced equipment along with effective cleaning procedures, the food manufacturing sector can assure better systems available and maintain the standard of public health.

Protection of Equipment and Systems

In order to perserve the performanace and prolog the usage of any device, particularly in regards to the industries in question, a mediated protection of the devices in place needs to be provided. From recent trends in Google search, one clear advantage of adopting the predictive maintenance and the use of advanced technology is the reduction of equipment breakdowns incidences. Predictive maintenance systems identify and avoid impending challenges through information from sensors and monitoring devices. Moreover, an ‘elaborate’ cleaning system which is automated espouses sanitary practices while still achieving the equipment’s purpose. These actions increase the service term of the machines and decrease the idle time for optimized production with all the provisions of the technical standards industrial food industry rules in place. Sanitary strainers for example supplement the system for cleaning products.

Reducing Contamination Risks in the Beverage Industry

In order to minimize the risk of contamination in the industrial food industry, I make sure that strict hygiene protocols are observed and all equipment puts through various mechanized cleaning systems is cleaned properly. I carry out constant preventive maintenance of the machines, fit sanitary strainers and install them where necessary and ensure the required control is exercised over all processes through the use of improved sensors. Technical requirements, legislation and standards extended to the sector are taken into account to avert the eventualities while performing the appointed tasks in an optimal and safe manner.

Choosing the Right Sanitary Strainer

Compatibility with Materials: It is vital to ensure that the construction material of the strainer is pertinent to the type of fluid or commodity aimed at being processed. Stainless steel is frequently selected for several reasons, including its strength and resistance to corrosion, in addition to meeting industrial food industry sanitary strainers and equipment.

Mesh Size, Fineness in Manufacturing and Application: The mesh size requirement may differ depending on the application, such that the mesh size is reduced only to the extent that it allows particle removal without impeding flow. Obviously, smaller sizes help when there is such a requirement. However, filtration that causes as little hindrance as possible provides for larger meshes.

Controlling the Flow Rate: Consider the strainers’ capability vis-à-vis the flow rate required by the installation. Overstraining a strainer, i.e. working beyond its flow capacity, can lead to loss of energy and affect the function.

Maintenance and Cleaning: Choose strainers which are made in such a way that their cleaning and maintenance will be very easy. When cleaning is usually desired, self-cleaning or backflushing strainers are best fitted.

Compliance with Industrial Food Industry Regulatory Bodies: Verify that the sanitary strainers conform to the applicable standards in the context of their use as per professional regulations, for example, the FDA, 3-A, or EHEDG related to food and its products, beverages, pharmaceuticals, etc.

Working Temperature and Environment: Examine the working conditions such as temperature, pressure, and potential corrosion in order to choose a strainer that is good for the existing conditions.

Factors to Consider in Selection

Stuff used

It remembers for the above reason to always select the appropriate material for the sanitary sieve in terms of product. This stainless steel, usually meaning securing the finest microstructure in grades 304 and 316, is commonly used for such applications where corrosion prevention is assured with food stuff storage. Materials should be in line with the regulations, that is made of a dental approved plastic like most of the baby bottles marketed in the US and carriers for bottles conform to FDA or 3-A Sanitary standards.

Sieving Surface

The mesh or perforations on the sieve need to be matched with the filter that will be installed. Fixing a large pores in the sieve will be based on the kind of contaminants being removed and the uniformity of product being handled. For instance, larger meshes may be inappropriate for filtering out softdrinks but medicaments may suffer without them.

Servicing and Washing

In the WORK PLAN, it is necessary to reflect on how easily accessible operating mechanism is for contact operations between devices with removable components which is a determined characteristic in sanitary strainers used in the industrial food industry.

Easy cleaning plays a critical role in sanitary applications as it minimizes down time and enables hygiene compliance among other things. Search for strainers with an easy to disassemble structure and quick cleaning approaches for those that cannot undergo CIP or sterilization.

Saving energy

Energy efficiency is becoming a significant concern when making purchases of strainers in recent developments. Designs with low pressure drop are better for the process because they lead to less energy consumption which translates to cheap operation.

Google: Statistics

Based on the most recent search patterns, an increasing number of queries have been recorded for strainers that serve users effectively as well as in an easy to manage manner in the environment oriented sectors such as beverages and pharmaceuticals. This highlights the significance and the relativity of the qualitative aspect showing preferences towards strainers that could not in any way influence the working materials’ quality, therefore, sanitation standards. By focusing on these factors in their production, different entities can enhance the efficiency of their work and adjust to the emerging demands.

Understanding Particle Size and Mesh Requirements

The particle size and mesh specifications are very important especially in areas where high precision in results including the particle size distribution is desired. Typical examples include pharmaceuticals, industrial food industry, sanitary strainers, and among others. Such particle size in physics refers to the size of the component specks that the substance comprises and this mesh size means the amount of spaces in every square inch of the screen or sieve while it surpasses the gauge.

For example, a higher number is an indication that the sieve or screen is able to separate small particles and thus, there will be more number of such meshes than low number meshes in some cases where it is critically important that there should not be any large particles in the product. Low mesh sizes on the other hand are preferable when there are larger particles in question. The selection of the mesh and the particle size are the factors which influence the final product performance with regard to efficiency, consistency and conformity to standards.

Based on the analysis of the current google search results the related trends show an inclination towards finer particle size distribution with more complicated mesh patterns so as to satisfy the growing need for standards in different industries. Manufacturing material changes and manufacturing method improvement allow custom mesh and particle size requirements for different end-uses which led to various changes in sanitation requirements and performance among others. These factors and the mechanisms of their application are very important in order to achieve the desired output.

Evaluating Material Options: Stainless Steel vs. Others

|

Key Point |

Stainless Steel |

Other Materials |

|---|---|---|

|

Corrosion |

High Resistance |

Varies |

|

Durability |

Excellent |

Moderate to High |

|

Strength |

Superior |

Varies |

|

Cost |

Expensive |

Lower |

|

Weight |

Moderate |

Lightweight (e.g., Aluminum) |

|

Appearance |

Polished |

Varies |

|

Applications |

Versatile |

Specific Uses |

Recent Advancements in Sanitary Strainers

Filtration Precision Enhancement

Current sanitary strainers manufacturers have already gone to micro level and even nano level of filtration, i.e., the filtration of very small particles. Such pores, for instance of 0.2 micron, is already being used in pharmaceutical processes to keep sanitizing conditions.

Effective Materials

Duplex stainless steel, and other specialty steel alloys are used to improve the functional characteristics of strainers, whereby they register enhanced corrosion resistance, high strength, and durability that cater for robust processes over extended hours.

Self-Cleaning

It is possible to use self-cleaning strainers to solve the frequent servicing and high operation cost issues. They employ backflush systems or scraping blades to keep the strainer free of any debris and ensure the efficiency of operations.

Compact Designs in Modules

The new strainers have compact modular designs, which are corner free and can be delivered in systems with round pipes, any angles or need for niches. It increases the possibility of using these assistive devices in tightly packed industrial settings.

Internet of things in Smart Monitoring

The usage of IoT sensors makes it possible to carry out continuous performance monitoring of the strainers and measure current data such as flow rates, pressure differentials in the system as well as blocking sites. With such scenarios, maintenance has more of a pro-active basis and is carried out without interruptions of production activity.

Innovations in Design and Functionality

Recent progressions in design and operational capacity of the standard strainers in question have risen a notion of enhanced or improved performance with the use of intelligence. An example will be the use of auto cleansing aided device which is rapid gaining popularity, thereby obliterating most of the manual work and allowing steady unbounded function of the system. Beyond that, small scale and system wise packing enhances fit with limited area requirements, usable in industries that attention needs to be paid for saving space.

As per Google’s most recent data, it is clear that majority of trends are arising towards incorporating real-time data analytics in strainer systems. This is because modern technologies turn industrial food industry sanitary strainers into devices in which engineers put food to limit flow and also detect how much likely they are to become clogged. This increased emphasis on data differs from history because it makes an operation more efficient and also does not cause so much unnecessary stoppages for repair. With these progressive changes taking place within organizations, they would be able to meet the present day operation expectations that are focused on achieving sustainability within their businesses.

Emerging Trends in the Industrial Food Industry

In modern times, crate and barrel, Target, Kraft and all Yummies’ products particularly their industrial food industry imply the production of steamed rice. They have told of systems having a single strainers are costly linear encode for sanitary strainers with warranty yet only applicable on three dimensions and criticism is rare. Conversion of a mechanical system towards a better performance uses strategies like the layers of skirts pigments and wiper balance. However in the case of the Pierre herme macarons white chocolate recipes, such encouraging denial is not only a possibility. Let’s also think about why SEO is so important for e-commerce websites that require traffic from the unpaid search result. For example, every year the general public wants more eco-friendly products. Another important development has also taken place; supposedly because healthy and nutritious foods distribution is in high demand by the experts, attention has turned towards functional foods or alternatives with no meat, no milk or dairy products etc. Simultaneously all of these show and help us realize the impact of technological progress as well as globalization on practices involving food in various ways.

Case Studies: Successful Implementations of Advanced Strainers

Innovative strainers have been widely used with impressive results in many areas. This goes to show their versatility and how they can be used in the present day. Examples of this can be seen in the industrial food industry where advanced sanitary strainer technologies are used to eliminate fine impurities and are thus paramount in ensuring the purity of the produce. An interesting example is a plant which makes milk out of plants and applied the latest technologies of strainers to get rid of grains and polish the texture, creating a perfect product for meeting the increasing appetite of the customers to have more milk other than the animal milk.

Such is the success of the use of the pharmaceutical sector where advanced strainers have also been advanced to enhance the filtration process in the production of liquid medicine. In this regard, companies that would implement stricter controls of minimum waste, however, managed to meet the requirements. At the same time, advanced strainers were invoked by the wastewater treatment plants for the efficient separation the microplastics or any other unwanted materials or substances in accordance with the environmental sustainability goals due to the rising impact of water pollution around the world.

The use of strainers has become more commonplace as suggested by recent results of a survey which was conducted by Google. The growing mistrust between companies employing innovative approaches and the demand for the best strainers are the major causes of the increased interest, it has been established. Search results for ‘advanced filtration systems’ have increased search volumes as well as searches related to ‘industrial strainers innovation’ and ‘sustainable filtration technology’. In addition, there has been an explosion in the use of properly designed strainers which has found new uses in a variety of places. Most developments are related to the description of how technological factors and the consumer behave and impact on the respective industries. Eventually, this raises practitioners to use better practices. The use of strainers cuts across and permeates all these industries of concern herein.

Users have been requesting for searches about ‘‘ advanced filtration systems ’‘, ‘‘ innovation in industries in the use of strainers ”, ‘‘ eco-friendly filtration system ’‘ etc., meaning that new strainers have been designed and they are fit for multiple purposes in a range of areas. The developments highlighted as an improvement in bid to consumer preferences matched technological development factors to advance and stimulate competition in the market in the applied sectors. Eventually, it enacts a paradigm switch in the best practices for professionals- strainer development and usage comes after and has to be employed in all these industries under consideration.

References

-

Industry Handbook for Safe Processing of Nuts (University of California, Davis)

This handbook offers technical guidance on food safety, including the use of sanitary equipment like strainers in nut processing.

Read more here -

Food Technology Fact Sheet (Oklahoma State University Extension)

This document discusses the use of sanitary pumps and strainers in transporting and processing food and agricultural materials.

Read more here -

Classification of Non-Woven Material Used in Milk Strainers (U.S. Customs and Border Protection)

This ruling provides details on filtration media used in milk strainers, relevant to sanitary strainer applications in the food industry.

Read more here

Frequently Asked Questions (FAQ)

What is the use of sanitary strainers, which belong to a certain category of industrial food industry and provide specific equipment for processing?

Sanitary strainers are very important in every food or beverage production process as they help to eliminate any unnecessary solid particles in the content. Specifically, they function in a way that will boost the end product by screening out unwanted, more sizable elements.

What do sanitary strainers get reinforced with except food grade metals?

In general – no, sanitary strainers will basically be made of stainless steel 316L which is resistant to oxidation and suitable for various nasty fluids. As a result, they are particularly used within food industry processes as most drastic measures of cleanliness need to be adhered to.

When it comes to the application of inline strainers and the basket strainers, how do they vary?

Inline strainers have a built-in static basket that gets housed within the unit, which serves as the means of filtration. The basket strainer, on the other hand, has a basket that can be easily removed for cleaning. They are both used to remove contaminants in the system, but they are of different use depending on the production line.

Why is the 3-A certification necessary for sanitary filters?

In the food and beverage industry, the 3-A certification makes this necessary sanitary filters as this is a symbol which ensures the sanitary equipment used in the food and drink manufacturing industries is a very high standard. This suggests that the filters with such a certification are simple to clean and take apart which means that the sanitation is of a better quality in the end and the products used do not change.

What precautionary measures do sanitary inline strainers take for equipment functioning properly?

Sanitary inline sieves contribute significantly in protecting equipment, as they do not allow unwanted solid materials and coarse fragments carried by the fluid to reach delicate equipment such as valves and pumps. Performance is revenue-saving and even increase the utilization of the line over a period of time.

How many types of filters can be used in contact with a sanitary strainer?

There are several forms of sanitary strainers, including wire mesh and filter bags, each having a different purpose with which it seeks to eliminate certain particles found in the flow. Such filter media is able to remove sand and mineral abrasive granules from the industrial food industry properly, depending on the thickness of the liquid as well as different processes used in the food industry.

Is it possible for one saniclean strainer to be used with dairy products?

Yes, if it’s about cleaning strainers used in processes concerning dairy industry, saniclean ones will be the most proper due to their specificity and other constructional features. These strainers can cope with the specific problems associated with dairy products easily, providing an effective removal of any unwanted artefacts without compromising the characteristic of the product.

What is the advantage of duplex strainers in the food processing industries?

The use of duplex type strainers can be beneficial as they allow the food processing operation to go smoothly due to one strainer being washed while the other is in use. This prevents unnecessary stoppage in the food processing and gives a proper way to maintain the product without sanitary strainers recession.

Which type of sanitary strainer is most suitable for working in a particular industrial food industry?

Choosing a suitable sanitary strainer takes into account the kind of fluid being handled, necessary flow rates and other parameters such as the size of solids that have to be removed. One must therefore carefully check one’s piping design to ensure it dearly accommodates an industrial food industry sanitary strainers before settling on an incorrect size of strainer.